Testing shows that cmp cables may be a better alternative to cmx and lszh cables in plenums.

Jim Hoover and Loren Caudill / DuPont

With associated local area networks (lans) growing at a dizzying pace, massive numbers of low-fire- performance communications cables are finding their way into concealed overhead and underfloor spaces of open-plan offices and posing a threat to firestopping systems worldwide. With the growth of networking has come heightened awareness among cabling contractors, designers, and installers that their firestopping efforts may be better served by installing high-fire-performance cables in plenum spaces otherwise intended only for noncombustible or limited- combustible construction materials.

Using plenums for building services is an increasingly common design alternative found in commercial buildings worldwide. Many new and refurbished buildings use plenums to hold communications cables, power cables, plumbing, fire detection and suppression systems, and similar mechanical and electrical services. Plenums offer convenient access, allow efficient alterations, lower construction costs, and improve energy conservation in heating, ventilating, and air-conditioning systems.

Revealing hidden spaces

Since plenum spaces are concealed, they can become unsafe havens for fire and smoke if combustibles are present. Numerous large, devastating fires have occurred in multistory buildings with combustibles in concealed areas.

Historically, products used in plenum areas had to be fire-partitioned and very low in fuel load and combustibility, or protected by either fire-resistant coverings or fire-extinguishing systems. These standards may have worked well in the past, but new fire-path and fuel-load problems are emerging--the number of personal computers on lans is growing at about 25% a year, and lan cabling systems are being replaced every two to three years.

Many spaces above ceilings and below floors once devoid of cabling are now filled with all types of communications cables, including low-fire-performance cables. Among them are cables known as low-smoke zero-halogen (lszh) in North America and as nonhalogen in Europe and Asia, as well as cmx (communications cable, dwellings), used in the United States, which must be installed in protective metallic conduit in plenums, and cmx/t (cmx installed in capped metal trunking), which is sometimes used in the United Kingdom.

lszh and cmx cables recently underwent a series of full-scale fire tests that simulated current installation practices in the United Kingdom. Also tested was cmp cable, a high-fire-performance communications cable (per nfpa 262, UL-910) used in the United States in plenum voids without requiring protective metallic conduits or trunking.

The United Kingdom`s Building Research Establishment/ Fire Research Station (bre/frs) conducted more than 50 fire tests on commercially obtained 4-pair unshielded twisted-pair (utp) communications cables, a type commonly installed in concealed horizontal spaces to connect PCs to lans. The 200 lengths of cable used in each test--each cable 7 meters long--represented about one generation of cable in a typical one-floor open-plan office layout, according to at&t site surveys. (More than one generation of installed cable is often present in many buildings.) Fire scenarios, ventilation conditions, and lan cable designs and configurations were varied. The comprehensive testing produced some dramatic and unexpected results about the firestopping ability of lszh and cmx versus cmp.

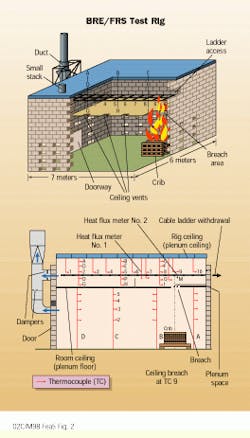

The test rig was a 7.4 x 5.7 x 4-meter-high concrete-block, burn-room/ceiling-void, re-burnable structure with a 2-hour fire-rated suspended ceiling forming a concealed above-ceiling open-plan space 1 meter deep. Cables were supported on a steel ladder 7.2 meters long and 0.38 meters wide, and the ladder was located midway between the suspended ceiling and the structural ceiling of the test rig.

To simulate an office-workstation conflagration, a 1-megawatt source fire was created with a 150-kilogram crib of kiln-dried pine. The air extraction system was capable of 4.5 cubic meters/second. Heat and smoke from the crib fire entered the plenum through a breach hole in the suspended ceiling directly over the crib and were extracted through vents at the far end of the plenum. Linear flow rates could be controlled at intervals of up to 10 meters/sec.

Measures of fire performance included mass loss, pressure differentials, lateral flame spread, heat flux, vertical temperature profiles, smoke opacity, heat release, carbon monoxide and carbon dioxide generation, and oxygen depletion. Tests were documented with still and video photography in both infrared and white light. Most data was logged electronically about every 10 sec for real-time online graphical monitoring, then stored in spreadsheet formats to facilitate statistical analysis and computer modeling.

Great balls of fire

During the testing, lszh and cmx cables ignited readily, released comparatively large amounts of heat, and burned the full length of the plenum. A large fireball developed on the horizontal cable ladder and a large pool of fire formed on the suspended ceiling beneath the cable ladder in the plenum space. lszh smoke density was higher than that of cmx/t and cmp but noticeably lower than cmx.

When exposed lszh cables burned, downstream peak temperatures along the entire length of the ladder exceeded 800oC, which can cause structural steel beams to deform severely, according to previous bre/frs tests. cmx downstream peak temperatures averaged about 775oC, while cmp temperatures were less than 335oC.

lszh contains high-fuel-load, flame-retardant polyolefins, while cmp is commonly insulated with low-fuel-load fluoropolymers such as Teflon. In related small-scale fire tests, flashover-type explosions occurred with some lszh materials, while cmp materials produced no explosions.

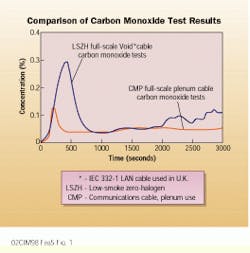

Along with preventing the spread of flame and heat generated by a fire, firestopping must restrict smoke and toxic combustion. The testing showed that lszh cables produced more smoke and carbon monoxide than expected, while cmp cables showed no signs of flame spread and generated very little smoke. When the smoke cleared, tests conclusively showed cmp cable to be superior to lszh and cmx cables in overall firestopping performance.

When devising and implementing firestopping systems, contractors, designers, and installers should consider using plenum cmp cabling that meets current U.S. codes.

Fire testing at the United Kingdom`s bre/frs showed that lszh cable produced noticeably more carbon monoxide than did cmp cable.

At the full-scale test rig, bre/frs conducted more than 50 fire tests on the firestopping ability of commercially obtained 4-pair utp plenum cables.

Source of the fire was a 150-kilogram crib of kiln-dried pine.

Inside the full-scale test rig, lszh cable (left sequence of photos) readily ignited and spread along the ladder, creating a large pool of fire on the suspended ceiling beneath the cable ladder in the burn-room`s plenum space. Conversely, when cmp cable (right sequence) was fire-tested under similar circumstances, flames did not spread along the ladder.

Jim Hoover is global regulatory manager and Loren Caudill is regulatory programs manager, both at DuPont (Wilmington, DE).