December, 2012 Issue of Cabling Installation & Maintenance Magazine

Making sense of one of the most confusing and misunderstood phases of fiber-optic system installation.

By Clay Franklin and Mike Fuller, Corning Cable Systems

In the telecommunications industry today, testing is one of the most confusing and misunderstood phases of installing a fiber-optic system. While misunderstood, optical-fiber testing is one of the final and most important procedures in installing optical networks.

There are so many questions. Should I understand and comply with the new encircled flux standards? Is encircled flux compliance the responsibility of the installer or the test-equipment manufacturer? Should I be performing Tier-1 or Tier-2 testing? Should I use a two-jumper method (Method A) or a one-jumper method (Method B)? Answering these questions does require some research and education from all involved. Coming from an installer background, we prefer to use the KISS method as much as possible, which is to keep it simple. This article provides an overview of the industry standards for testing a fiber-optic system, some general recommendations and guidelines, and how the KISS method applies.

When you begin to consider optical testing, you must know where to begin looking for information. You can start with component and equipment manufacturers that follow industry-standard recommendations for manufacture of products used in fiber-optic systems. Standards from organizations such as the International Electrotechnical Commission (IEC) and the Telecommunications Industry Association (TIA) are used both in factories while manufacturing components and in the field where those components are installed. The standards organizations aim to create consistency and best practices for optimum system performance. The two standards reviewed in this article are TIA-526-14-B (multimode) and TIA-568-C.0, C.0 Addendum 2 and C.3, which provide testing recommendations and guidelines for fiber-optic testing.

Encircled flux multimode testing

Let’s start by discussing one of the industry’s most-debated topics. The future of testing multimode fiber is going to change with TIA’s adoption of IEC 61280-4-1, the encircled flux testing procedure. As transmission speeds have increased on multimode fibers from 1-Gbit/sec to 10-Gbits/sec and beyond, allowable loss budgets have decreased significantly, allowing little room for error.

Launch conditions during testing varied wildly and therefore created inconsistent test results that could potentially result in poor performance or failure of optical systems. Encircled flux launch conditions were created to produce much-needed consistency during this testing phase, which would more accurately predict capabilities of networks operating at these higher transmission speeds. Industry leaders agree that encircled flux is the most accurate method to test multimode fiber, as it controls the launch conditions coming from the optical sources.

Whether achieved outside the source through a conditioned jumper or by using an out-of-port solution (managed inside the source), the responsibility falls on the test equipment manufacturers to bring a reliable solution to market. Until very recently, conditioned jumpers were the sole means of achieving this launch and they were both costly and difficult to manage in the field. Test equipment manufacturers have now made it easier for the installers to achieve standards compliance by having an out-of-port solution. It is understood that the source, as supplied, has been verified by the test equipment manufacturer to produce the specified launch without the use of external jumpers. With this type of solution, the multitude of external mandrels or conditions will be a thing of the past, which will create one less thing an installer needs to do their job correctly. Keep it simple: Because test equipment that meets the encircled flux standard will provide the most consistent and accurate test results, installers should seek to update their test equipment when feasible to EF-compliant sources.

Standards overview

TIA-568 is the primary standard for field testing, and it answers most of the questions at hand. Unfortunately, most of us do not have a copy of this standard in our briefcases, let alone our toolboxes. Let’s start with the basics by identifying the three major factors (events) that introduce loss into a fiber-optic system: cabled fiber loss, connector loss and splice loss.

Within TIA-568, you will find that fiber loss will vary by fiber type and is measured in decibels (dBs) per kilometer (km). This fiber-type-specific loss value per kilometer is provided within the standard, but can also be found on cable data sheets shipped with cable from the manufacturer. In addition, you can go to most manufacturer websites to gather that information.

In contrast, TIA-568 is more prescriptive with connector and splice loss: 0.75 dBs per mated connector pair and 0.30 dBs per splice (mechanical or fusion). The table represents an example of how a system link loss budget can be calculated. These are the components needed to build a loss budget and can be acquired through knowledge of the system route diagrams. If neither is available, an optical time domain reflectometer (OTDR) can be used to get a signature trace of the fiber link. Keep in mind that events on an OTDR can be a misrepresentation of the real events and introduce user variability. For example, a bad mechanical splice could appear to be a connector pair.

With this understanding of events and their associated loss, we can explore the types of testing used in the fiber-optic industry. TIA-568 categorizes testing into Tier 1 and Tier 2. TIA-568-C.0 mandates Tier 1 testing to ensure system performance and integrity. The Tier 1 tests consist of link attenuation testing, link length and a polarity check. During the attenuation testing, each link is measured for attenuation with an optical loss test set (OLTS) or a light source and power meter (LSPM). This most accurately characterizes total system capability. Fiber length measurement can be achieved optically (OLTS or OTDR) or calculated by using cable sheath markings. Polarity is verified either with an OLTS/LSPM or a visible fault locator (VFL).

Optional but equally important Tier 2 testing is a supplement of Tier 1 testing with the addition of an OTDR trace of each fiber link. OTDRs provide in-depth signature traces (pictures) of fiber links, which show normal cable/fiber attenuation, insertion loss and reflection at the connectors, splice points, and unanticipated loss events, such as bends and breaks, for example. Tier 2 testing has traditionally been seen on longer-length outside-plant systems greater than 100 meters, which contain multiple loss events. OTDR traces are a great documentation tool for the end user, enabling them to see the quality of the installation while also serving as a potential reference for future troubleshooting.

The next standard to understand, TIA-526, takes a more comprehensive look into attenuation testing than TIA-568’s Tier 1 testing. Again, attenuation testing is the most misunderstood and error-filled area of fiber-optic system testing. TIA-526 characterizes referencing processes into three different procedures: one-jumper reference, two-jumper reference, and three-jumper reference. These were formerly known as Method B, Method A and Method C, respectively. The naming convention was updated in 2010 to make it easier for installers to understand how many jumpers should be used in the referencing procedures when testing.

One-jumper reference (Formerly Method B)

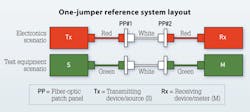

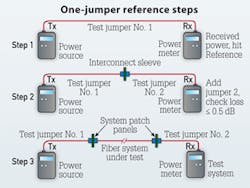

The one-jumper reference procedure is the most commonly used and preferred method in the industry today. Due to the old nomenclature, most installers err by using the two-jumper reference (Method A) as their standard procedure. Keep it simple: Use the one-jumper reference when the system under test is electronics to a patch panel to a fiber-optic cable to a patch panel to electronics (as shown in the figure titled “One-jumper reference system layout”).

Another scenario in which the one-jumper reference should be used is when the system under test does not have any available documentation, and an OTDR is not available to shoot a signature trace. The one-jumper reference is the TIA-preferred test method, as it does not introduce additional loss into the system, therefore ensuring that the test results show tip-to-tip results. The figure “One-jumper reference steps” details the procedure.

Two-jumper reference (Formerly Method A)

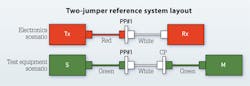

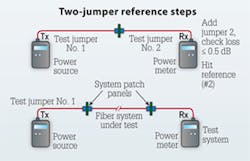

Many installers today improperly use the two-jumper referencing procedure on all systems due to the former Method A nomenclature and a general lack of understanding of testing fiber-optic systems. It is easy to understand why someone might believe it is appropriate to use a two-jumper reference when using two jumpers to test a system (one in the source and one in the meter).

This unfortunately is incorrect. Consider that if two connector pairs are needed to be tested within a system, then zero connector pairs should be referenced out. By using the two-jumper reference for these most common applications, a connector pair is improperly referenced out, providing false power readings that may impact short- and long-term performance of the system. Keep it simple: Reference out a connector pair by using a two-jumper reference when the system under test is electronics to a fiber-optic cable to a patch panel to a fiber-optic cable to electronics (as shown in the figure titled “Two-jumper reference system layout”).

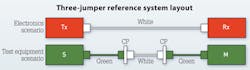

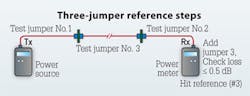

Three-jumper reference (Formerly Method C)

Unlike the other two referencing procedures, the three-jumper reference rarely is mistaken for another referencing method. Keep it simple: When the system under test is electronics to a fiber-optic cable to electronics (as shown in the figure titled “Three-jumper reference system layout”), use the three-jumper reference.

With the increased deployment of higher transmission speeds (40- and 100-Gbits/sec), MPO-style connectors are required. Therefore, this three-jumper reference procedure should be used to test MPO-to-MPO trunks. Also, when testing reference jumpers used in all three procedures, the three-jumper reference is the proper method for testing jumpers.

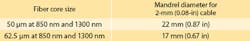

Multimode fiber mandrel wrapping

Now that the confusion over the three referencing procedures is cleared up, let’s discuss mandrel wrapping. Small-diameter mandrels on the launch reference jumper were and are many times used to remove higher-order modes that could negatively impact consistent test readings. This was a standards-based method prior to the newly adopted encircled flux standard. However, all mandrel wrapping requirements have been removed from TIA-526-14-B. If you choose to continue to use mandrels without the use of an encircled flux-compliant tester, the nearby table provides the proper size of mandrel to be used when testing the different types of multimode fiber. Keep it simple: If using mandrels today, ensure with the manufacturers of both your test equipment and reference jumper that proper-sized mandrels are used and/or required.

In addition, if using bend-insensitive 50-micron fiber in your multimode reference jumpers to test your system without the use of an encircled flux-compliant tester, contact the cable manufacturer regarding mandrel recommendations.

Troubleshooting fiber systems

While testing a fiber-optic system, what happens when a fiber link does not pass the link-loss budget? Standards do not provide any details and/or guidance on troubleshooting installation issues. Troubleshooting is most often aided by tribal knowledge and prior experience, which can save significant time and money. The leading cause of failure of fiber-optic systems today is still dirty connector endfaces. Over the last five years, the industry has benefitted from several new cleaning products and video-inspection systems enabling the installer to see images of the connectors under test or during the installation. Details on connector endface inspection can be found in TIA OFSTP-14B with pass-or-fail criteria. Keep it simple: Start with the obvious—check the cleanliness of your connector endface first.

Troubleshooting can be simplified through the use of basic information/tools, such as system route diagrams, cable sheath marks and the installation test results. Times like these are when the OTDR and VFL are the best tools an installer can have at their disposal.

Summing it all up

It is certainly ironic that testing is the most critical and most misunderstood component of installing optical-fiber systems. The introduction of the encircled flux standard is aimed at creating consistency, accuracy and simplicity of testing multimode fiber systems. Test equipment manufacturers are rapidly developing solutions to make field measurements more practical and reliable. You should look to move your testing procedures to encircled flux compliance when feasible. This will ensure the greatest longevity and reliability of your optical fiber systems.

Furthermore, proper understanding of the appropriate test methods and referencing procedures using reference jumpers meeting standard specifications will play a great role in testing accuracy for both legacy and future systems. In general, choose Tier 1 testing when possible. And when in doubt, use the one-jumper referencing method.

Also, remember that the industry standards are recommendations and guidelines. Contact your component or equipment supplier with questions. So the next time you need to test your optical-fiber system, remember these three words: Keep it simple. ::

Clay Franklin is program manager and MIKE FULLER is marketing manager with Corning Cable Systems (www.corning.com/cablesystems).