The potential for damaging electrostatic discharge requires preventive action.

Electrostatic charges and electrostatic discharge (ESD) are common natural phenomena that impact us in many ways. Walking across a carpet can generate several thousand volts of charge on a person-volts that will discharge when the person touches any other conducting object. The doorknob or elevator button is the usual victim. Regardless, we love our comfortable shoes, our carpets, and our soft padded chairs, and that is not likely to change anytime soon.

Microelectronic equipment has always been another potential victim, and standards for testing equipment sensitivity and reliability are not new. So what is new? Now, with higher levels of microelectronic integration and perhaps a little complacency, ESD seems to have caused incidences of equipment failure.

With an industry that, over the last few years, has done an excellent job of ensuring ESD protection, it has become easy for designers, installers, and customers to forget about ESD. Some people have even grown fond of that little doorknob wake-up every now and then.

Fortunately, recent incidences have not racked up enormous damage, although the frequency of incidents appears to be on the rise. So now that customers are migrating to new, super-speed communications equipment, and the service provided by this equipment is becoming increasingly mission-critical, it is time once again to make sure that everyone takes ESD seriously.

Essentially, electrostatic charges are generated when different materials come into contact with each other, and then are separated. When materials come into contact, a chemical bond of variable strength is formed between the two materials. The chemical bond involves a migration of electrons from one material to the other. When the bond is broken, some of the electrons may be left behind and result in an excess negative or excess positive charge on the materials. This charging effect, caused by contact, is made even greater by friction, such as rubbing the two materials together.

The amount of charge generated can be significant-in many cases, tens of thousands of volts. Just find a good conducting path that allows this charge to dissipate rapidly, and you have ESD. "Rapidly" is the key word here. A slow discharge is one of the more useful ESD protection methods.

Effect on cabling and equipment

Any user-installers, administrators, or end users-who touches equipment or cabling becomes a potential source of ESD into communications equipment. The international standard IEC/EN 61000-4-2 specifies test levels and procedures for manufacturers to verify equipment immunity to such events. It also includes guidelines for the manufacturer to specify for the installation and handling of equipment.

Another, more subtle source of ESD is charged cabling. The standards promulgated by the IEEE 802.3 committee identify this problem, but do not provide any guidance or testing methods for manufacturers. Generally, users become a source of ESD to the cabling (which, of course, is completely immune to ESD), and the charged cabling then becomes a source of ESD to the communications equipment. There have also been reports of cables developing their own charge from installation, from moving air, or from occupants walking over floor ducts. If the cables are not connected to an earth ground, electrostatic charges can remain for a long time, especially in dry conditions.

Precautions to prevent damage

The IEEE has warned about the effects of ESD on equipment since 1990, when it incorporated guidelines in 802.3i-1990 Twisted-Pair MAU and Baseband Medium, Type 10Base-T. The same guidelines continue to be incorporated in subsequent applications, including 802.3u-1995, Type 100Base-T; 802.3x-1997; 802.3y-1997 (100Base-T2); and 802.3ab-1999, Type 1000Base-T.

The following is a direct quote from section 14.7.2 of the 10Base-T document:

14.7.2 Network Safety (2) Static charge buildup on LAN cables and components. Such electrical safety hazards must be avoided or appropriately protected against for proper network installation and performance. In addition to provisions for proper handling of these conditions in an operational system, special measures must be taken to ensure that the intended safety features are not negated during installation of a new network or during modification or maintenance of an existing network.

With properly designed equipment, and good installation practices, the number of ESD problems that have been reported over the past 10 years are minimal. Although these guidelines are written for the manufacturer, the intent is for them to be incorporated into the manufacturer's product documentation as well.

Cat 6 worse than Cat 5?

Recently, some have argued that new Category 6 cabling generates worse ESD than older Category 5 cabling. The retention of charge and the discharge of cables is a function of cable design, cable materials, humidity, and installation practices. A cable's capacitance to ground determines how much charge a cable will hold. Once a cable is charged, its capacitance to ground and the relative humidity typically determine how quickly the charge will dissipate.

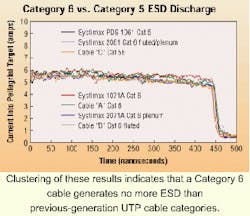

A series of experiments were conducted at Avaya Labs (Holmdel, NJ; www.avaya.com) to determine the charge-retention properties and ESD of different types of Category 5 and Category 6 cables. Essentially, the conclusion was that there is no significant difference between cable types tested.

A human body model ESD generator-the kind described in IEC 61000-4-2-was used to inject an 8-kV contact- discharge pulse into one end of a conductor pair of an assortment of Category 5 and Category 6 unshielded twisted-pair cables, each about 56 meters in length. After charging, a cable discharge waveform was then measured into a high-speed waveform recorder. These discharges were recorded as a function of the time interval between the charging and the discharging of the conductor pair, so a charge-retention profile was also recorded for each cable. To ensure repeatability and a fair comparison, each cable was laid directly on a ground plane for its entire length. This set-up also maximizes the cable's capacitance to ground.

Throughout the testing, it was readily apparent that humidity level was a significant factor in the charge-retention properties for all cables. After correcting for the effects of changes in the relative humidity, a comparison of these time-dependent discharge profiles shows little difference in the charge-retention and discharge properties of different cables.

The measurements were performed in a laboratory that had temperature control, but not humidity control. The relative humidity, however, was monitored along with the temperature and barometric pressure, so that measurements could be considered valid only when these values were within the ESD-standard-specified test range. This testing method provided a repeatable charging and discharging event that was immune to humidity changes. But the humidity significantly affected the dissipation of the charge on the cable over time. An equipment-based ESD standard is now being proposed. It calls for the creation of a cable discharge model to simulate cables being discharged up to 500 V, and then discharged into equipment. The proposed specifications would require equipment to withstand cable discharge events and return to normal function.

Cabling guidelines for ESD

Meanwhile, Avaya offers the following guidelines to avoid ESD problems.

- Examine the equipment manufacturer's specification sheet. Look for the test level of ESD immunity provided for, in accordance with the IEC/EN 61000-4-2 standard. If you cannot find an immunity section in the manufacturer's specification sheet, inquire about ESD performance or compliance with the requirements of the 61000-4-2 standard.

- Heed all of the equipment manufacturer's warnings to be certain that the equipment is installed and used according to specifications and guidelines.

- Assess your site's susceptibility to ESD. Low humidity and static-generating building materials are the primary cause of ESD phenomena. Mitigation techniques, such as anti-static flooring and humidity control, are important for critical installations.

Bryan S. Moffitt is a distinguished member of the technical staff in Avaya Labs' Systimax research and development department, Holmdel, NJ; Masood Shariff is technical manager in Avaya Labs' Systimax structured cabling system department in Holmdel, NJ; Tom Fritz, who recently retired from Avaya, also contributed to this article.

null