By Sterling Vaden, Surtec Industries

The newly published ANSI/TIA-568-C.2-1 Category 8 cabling standard specifies a 30-meter channel using the familiar four-pair twisted-pair cable construction and 8-contact modular RJ-45-style connectors. The channel configuration is similar to the 100-meter channel configurations of TIA 568-C.2 but it removes two connection points within the channel, providing for a total of only two. This is the so-called “interconnect” channel configuration, with one connector, a patch panel or outlet at one end, and one connector, an outlet or panel, at the other end. This configuration is ideal for data center configurations such as top of rack and end of row. This should not be a practical restriction on structured cabling installations, as few are thought to take advantage of the “consolidation point” at one end or need the extra patch panel for a crossconnect at the other. Indeed, both of these three-connector or four-connector topologies yield problematic configurations in terms of cable terminations, which could require modular plugs to be fitted to solid-conductor horizontal cables.

When cabling system manufacturers need to set up reference configurations to qualify channels to performance requirements, they must include a consolidation point in the four-connector channel for worst-case testing. The consolidation point has historically been a difficult part to obtain, even for factory channel test configurations.

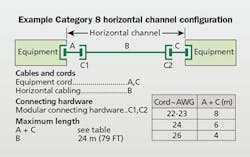

The Category 8 channel topology consists of two modular connectors*, 24-meter maximum length of horizontal cable, and 6 meters total modular equipment cords whose lengths may be divided as desired at each end of the channel. (*For international specifications, Class II cabling specifies the option of two types of non-RJ-45 shielded connectors.) There is no minimum length requirement for equipment cords, although the “worst case” modeling configurations for the standard used 0.5-meter cords as a minimum length at each end.

The reason behind the new channel configuration for Category 8 cabling is that the frequency bandwidth has been increased to 4 times that of Category 6A cabling, from a maximum frequency of 500 MHz to a new maximum frequency of 2000 MHz. In order to utilize this very wide frequency bandwidth, the insertion loss, crosstalk and return loss had to be greatly improved. Unfortunately, the maximum wire gauge for category cabling is set at 22 AWG and this limits what can be done to improve the insertion loss of the horizontal cable. In fact, even with 22-AWG conductors, the overall diameter of the cable and the flexibility of the cable have reached a practical limit of 9-mm or 0.354-inch diameter. This means that the only real option to improve the cable insertion loss was to reduce the overall length.

The other major performance factor that needed to be considered was alien crosstalk. At high frequencies especially, the alien crosstalk in unshielded twisted-pair (UTP) systems was found to be too high to support the 40GBase-T data transmission protocol. In order to achieve adequate alien-crosstalk performance, a shielded cabling system had to be specified. This could take the form of simply an overall shield over the four pairs of each cable (F/UTP), or individually shielded pairs with the option of an overall additional shield (F/FTP or S/FTP). For practical purposes, expect that the majority of Category 8 cables will have individually shielded pairs. This raised some issues related to cable balance requirements and also potentially with cable plenum fire-rating qualifications in the United States, as the majority of S/FTP cables are sold in the international market, where low-smoke zero halogen (LSZH or LS0H) are the governing safety requirements.

Applications

The Category 8 cabling system was designed primarily to support the IEEE 802.3bq 40GBase-T standard, which has just published. In simple terms, we can think of this data transmission standard as the IEEE 802.3an 10GBase-T standard run four times faster. The required transmitter bandwidth of 10GBase-T was 400 MHz (with 25 percent added for practical anti-aliasing filters to 500 MHz) and so the 40GBase-T bandwidth is 1600 MHz (again with 25 percent added) that yields a 2000-MHz bandwidth requirement for cabling specifications. From this point, the channel requirements were primarily driven by compromise between what the cabling system could provide and what the PHY transceiver could mitigate with sophisticated error-correction protocols.

The cabling system performance is limited by insertion loss, return loss, and crosstalk performance, and the two factors of crosstalk and return loss are typically dominated by connector performance. Fortunately the PHY can be designed to compensate for crosstalk and return loss, as long as the return loss doesn’t exceed a maximum threshold. As it turns out, both of these factors of crosstalk and return loss would prove to be significant design challenges for connector and cable manufacturers. While the cable crosstalk could be improved greatly with the use of individually shielded pairs, the return loss improvement proved to be a challenge at high frequencies between 1.25 GHz and 2.00 GHz. The cable crosstalk can typically manifest itself as an insertion loss “suckout” at some high frequency. The challenge for cable manufacturers was to move this “suckout” beyond the highest frequency needed by the application.

The PHY also has difficulty compensating for alien crosstalk, as was shown during the development of 10GBase-T. For 10GBase-T, the alien crosstalk coupling from all adjacent cables into any single pair had to be below 60 dB at 100 MHz. For 40GBase-T, the alien crosstalk was reduced to 75 dB at 100 MHz and 65.5 dB at 2000 MHz. This was a very significant improvement and drove the move to shielded cabling.

The internal near-end crosstalk (NEXT) of the channel is dominated by the connector performance at high frequencies, and the new Category 8 specifications were largely driven by mathematical modeling of connector performance. The specifications were determined from models extrapolated from Category 6A performance figures. The basic modular plug design was kept for backward compatibility, and the mated performance of plug and jack was calculated using the methods and techniques of Category 6A, optimized and refined for the much wider bandwidth. When it comes to real world manufacturing, compliance with the new performance metrics has proven to be a daunting challenge. Fortunately, the PHY can cancel internal crosstalk couplings to a satisfactory level.

Channel return loss has also proven to be a significant challenge. Connector design is a delicate balance between crosstalk compensation and return loss performance. The ability to maintain a 100Ω characteristic impedance throughout the system is a challenge at high frequencies even without the added challenge of crosstalk compensation between pairs. Impedance fluctuations must be minimized even for short lengths of transmission line within connectors. New methods of modeling these design variables would need to be employed to keep things under control. This design goal has proven to be a major challenge for both cable and connector designers. For cable manufacturers, existing designs may exhibit return-loss “spikes” in the region about 1 GHz (1000 MHz). In the European markets, some cable manufacturers were initially reluctant to specify cable performance beyond 1.6 GHz. This required improvements to design as well as manufacturing controls.

The direct attach channel

An interesting new feature of the Category 8 standard is the specification of a “direct attach channel.” This is a channel topology where there are no connectors within the channel and modular plugs at the ends of the channel are included in the performance specification. Normally, the standard channel definition does not include the plugs at the end of the channel that attach to the equipment. The normal channel performance specification begins with the cable. In the lab, this channel performance can be measured directly by cutting the plugs off and connecting the bare wire ends directly to the test equipment. In the field, permanent link performance is commonly measured. When channels are measured, the channel performance is calculated by time-blocking out the performance of the mated connection at the field tester.

The new direct attach channel needed a method of capturing the performance of the modular plug at each end, which could be field-installed. There are now field-installable modular plugs available that will maintain Category 6A and Category 8 mated connector performance. The solution was to use the patch cord test methods and measure the mated connector performance as part of the direct attach channel. This requires a Category 8-compliant test head that replaces the channel adapter in the field.

A similar device is also used with laboratory test equipment. This procedure was adapted from the modular cord or “patch cord” test procedure. The modular equipment cord NEXT loss and return loss procedures were applied to the direct attach channel requirements. The differences are that the direct attach channel is limited to 5 meters total length. The direct attach channel also must meet additional requirements for insertion loss, PSNEXT loss, ACRF, PSACRF, propagation delay and propagation delay skew. Other parameters, such as DC loop resistance, balance (LCL, ELTCTL), and alien crosstalk requirements are not specified for the direct attach channel but are covered by use of compliant cables. The direct attach channel may be constructed with solid conductor horizontal cables or stranded conductor cord cables, and the requirements are adjusted to compensate for the insertion loss of the type of cable used.

The specification of the direct attach channel has also led to development projects for “end-to-end link” performance specifications in other standards. The industrial cabling committees have long requested a method by which the performance of a channel including field-installed plugs could be verified. Projects are underway in TIA, IEC and ISO working groups. These specifications will, however, allow the use of additional connectors within the channel, and this complicates the specifications considerably.

PoE considerations

One interesting side benefit of Category 8 cabling is the much higher current capacity of larger cable conductors, coupled with improved heat dissipation characteristics of shielded cable design. This yields larger allowable bundle sizes for the same current capacity as lower categories of cable. For example, in the table, maximum bundle sizes are calculated for three different current levels. These bundle sizes are calculated assuming worst-case bundling and a maximum ambient temperature of 45 degrees Celsius. The temperature is allowed to increase up to the cable temperature rating of 60 degrees Celsius, a 15-degree rise. This is a reasonable maximum temperature rise assumption for adequate efficiency.

Note that the Category 8 rated cables allowed bundle sizes are several times those of even Category 6A rated cables. Even the worst-case Category 8 cable bundles carrying 1A per pair (approximately 100W per cable), the bundle size allowed is 126 cables in conduit, which is twice the Category 6A allowance. This essentially means that Category 8 cabling can be installed to support 100W PoE++ applications without worry about maximum bundle size.

Sterling Vaden is vice president of advanced technology for Surtec Industries (www.surtec.com.tw). He serves as vice chair of the TIA’s TR-42.7 Subcommittee and as editor of the following TIA specifications: ANSI/TIA-568-C.2-1 (Category 8), ANSI/TIA-1183, ANSI/TIA-1183-1, TIA-1183-A (draft), TIA TSB-5021 (draft), TIA-568-2.D (draft).