Arlyn S. Powell, Jr.

Although firestopping is an important and straightforward activity, it is sometimes neglected and even omitted by cabling installers. "It`s the most ignored thing by installers that I`ve ever seen in my life," says Ed Phillips of Tel-Comm Contracting Inc. (Manchester, ME). "Every day, everywhere I go, I see violations of firewalls, firestops, fire floors and fire codes."

Phillips, who also chairs the standards committee of Bicsi (Tampa, FL), believes this neglect stems from ignorance. "Most installers don`t have any idea what a firewall, firestop or fire rating is," he says. "They take a screwdriver and poke a hole, shove a cable through, and leave it."

However, there is no excuse for this ignorance and the building-code violations that can result from it. Most firestopping, in fact, can be planned by referring to two basic documents -- the local building code and the Fire Resistance Directory published by the Underwriters Laboratories (UL -- Northbrook, IL). "The building code will tell you the level of performance required of the firestop system," states Bob Berhinig, UL associate managing engineer, "and publications like our Fire Resistance Directory will explain how to provide that level of performance.

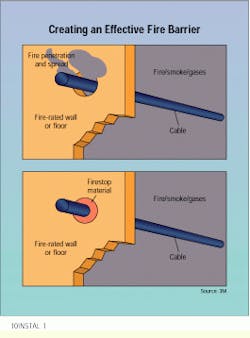

"The firestop assembly consists of three principal items: the fire-resistive wall or floor that`s being penetrated, the penetrating item, and the firestop material that goes around the penetrating item and fills the opening created by it," he adds.

Specifying fire ratings

The level of performance is specified in hours -- for example, a 2-, 3- or 4-hour firestop may be required. The hour rating refers to the amount of time it takes a fire to burn through the firestop under standard test conditions. In addition to the hour rating, there are two distinct types of fire-rating classifications. "An F rating indicates the period of time in which the system prohibits the passage of flames through the assembly," states Berhinig. "The T rating also has a limitation on flames, but there is an additional requirement on the temperature of the penetrating item."

During the standard fire-rating test, the temperature is measured on the penetrating item one inch from the floor or wall being penetrated. Both F and T ratings are derived from the same test, which is specified by a UL safety standard, UL-1479. This standard is approved by the American National Standards Institute (New York, NY), and its procedure must be followed and referenced by any testing laboratory -- whether UL or one of its competitors -- certifying firestop systems.

An alternative, according to Berhinig, is the E-814 standard of the American Society for Testing and Materials (Astm -- Philadelphia, PA). "The requirements in the UL and Astm standards are very similar," he adds.

To perform the UL-1479 fire-rating test, a section of wall or floor, complete with penetrating item and firestop system, must be constructed and placed in a furnace, where controlled fire and temperature conditions can be created. Wall and floor samples are normally 4 x 4 feet, says Berhinig, but when the penetration is made by several cable trays, the dimensions can increase to 14 x 17 feet for floors and 10 x 10 feet for walls.

The standard fire test consists of "a fire that reaches 1000F in 5 minutes, 1700F at the end of an hour and 2000F at the end of 4 hours," adds Berhinig. He stresses that the fire test is not only for penetrations of electrical and telecommunications cabling, but also for copper pipes, steel conduit, glass piping or any other material.

The results of these tests are included in UL`s Fire Resistance Directory. "We have a specific volume that`s wholly dedicated to firestop systems," says Berhinig, "and like everything else, it`s grown over the years." Now running 1100 to1200 pages, the directory is indexed by type of assembly (for example, wall or floor), type of construction materials used, type of penetrating items (cables, pipes and trays), and the fire ratings applied. "Even though it`s 1200 pages long, the way the systems are numbered simplifies the search," Berhinig adds.

The directory includes detailed drawings of wall and floor assemblies, along with penetrating items and fill materials. It indicates the sizes and dimensions of penetrations that are allowed, including minimums and maximums. It even provides information on the hardware, such as screws and fasteners, that can be used. "It doesn`t tell you how to construct it," Berhinig says, "but it does tell you the dimensions and other things that need to be understood by both the building inspector and the contractor."

In addition to describing tested firestopping assemblies, the directory lists all manufacturers of firestop products eligible to bear the UL mark. Berhinig believes that most of these manufacturers -- approximately 30 worldwide -- go out of their way to provide the contractor with accurate information about standards-compliant assemblies. This information sometimes includes computer disks and software that help the contractor specify the proper firestop system for a given fire rating. UL-classified firestop systems will, of course, bear the UL mark on all relevant materials.

Further Reading...

"Firestopping must move to the top of the installer`s checklist," August 1995

"Firestopping overnight cable access holes," December 1995

"Firestopping fiber-optic cable penetrations," November 1995

"Firestops: Part of doing business," October 1995

"Installing cable rack firestopping seals," October 1995

"Firestopping cable runs," May 1995

For More Information...

The basic reference for firestopping is the Fire Resistance Directory, published by Underwriters Laboratories (Northbrook, IL). This reference contains both standards-compliant firestopping procedures and a list of vendors of firestop systems. The Telecommunications Distribution Methods Manual from Bicsi (Tampa, FL), Chapter 8, "Firestopping," supplies basic information on designing firestop systems into cabling plants. Many manufacturers also provide useful information on the subject; Nelson Firestop Products (Tulsa, OK), for example, includes information on fire codes, firestop design considerations, specifying firestop systems, and testing standards, as well as company product information, in its Through-Penetration Firestop Technical Manual.

A firestop assembly consists of the fire-rated wall or floor; the penetrating item--cable, in this case--and the firestop material that goes around the cable and fills the opening.