Limited-combustible cable makes for safer plenum spaces

Can data cable be as fire-safe as other building materials?

The unprecedented growth of LANs and client-server computing over the past 10 years has produced a dramatic increase in the amount of cabling used in buildings. As a result, concern has grown over that time about the accumulating fire loads found in air-return plenum spaces.

Approximately two-thirds of all commercial LAN cabling installed in the United States is plenum-rated. This cabling most often is installed in the air-return space above the suspended ceiling without the use of metal conduits. Frequently, these cables are abandoned in place when building residents reconfigure workstations or upgrade their networks. The accumulation of cables in plenum spaces can be overwhelming.

The accumulation of generations of unprotected cables in air-return plenum spaces has caught the attention of the National Building Code community, the National Fire Protection Association (NFPA), and two key groups within the NFPA: the 90A Hearing and Ventilating Group, and the 70 National Electrical Code Group.

An event that helped prompt the formation of fire-safety performance specifications for low-voltage wire and cable products was a fire that took place at the former World Trade Center in 1975. In this incident, an office was gutted by a fire that concentrated in the air-return plenum above the suspended ceiling.

The fire marshal's report of that fire included the following notes: "The worst and most hazardous condition is when wires and cables with combustible insulation are run through plenums to service the floor above. This provides a double hazard by introducing combustibles into the air conditioning.

"Telephone cables can carry more than messages. They can carry fire through a wall, even when conventional firestopping is provided. It should be noted that the mass of cables to supply communication equipment in many office occupancies is sufficient to sustain a substantial fire. While an individual cable is extremely difficult to ignite, a group of cables lying parallel will burn intensely ..."

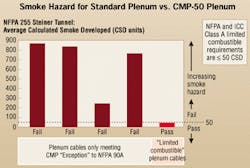

When the Underwriters Laboratories (UL) 910 fire safety test-now known as NFPA 262-was created for plenum cables in the 1970s, the pass/fail criteria were set at limits that were less demanding than those for other construction materials in air-return plenums. The pass/fail criteria for materials such as wallboard and ceiling tile, which are either used to manufacture these spaces or will be exposed to the air flow, is controlled by the NFPA 255 and NFPA 259 tests, which describe the testing requirements for limited-combustible materials. The pass/fail criteria for these tests are significantly more demanding with regard to smoke generation than the NFPA 262 test.

During the 1970s, low-voltage cable, for the most part, contributed only minimally to building fire loads. Personal computers and client-server computing had not yet arrived, and other than voice and signal wiring, the concentration of low-voltage wiring was far less significant than it is today.

But other high-profile fires during that decade-including fires at the MGM Grand Casino in Las Vegas and at a New York Telephone switching center-brought more attention to cabling as an agent of combustion. In light of these events, improvements were made in building-fire safety. The NFPA developed its 262 test, which is still used today to list plenum cable. At that time, NFPA code officials believed that specifications of the 262 test, though less stringent than those for other building materials, were appropriate. Other materials, including pneumatic tubing and speaker housings, are part of the NFPA's 90A and 70 codes, and are subject to less-severe testing than that specified in NFPA 255 and NFPA 259.

Problems and solutions

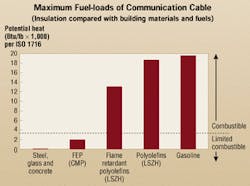

The advent of client-server computing and the development of the PC paved the way for the increased presence of LAN cabling in commercial buildings. Consequently, low-voltage cabling's contribution to a building's fire load has changed. In many new installations, such as data centers and Internet hotels, cable can present a larger fire load than that presented by wall coverings or furniture. Many authorities-having-jurisdiction (AHJ), such as building code officials, fire marshals, and electrical inspectors, have expressed concern regarding the fire-safety issues of today's cable-rich installations.

This increase in fire load presents hazards that concerned groups currently are addressing. AHJs have demanded that something be done about the building-fire-load increase caused by the accumulation of cable in air-return spaces.

In response to this request, cable manufacturers have introduced a plenum cable with higher fire-safety characteristics. The new classification is called "limited-combustible cable," and is identified by the listing mark CMP-50. UL and Intertek Testing Services (ITS)/ETL Semko both have programs in place to list this type of cable.

The creation of this higher-performance fire-rated cable does not eliminate CMP, OFNP, or other types of plenum-rated copper and fiber cable. This new classification is additive, and has been established to provide users with a more fire-safe option when selecting plenum cables.

NFPA 255 testing, sponsored by the NFPA's research arm-the National Fire Protection Research Foundation (NFPRF)-and a consortium of companies identified the difference in performance between different types of plenum-rated UTP cable constructions and a CMP-50 cable design. Not all plenum-cable constructions tested conformed to the NFPA 255 specifications, but all did pass the NFPA 262 plenum test. The primary difference between the tests is the significantly more-demanding pass/fail criteria for smoke emissions in the NFPA 255 test. As mentioned previously, these plenum cables are approved for use. The listing criterion that exists today for cables installed in air-return plenum spaces without conduit is the NFPA 262 plenum cable test.

The primary difference between traditional plenum cables and the limited-combustible cable is that the limited-combustible cable is insulated and jacketed with fluorinated ethylene propylene (FEP). FEP is used heavily in the LAN cable industry as a wire-insulating material. In the CMP-50 cable, FEP is used as the insulating material and also replaced flame-retardant PVC as the jacketing material.

A cable manufactured with 100% FEP passes the strict, limited-combustible criteria. With CMP-50 cables now available from a number of manufacturers, users and specifiers can opt for cable constructions that are as flame-retardant as wallboard and ceiling tile.

Building and safety codes

Both the NFPA Heating and Ventilating Group and the NEC Group are considering the adoption of CMP-50 cable into their codes. These codes specify fire-safety practices for the environments and systems for heating, ventilation, and electrical equipment. CMP-50 will not be included in the 2002 NEC, but is being considered for adoption in the NFPA 90A Code. CMP-50 cable will be considered for the next NEC cycle in 2005.

NFPA fire-safety codes and building codes are the foundation upon which building fire safety is determined. Fire-safety and building-structure codes have evolved dramatically over the past 50 years. Many landmark buildings have undergone, or currently are undergoing, renovation efforts to improve structural and fire safety.

These improvements were in evidence in the wake of the terrorist attacks on the Pentagon and the World Trade Center on September 11. Roger Lewis, a practicing architect and a professor of architecture at the University of Maryland, commented in the Washington Post after the attacks: "Historically, fire, not structural failure, is the greatest hazard in buildings. For two centuries, American codes have evolved and improved dramatically to protect buildings and their occupants from fire. The first line of defense is to minimize the chance of fire ever starting. If a fire starts, the second line of defense is to contain and suppress the flames and smoke while safely evacuating people.

"Codes require that buildings of certain sizes and types, especially those with high fire risks or high occupancies, be constructed of noncombustible materials such as concrete, masonry, gypsum, metal, and glass," Lewis continued. "To eliminate fuel for fires, codes further require that carpeting, furniture, and decorative trim be noncombustible or limited combustible and resistant to spreading flames."

CMP-50 cable, which is made of limited-combustible materials, will perform in a fire scenario similar to the wallboard and ceiling tile materials that Lewis referred to.

Education will be the key to determining who ultimately will be interested in CMP-50 cable. This process is underway, as interested parties and codes officials begin to educate the specifying and end-use communities. Several end-user organization types have expressed interest in limited-combustible cable. Hospitals, elderly-care facilities, casinos, theme parks, and schools have life-safety concerns that CMP-50 cable addresses. Additionally, data centers, collocated switching centers, Internet hotels, banks, and brokerage houses have interest in CMP-50 cable because of the capital-investment protection that it offers.

The United States has led the developed world in the improvement of fire-safety materials and manufactured products. The development of CMP-50 cable is a natural progression in the ongoing effort to ensure that emerging fire-safety concerns are addressed.

Daniel Kennefick is copper-products business manager for Berk-Tek (www.berk-tek.com).