Precision air conditioning can meet your toughest telecom room and spot cooling challenges.

The communications industry continues to evolve with endless technology rollouts, each targeting enhanced productivity. With applications reaching into the core processes that support critical finance, logistics and e-commerce functions, these new systems must also provide continuous reliability. When you consider that even a minute of downtime can cost millions of dollars, it goes without saying that keeping systems up and running becomes essential.

And one of the keys to continuous availability is an infrastructure that can protect sensitive electronics from the heat generated by today's telecom equipment. Increasingly, faster microprocessors and compact equipment size-on both the component and system level-produce growing heat densities. Today's smaller, more sophisticated systems simply contain more computing power.

Knowing how to plan and install the right precision air conditioning can provide an environment that keeps these heat-generating communications systems running around the clock.

When did it get so hot in here?

Over the next six years, heat densities in data center and communications spaces are predicted to grow anywhere from one to four times the current levels. The largest percentage in heat density growth will come from communications equipment, which is expected to increase as much as 500% by 2010. This means that a facility using 100 W per-square-foot today may have densities escalate to as high as 500 W per-square-foot.

To handle growing heat densities, it is a common misconception that equipment cooling can be achieved simply by adding greater cooling capacity. But this will not reduce heat build-up within a confined space, such as an enclosure, where more direct heat removal is necessary. This is of particular concern for facilities where equipment is densely packed in racks installed next to one another. It's essential to plan and develop facility and spot cooling solutions that offer proper environmental control and protection. The solution you choose should also be scalable and adaptable to accommodate growing demands on cooling systems and dynamic business requirements.

Precision vs. comfort cooling

A distinction should be made between comfort cooling and precision air conditioning. For sensitive electronics, it's mandatory that you supply air that is filtered from harmful airborne particles and that provides precise control over both temperature and relative humidity.

Excess humidity can corrode switches and circuits in communications equipment, leading to catastrophic failure. On the other hand, not having enough humidity in the air supply can create static electricity with similarly devastating consequences. There is also an equally important temperature range for optimum performance of communications equipment. As for airborne particles, a build-up on circuits can lead to arcing, which can also damage sensitive electronic systems.

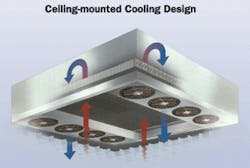

A ceiling-mounted cooling design can cool high-density applications with zones of up to 500 W per-square-foot.

Precision air conditioning goes beyond comfort cooling to provide complete environmental safeguards with accuracy and dependability. To ensure continuous availability, precision air conditioning must be implemented in critical spaces where communications equipment is located.

Riding on air

The current practice for cooling telecommunications facilities and spaces is to use air as the transport medium. This is accomplished with remote (outside of critical space) air handling systems that use overhead air distribution ducts, or multiple precision air conditioning units (in critical space) that use overhead ducts, or systems mounted on raised floors that supply air through the underfloor plenum. While these air conditioning systems may be effective for many facilities with as high as 100 to 200 W per-square-foot loads, additional support solutions may be needed as spot densities rise to 500 W or more. As heat densities escalate, duct dimensions, air changes-per-minute, and floor space occupied by cooling systems will eventually reach unobtainable levels.

To understand "hot spots" begins with recognizing that there is a direct relationship between power consumption and the amount of heat dissipated by electronic equipment. In addition, there are substantial differences in the amount of power consumed (and subsequent heat generated) among the different types of equipment used in today's communications networks and data centers.

To this point, it is not uncommon for different zones in a communications facility to vary in density by a factor of five or more. For example, a facility with an average density of 150 W per-square-foot may have areas as high as 250 W or as low as 50 W per-square-foot. If projected heat density trends continue, this differential could increase to a factor of eight or more within the next five years. Given this proposed trend, if a facility had an average density of 200 W per-square-foot, spot densities could be as high as 533 W, and as low as 66 W per-square-foot. These variations in densities only further increase the difficulty of adequate heat removal through traditional methods.

Supplemental cooling alternatives

New cooling methods are needed to handle emerging systems that have power densities in excess of 200 W per-square-foot. You may find that more than one solution will be needed, such as precision air conditioning along with some form of localized cooling to provide heat removal for high spot density loads.

In addition, other mediums may be more effective in transporting heat from the local environment. Fluids and refrigerants are good alternatives for the absorption and transport of heat. Heat densities for communications spaces will most likely increase gradually over time as old equipment is updated and newer systems are added. Therefore, it can be expected that alternative and multiple solutions will be needed, given the scope and extent of the required heat removal. Here are several design options:

- FAN-ASSISTED ENCLOSURES

There may be several ways to accomplish the task of providing more efficient cooling for high heat densities in rack environments. One possibility is to draw underfloor air directly into the enclosure, and then discharge it through the upper rear of the enclosure. This method takes advantage of raised floor environments where cool air is pulled from the underfloor air distribution instead of aisle areas. There is less mixing of air temperatures, and the hot air is discharged closer to the return side of the air conditioning system.

- ENCLOSURE-MOUNTED COOLING SYSTEMS

If air circulation is not sufficient to ensure proper cooling, another transport medium may be required. One approach would include a system that consists of a fin and tube cooling coil plus small fans commonly used in HVAC applications, which are mounted on an enclosure's rear access door. Heat transport is accomplished via water or a dielectric fluid. This method is designed to absorb the heat released as it leaves the enclosure (and prior to re-entering the space), thereby making the cabinet "load neutral." In doing so, it has the added benefit of not reaching the capacity of the precision conditioning system (note the nominal temperatures entering and exiting the enclosure in the figure on page 30).

Enclosure-mounted cooling systems are designed to absorb the heat released as it leaves the enclosure, and prior to re-entering the space, making the cabinet "load neutral."

Designs of this kind have been proven to absorb as much as 8,000 W (27,300 BTUHs) of heat from an enclosure. As illustrated in the figure, integrated fans pull the dissipated heat through the cooling coil. Flexible hoses and quick connect fittings (to a chilled water source, typically at 45°F, or other heat transport medium) on a hinged rear door provides the necessary service access to the rear of the enclosure.

To ensure that no condensation occurs, the fluid temperature must always be above the dew point of the air. For this reason and to maintain proper flow, system pressures, fluid purity and isolation from the main cooling loop, you should use a Coolant Distribution Unit (CDU). The CDU contains a fluid-to-fluid heat exchanger, pumps, control valves, and controls. As the CDU provides fluid to multiple enclosure units, it would likely have a total capacity of 100 to 200 kW.

- CEILING-MOUNTED COOLING

Since traditional air conditioning may not provide the needed ducting or capacity for proper cooling of certain localized areas, a possible solution involves the use of modular ceiling systems that can be installed directly above high heat areas. These units would consist of fin and tube coils plus fans, which utilize a fluid or refrigerant as the heat transport medium. The figure on page 27 illustrates this type of ceiling unit design and functionality.

This concept includes movable fan trays to optimize air distribution for equipment that is situated below ceiling units. Designs of this type can cool high-density applications with zones of up to 500 W per-square-foot. Just as with the enclosure-mounted unit, the ceiling design will require that you use a CDU if fluid is used as the transport medium. If refrigerant is used for cooling, you will need a remote condensing unit, and variable capacity if multiple ceiling units are to be installed. Again, the refrigerant temperature must be maintained above the air dew point.

Other methods

These techniques are by no means a complete list of all current and future methods of cooling for high heat densities. Aside from the methods used on the facility or localized level, some server manufacturers are developing component-level solutions that reduce equipment heat densities. While this may decrease the heat dissipated by communications network equipment, it will not eliminate the need for precision air conditioning on either a facility-wide or direct level.

Monitoring and control of environmental systems is especially important, since small problems can quickly escalate into catastrophic failure. The latest solutions for monitoring of support systems include a variety of methods that can be used together for multiple paths of communication.

Out-of-band monitoring can be accomplished using a modem or a Web-based system, while in-band monitoring is achieved through an internal network connection. For continuous communications capabilities, an in-band connection can be used in conjunction with out-of-band access in the event that the network goes down or is not available.

Most network monitoring systems allow for management and control of infrastructure supports using either SNMP (Simple Network Management Protocol) or http access. Alarm notification and escalation, as well as the capability to shut down and reboot systems, are just some of the critical functions performed by today's monitoring and management technologies.

Power reliability and protection

For complete infrastructure support, your power protection must be just as reliable as precision air conditioning. With the loss of power, there is an instantaneous switch to an uninterruptible power supply (UPS). While the UPS is able to keep critical computers and components up and running, these units do not have the power available to run cooling systems. The temperature inside a data center may quickly rise due to built-in delays on HVAC restarts after emergency power generators have started. During this delay, the temperature can escalate to the point where reliability of critical systems may be compromised.

As this scenario illustrates, an infrastructure that provides continuous availability requires planning and design with both power and cooling in mind. While seemingly separate, these infrastructure support solutions are equally important to keep critical communications networks running smoothly. It is important to take an integrated approach to the planning and design of infrastructure support systems that address the unique needs of individual communications networks and environments.

Preparing for the future

Given projected heat density trends, the future appears more complex and demanding as far as heat removal is concerned. Precision air conditioning will need to be much more adaptable and flexible. There will likely be more than one primary cooling system, including one for the average load, and one or more for direct cooling for areas with high heat concentrations. Future remedies may include the use of a transport medium, other than air, to remove the heat-including water or non-conductive dielectric fluids. Individual manufacturers may choose specialized ways to achieve load-neutral equipment-spray cooling, very low temperature refrigeration, and two-phase boiling are a few possibilities.

Regardless of the technology or its application, preparing for growing heat densities will require careful planning for future growth of communications networks and the infrastructure supports that will be needed for years to come.

James Hall is telecom market manager for Liebert Corp., Columbus, OH. He can be contacted at (614) 841-6095 or by e-mail at [email protected].