By Al Feaster, DYMO Industrial

In the workshops I conduct on network infrastructure, I have the opportunity to talk to a lot of network installers about best practices in telecom network installation. When the topic turns to network cable identification, I have found that most installers are aware that an industry standard for cable labeling exists, but many confess that they do not follow it consistently in their daily work. The feedback I get from these professionals suggests they are slow to adopt the cable-identification standard because they don't understand it and as such, question its value. Hearing this gives me the opportunity to introduce some right thinking, and show them how embracing labeling standards is not only good practice, but also good business.

The Telecommunications Industry Association (TIA; www.tiaonline.org) 606-A standard, adopted in 2002, defines a labeling standard that maps a cable precisely to the floor, telecom room and patch panel position or block position on which it is terminated. The standard is not mandatory, though increasingly designers, end users and building owners are requiring and specifying the standard. It stands to reason; at roughly $200 per box, the cost of network cable has quadrupled in 20 years. Telecom networks are increasingly expensive to install and maintain, and building owners are reluctant to replace a plant or pay exorbitant amounts for maintenance and upgrades. Further, connectivity manufacturers have to certify that an installation has been done properly as part of their customer warranties.

Proper labeling is an integral part of the telecommunications infrastructure installation and testing process and is simply good network-investment management. The TIA-606-A standard sets a minimum level of information on the cable label so that it can be traced back to the specific floor, room and termination. Following this standard labeling scheme reduces the time required to identify and trace a cable when problems occur or when a move, add or change (MAC) is required. Following the standard also discourages proprietary labeling schemes that place meaningless information on patch panels and faceplates, which might confound future maintenance and upgrade efforts. The labeling scheme also provides continuity in large buildings and multi-building campus layouts, allowing owners flexibility in working with different contractors over the life of the network.

A non-labeled plant is difficult and costly to maintain. Installers at the workshops often tell me they turn down repair and maintenance bids because cable tracing is so labor-intensive and adds so much to the project overhead that they can't bid competitively. From the building owner's perspective, a non-labeled plant becomes a liability because they cannot get competent maintenance work done cost-effectively.

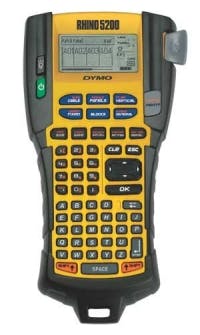

The Rhino 5200 labeling tool from DYMO includes the must-have features mentioned in this article, including hot keys and templates that are predesigned to work with patch panels from major manufacturers.

There is real evidence that adopting cable-labeling standards creates business opportunity for network installers. One contractor I know follows the TIA-606-A standard religiously, along with other best practices such as laying hook-and-loop strips every 6 to 8 inches under the access floor and bundling the cabling together. In essence, he puts his signature on his work. This professional's reputation for quality installations has garnered him a strong book of business. In fact, he's in such demand that he no longer has to seek bids. He picks and chooses projects.

In addition to embracing the 606-A standard, contractors can streamline the labeling process even further by working with the right labeling tool. The most important consideration is to use a tool that is designed specifically for the low-voltage industry. At a minimum, the labeling tool should have the following features.

Labels that adhere properly and last – which ensure that a good labeling job stays good, with no repeated effort and no confusion on future jobs due to labels that have fallen off the cable

Vertical wrap capability – which repeats the label code 360 degrees around the cable so it is easily identifiable and can be read from any angle; this reduces cable twists that can lead to cable damage or loose connections

Label spacing that can be calibrated to the proper dimensions of a patch panel, so you can easily line up identifiers under each port in a patch panel; this eliminates the guesswork in spacing, speeding up the job and reducing waste

Templates that are predesigned to work with major-manufacturer patch panels

Hot keys that are programmed with the label specifics for each job

In our workshops, we've demonstrated how the right labeling tool, coupled with a strong knowledge of the labeling standard, can cut a 45-minute patch-panel-labeling job to 5 minutes. In large installations with hundreds of patch panels, the time savings can be tremendous.

The bottom line is that proper labeling is a small investment that can pay substantial dividends for contractors, end users and building owners. The TIA-606-A standard is a rational labeling system based on solid fundamentals, which provides accuracy, clarity and continuity in a network scheme. End users and building owners should work the standard into their specifications. Contractors should facilitate more training to teach installation technicians how to use the labeling standards properly and use the most-efficient techniques. Increased adoption will provide investment protection for users/owners and competitive advantages for contractors—in short, an all-around win for the industry.

Al Feaster, RCDD is national account manager with DYMO Industrial (www.dymo.com/industrial).