Contractors who are proficient in the installation of Ethernet in office settings can adapt their expertise and find new business in the industrial world.

A number of technologies developed for the office are making their way to the factory. Ethernet, for example, has been fine-tuned in the office and is now becoming a major component of industrial networks. It's a new market opportunity for those who wish to service it, but be prepared—while the electrical component of Industrial Ethernet will be familiar to commercial networking installers, the physical side will be very different.

The use of Ethernet for industrial automation and its associated standardization work has grown dramatically. One of the main benefits of moving from legacy fieldbus to Ethernet is the ability to connect the front office to the manufacturing system; this is because Ethernet is not a proprietary communication protocol. The non-proprietary nature of Ethernet also lets engineers mix and match equipment from different vendors and get competitive bids. The combination of better office-factory communication and open standards has helped Industrial Ethernet gain growing acceptance.

Contractors who are proficient in the installation of Ethernet in office settings can adapt their expertise, and find new business opportunities, in the industrial world. The TIA standards that specify installation of communications cable and performance of the data center are being adapted and debated for use in Industrial Ethernet settings. Once ratified, TIA 1005 should provide a recognizable framework for contractors who wish to move into this field.

What's so different?

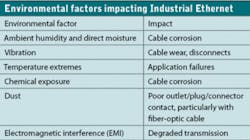

The biggest issues in Industrial Ethernet stem from the hazards to which networks are exposed. Two major factors contribute: Lack of climate control and the presence of other electrical equipment. While the network in an office or data center is protected from nature's elements by air conditioning and shade, most industrial environments lack such climate control. Excessive heat and humidity, for example, can impact the transmission media. Unshielded twisted pair cable, commonly used in office networks, can be damaged by prolonged exposure to sunlight. The electromagnetic interference (EMI) generated by electrical equipment causes noise that impedes network traffic. Also, RJ-45 connectors—a mainstay of corporate networks—are not designed for long-term performance in excessive heat or stress; their contacts can corrode and the locking tabs can easily break off.

Other factors include the distances over which a signal must be transmitted, which can differ significantly from an office setting. Industrial Ethernet cable may need to run a quarter-mile mile or more as it is routed through a large plant, around hazards, and from machine to machine and switch to switch. Unshielded twisted pair cable, typically used in offices, has a 100-meter maximum distance. While this specification originated to separate user transmissions and prevent collisions, today, the distance limitation is the result of power transmission. Network Interface cards (NICs) are designed for 100 meters. Beyond this distance, extra power is required, and added power generates noise that interferes with data transmission.

Multimode fiber is sufficient for up to 2 kilometers, but for distances over 2 to 3 kilometers, singlemode cable may be required. Yet fiber-optic cable brings its own set of challenges. The diameter of a singlemode fiber core, for example, is smaller than a human red blood cell. Fingerprints, or even dust in the air, can sit on the fiber-optic endface, causing reflectance and inhibiting signal transmission.

Finally, something as basic as power can affect an Ethernet installation. Office-grade Ethernet components may not function in an industrial environment powered by 24 or even 48 volts, with AC and DC sources. Industrial grade components will probably be required.

Protecting the cable

In a typical data center, you'll probably find a server with unshielded twisted-pair cables hanging from the back and running unprotected to the ceiling—and that is perfectly fine. In an industrial environment, however, cables need to be pro- tected with plastic or metal conduit. It is acceptable to run Ethernet along the ceiling in open trays, but when those cables reach the wall or anywhere they can be sprayed with water, get hot, or be hit by a lift truck, conduit should be used.

But conduit also has its limitations. Examples of where conduit is not appropriate are moving processes, such as robotic arms, or cameras for machine vision (process monitoring). In robotics, the Ethernet cable is run right up the robot arm and fastened to the outside of the housing. Both the robot arm and the cable must move, bend, and flex repeatedly, ruling out the use of conduit. Cable designed specifically for this Industrial Ethernet application is required.

EMI shielding is another consideration for Industrial Ethernet. For example, one machine might be filling bottles and another loading them into the boxes. The Ethernet line must be separated and shielded from the EMI field that machines, cables, motors, and transformers generate. Excessive elec- tronic noise will interfere with data signals. Interference usually manifests itself as particular types of easily recognizable network errors, and indicates that the transmitted frame has been corrupted somewhere along the path.

What can be done about it? UTP (unshielded twisted pair) cabling is, by nature, fairly immune to lower levels of EMI. An opposite signal is transmitted on each leg of pair, and because the pair is located in the same place, any interference is the same on both legs, effectively canceling out EMI. For higher levels of EMI often found in an industrial setting, use of shielded twisted pair (STP) can help improve transmission capability. For total immunity against EMI, fiber-optic cable can be used.

An IP (Index of Protection) rating indicates the degree of protection offered by cable and components. The rating is always specified with the letters IP, followed by two numbers. The first number indicates the degree of protection against solid foreign bodies. The second number is the degree of water protection. A lower rating of IP55, for example, indicates that a device provides enough protection from dust particles and water spray that operation won't be disrupted. A higher rating of IP67 indicates the device is dust-proof and can be immersed in water over time without adverse effects.

Using enhanced, higher-rated cabling is not the only means of dealing with harsh environments. Consider using a combination of separation, isolation, and enhancement strategies. For example, when there is a risk of liquids, separation can be achieved by running cabling in cable trays at ceiling height as opposed to on floor pathways. Isolation can be achieved by using appropriate conduits or raceway, such as properly grounded metal conduit that helps isolate some EMI noise.

When operating under harsher conditions, take preventative measures, such as regularly replacing patch cords and connectors well before their rated life to help avoid downtime. By establishing and documenting the baseline of your network and doing regularly scheduled preventative maintenance, you can keep your network running more reliably while also tracking down and correcting problems more quickly when they occur.

What to look for

Troubleshooting issues include:

• Poor cable terminations or cable faults—If a cable is sud- denly cut, the symptom may be that the system simply stops. Or, with faulty crossconnection through a junction, for example, you may get CRC (cyclic redundancy check) or FCS (frame check sequence) errors. These types of errors indicate incomplete signals being transmitted. The PLC (programmable logic controller) has detected corruption in a frame that contains critical information and throws the frame away. Now the PLC is still waiting for that information—the temperature of the glue for the labels on the bottles, for example—so, it asks again. If the re-transmission isn't successful because of the faulty cable, either the system aborts, or the line produces bottles without labels because the glue wasn't the correct temperature to adhere.

• Insufficient cable rating—In a heavy industrial environment (mining, for example), cable may be at risk from temperature extremes, water, or being run over. Without sufficient protection, the insulation might soak through, be cut, or short circuit. Standard office Ethernet cabling doesn't stand a chance under these conditions. Make sure both cabling and connectors have the appropriate IP ratings to withstand the particular hazards of your environment. In addition, use protective cabling in any areas with repetitive motion or an area that a link might be stepped on or crushed. Many cable manufacturers offer specific cabling with boots and/or advanced engineered material cable jackets specifically for harsh environments.

• Issue with connectors—The cable as well as all the components of a network on a manufacturing floor must be different from those used in office environments and data centers. In areas with extreme temperature swings, high humidity, or chemical or high-pressure washes, consider robust connectors and components like the M12. This popular 4-pin connector has a rubberized boot in diameters ranging from 6.0 to 6.7 mm. The M12 has been used for decades in industrial and production environments to transmit power and signals to optical sensors. In newer installations, it is also being used for bidirectional communications, such as Category 5e or 100 MHz. If you're using RJ-45, the IP67 rating is reached by using sealed connectors. It is also important to understand any external machinery noise issues when deciding between UTP (unshielded), STP (shielded) or fiber-optic components.

• Contaminated fiber-optic cable end faces—Fiber-optic connectors are microscopic and are particularly susceptible to contaminants. When light can't pass through, this causes reflectance. The signal is not fully transmitted and communication breaks down. One international transportation system, for example, discovered that fine dust from routine wear on the rubber train tires was clogging the fiber-optic communication cable. Trains were not reliably receiving information about whether another was on the track ahead, activating safety features that automatically stopped the trains. Unhappy commuters were kept waiting because of dust.

A real world example

Quabbin Wire & Cable Co., Inc. (www.quabbin.com) in Ware, MA manufactures a variety of thermoplastic shielded cables for use in a range of applications, including Indus- trial Ethernet. To fully serve this new market, Quabbin is introducing cable with multiple jacket options suited for diverse industrial environments. Each material provides different mechanical and electrical properties; for example, the environment in an automotive assembly line will be very different than in a petrochemical refinery, and the optimum cabling design will be different as well.

Industrial Ethernet requires you to think of a different set of parameters when selecting cable. Data transmission speed still matters, but the factors Quabbin considers for Industrial Ethernet cable goes well beyond speed. The primary concern is long life in continuous flex applications combined with resistance to petrochemicals, acids, bases, and hot welding splatter. Other concerns are tear, abrasion, and crush resistance, along with durability in ozone and ultraviolet light. All of these factors must be considered when selecting Industrial Ethernet cabling, or it may fail in the field.

According to Kevin Drummond, director of sales and marketing for Quabbin, The industrial world as it relates to Ethernet is full of trade-offs. The critical factor is elimination of downtime. Electrical performance is an important but secondary concern.

Drummond notes that most office patch cables are jacketed with PVC, which promotes good electrical performance on a data cable, but does not survive long in an industrial environment. Chemicals, temperature extremes, and continuous flexing quickly take their toll on a PVC jacket. In industrial applications, the lack of a rating or a slightly limited transmission distance may be acceptable because the selected jacket material is the only one able to survive in a particular chemical environment.

That's why it's so important to discuss with your customers the exact conditions of the environment that the cable will need to survive in, says Drummond. This is not a ‘one size fits all' game. Don't fall into the trap of using one type of cable everywhere. Take the time to know your application.

Extreme opportunities

Quabbin sees continued growth for Industrial Ethernet, meaning installation projects for new networks and upgrades from older, proprietary systems.

Even in troubled economic times, Industrial Ethernet will continue to expand and replace existing systems on the factory floor. Installers who follow industry guidelines and wish to transfer these practices to a new market oppor-tunity can do so, but will have to learn the physical requirements. For Indus- trial Ethernet, performance is important but uptime is even more essential. Protecting cable from the hazards of the industrial environment will help ensure success.

MARA WHITE is Fluke Networks' (www.flukenetworks.com) marketing manager for Industrial Ethernet.