By Brian Teague, Sticklers Fiber Optic Cleaners

Since the first commercial installations in the 1970s, the deployment of fiber-optic communication technologies has risen at an astounding rate. Fiber-optic capabilities have become so pervasive and so enabling that this technology truly has become the heart of our modern digital age. Just like a human heart, reliability is not just a “nice to have” - it is essential. Networks are expected to work seamlessly the first time, every time, all the time. This will rarely be the case without proper cleaning. Dirty fiber will impact and degrade the performance of the network.

For the optical signal to transmit and be received with minimal signal loss, ferrule endfaces must be completely clean of contaminants. One of the most basic procedures for the maintenance of fiber-optic systems is to clean the fiber-optic connector endface. The cleaning processes widely used in the field have not kept pace with the demands of the technology. A study by HTI Martin Technical Research Survey of 89 network owners and contractors looked at network failures and found the following.

- 80 percent of network owners and 98 percent of network contractors have experienced fiber failures during the installation process.

- 82 percent of network owners and 92 percent of network contractors use isopropyl alcohol (IPA) as the cleaning agent.

- 12 percent of network owners and 30 percent of network contractors use compressed air for cleaning.

This huge proportion of people experiencing fiber failure is, in my mind, greatly due to a lack of understanding about fiber contamination. With a few simple steps and proper tools, dirty connectors and slow networks can be a thing of the past.

Dust contamination

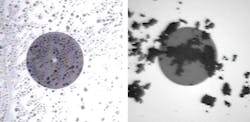

As a general category, contamination is a removable defect on the connector endface; lint, fingerprint oils, moisture and simple dust. Most commonly dust is the main “bad actor.” Dust is omnipresent, easily migrates and usually is not visible to the naked eye. Dust particles are opaque and cannot transmit light. Even as small as 5-6 microns (about one-tenth the size of a human hair), these microscopic particles will obstruct the signal transmitted along the fiber, just as the moon blocks the sun during a solar eclipse.

Dust can come from a variety of sources, many of which are not obvious. They include the following.

- Dead skin and hair

- Clothing

- Foam swabs and paper wipes, even “lint-free” wipes

- Zinc whiskers from electroplated surfaces

- Opening cardboard boxes and reams of paper

- Connector wear debris

- Dirty test assemblies and tools

- Protective end caps for connectors and adapters

- Electrical-generation pollution and vehicle emissions

- Plant pollen and molds

Because dust particles are so small, dust can be locked into place on and endface by an electrostatic charge. This can have a huge and deleterious effect on performance of the fiber. The electrostatic charge causes dust particles to migrate into the contact zone of the mated ferrule pair. The dust will cause signal degradation as the dust absorbs or reflects back into itself. Another issue is the creation of permanent defects on the ferrule surfaces in the form of scratches or pits.

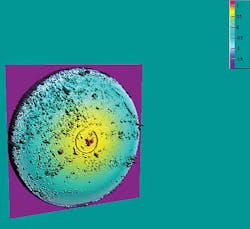

The risk of network impairment from contamination means the use of a ferrule scope is a good investment. It is important to select a ferrule scope that has good resolution with 200/400x magnification. The better-performing ferrule scopes come with automated inspection and analysis software that is set to the pass/fail standards in IEC 61300-3-35.

Electrostatic charge: Fiber’s worst enemy

Electrostatic charge is the invisible enemy. Any time there is contact friction - such as wiping an endface with a dry wipe - an electrostatic charge is generated. That electrostatic charge draws oppositely charged microscopic dust particles onto connector endfaces just like a magnet. Oppositely charged dust particles will electrically bond to the ferrule surface. These microscopic particles obstruct the signal path transmitted along the fiber, and is called insertion loss. In the MicroCare lab, we have documented this phenomenon in as little as 45 seconds after an attempted cleaning.

Electrostatic charges can come from any of the following activities.

- Dry wiping connectors with wipes that do not have static-dissipative properties

- Using certain types of foam cleaning sticks to clean and dry an endface (friction from non-conductive cleaning tools)

- Cleaning only with compressed air (the rapidly moving air creates friction that can impart an electrostatic charge onto nonconductive materials)

- Inserting or removing a connector into the adapter during mating (more friction)

- Removing the protective endcap from the connector or adapter (friction, again)

- Connecting to test equipment (a real friction addiction)

But because the components of a fiber connector are made of nonconductive materials - usually plastic, ceramics, glass and epoxies - the electrostatic charge does not have a dissipate; there is no path to ground. The charge will remain on the connector endface indefinitely and the particulate will remain locked in place until the endface is cleaned thoroughly and properly. Even if the central contact zone initially is clean, an electrostatic charge can cause dust to migrate from the outer regions of the ferrule toward the ferrule apex in the contact zone.

Refractive index issues

The most common effect of contamination on an endface is insertion loss; the light is blocked and the signal is lost. But the complete story is more complex.

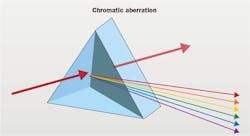

The burst of light that comprises the fiber-optic signal is made up of different wavelengths of light. If index of refraction within the fiber changes, that change will peel some of the wavelengths off and weaken the signal, which is called chromatic aberration. In the worst cases, it can change the refractive angle enough that the signal is lost completely. The higher the frequency of the light signal the greater the sensitivity to changes of the refractive angle. What can change the refractive index? The most common culprit is residue-based contamination on the connector endface. All of these microscopic troublemakers change the index of refraction.

There is still another problem with dust as well as liquid contamination. One dirty endface can contaminate another when they are mated together. If a dirty jumper - or power meter, or light source, or some other popular tool - is inserted into a clean connector both of them will become contaminated instantly. Network performance will suffer.

Wet or dry?

Traditional cleaning methods simply are not ideal to achieve contamination-free endfaces on modern, high-speed networks. Dry cleaning with a wipe or swab, as previously explained, will generate static and attract debris to the endface. It may also not be strong enough to lift some oils and grease from the endface.

Alcohol is sub-optimal as well. Many engineers use IPA to clean their fiber but all alcohol molecules are hygroscopic. IPA has a strong affinity for water, so it is always trying to pull water molecules out of the air and into the solution, especially with the pump bottles that many people use. That moisture can cause cross-contamination. It also will slow the drying process and it requires more air to evaporate the liquid off the endface. The extra air brings with it more dust and the risk of additional residues on the endface. (Although they are wonderfully convenient, presaturated wipes can contribute to contamination as the packaging over time degrades and residues leach into the wipes. So even when every effort is made to clean thoroughly, alcohol presaturated into cheap paper wipes could be the source of your dirty-fiber problem.)

The use of canned air may seem effective, but this method actually pushes dust around the ports and onto the endface, rather than removing it. Dry cleaning tools work, but they need to be used in combination with a wet-clean method.

Difficult-to-remove contamination like grease only can be eliminated with the use of a solvent.

In short, the most effective method of completely eliminating endface debris is wet-dry cleaning with the use of specially developed fiber cleaning fluids. Those fluids should be fast-drying, non-flammable, have a low surface tension and dissipate static. The fast-drying feature is especially important when cleaning fiber as there is not enough time for moisture to attract to the fluid, therefore stopping contamination. By using a specially designed fiber cleaning fluid and a lint-free wipe, the optimum results will be achieved.

Best practices for speedy networks

In conclusion, following are 11 simple steps to ensure contamination does not occur. If followed carefully, these steps will eliminate problems related to contaminated fiber.

- Wet-dry cleaning is most effective for removing all forms of contamination and eliminates electrostatic charge.

- Use optical-grade cleaning fluids that leave no residue and are fast-evaporating.

- Use cleaning fluids in hermetically sealed packaging to prevent cross-contamination. Refillable pump bottles are simply not up to the task.

- Use high-absorbency optical-grade fabric wipes (not paper).

- Always clean both ends of a connector pair, and do it just before mating.

- Clean new jumpers and patch cords, even right out of the bag, even if they have protective dust covers on them. You can be sure those jumpers weren’t properly cleaned in the factory, and the dust covers were not cleaned at all.

- When using stick cleaners, use one stick per endface to avoid cross-contamination.

- When using cleaning sticks, only rotate them in one direction; usually four to eight rotations is sufficient.

- Mechanical “push-to-clean” cleaners and cassette cleaners are good for light to medium levels of contamination.

- Boxes and tubs of optical-grade wipes plus a cleaning fluid are the best practices when splicing pigtails onto bulk cable.

- Clean tools give you the best results. Always clean test assemblies, power meters, light sources and all the other equipment and test gear.

Brian Teague is product manager for Sticklers Fiber Optic Cleaner products with MicroCare (www.sticklerscleaners.com).