Optical-fiber manufacturing requires special processes and controlled quality.

Peter Dowling, SpecTran Communication Fiber Technologies Inc.

By now, many cable installers, engineers, and network managers have observed firsthand the performance characteristics of fiber-optic cable in its two main product categories--singlemode and multimode fiber. They`ve learned that singlemode fiber often excels at providing error-free transmission over long distances, while multimode fiber`s ease of handling and connectorization make it a popular choice in the fast-growing market for local-area and wide-area networks (lans/wans).

While this experience has taken some of the mystery out of fiber optics, the user community may still have a few questions about the actual composition of the fiber inside the cable. Some facts about how optical fiber is manufactured may foster better understanding of this light-carrying communications medium.

While manufacturing optical fiber is a precise, highly technical, and specialized process, both singlemode and multimode fiber are actually composed of two concentric glass structures--the core, which carries the light signals, and the cladding, which traps the light in the core.

Singlemode fiber is the preferred choice for long-distance communications because it allows information to be transmitted at high rates over distances of many miles without a repeater. A small core--a mere 9 microns in diameter--makes this transmission capacity possible. This core size limits the transmitted light in the fiber to one principal mode, which minimizes distortion of light pulses, increasing the distance the signal can be sent.

Multimode fiber is used today primarily for data-communications applications such as lans and wans in campuses, hospitals, and corporations. Its core diameter is large compared to the wavelength of the transmitted light. Therefore, multimode fiber propagates more than one mode of light--each light pulse travels down multiple paths. With its relatively large core, multimode fiber is easier to connect and splice. This makes it a popular choice for shorter-distance applications of numerous connections.

Three-step process

To convert raw materials into optical fiber, three main steps must take place: manufacturing the pure glass preform; drawing the preform; and test and measurement.

The first step in manufacturing glass optical fiber is to make a solid glass rod, known as a preform. Ultra-pure chemicals--primarily silicon tetrachloride (SiCl4) and germanium tetrachloride (GeCl4)--are converted into glass during preform manufacturing. These chemicals are used in varying proportions to fabricate the core regions for different types of preforms.

The cores of all standard communications fibers usually are primarily silica, with varying amounts of germania added to increase the fiber`s refractive index to the desired level. Singlemode fibers typically include only small amounts of germania and have a uniform composition within the core. Multimode fibers usually have a much higher refractive index and therefore, require much higher germania content. Also, the core composition and refractive index of multimode fibers may change across the core of the fiber to give the refractive index a parabolic shape. Because the refractive index changes across a cross section of the core, these multimode products are called graded-index fibers.

Several methods are used to manufacture preforms. SpecTran uses the modified chemical vapor deposition (mcvd) process, in which a highly controlled mixture of chemicals is carried to the inside of a rotating glass tube made of pure synthetic silicon dioxide (SiO2).

The pure silica tube is mounted on a lathe equipped with a special heat torch. As the gases flow inside the tube, they react to the heat by forming solid submicron particles, called soot, which is deposited on the inner wall of the tube. As the burner traverses the area where the soot is deposited, the heat transforms these solid white particles into pure, transparent glass in a process called vitrification. The material deposited in the tube will form the core region of the optical-fiber.

The process is repeated for many hours to lay down subsequent core layers. For every sweep of the burner, the manufacturer can modify the composition, viscosity, and thickness of the deposited layer to produce specific fiber designs. This, in conjunction with the ability to change the speed at which the burner moves and the temperature of the flame, provides the ability to manufacture a wide range of ultra-pure optical-fiber types.

The precise delivery of chemicals is ensured by using equipment that performs accurately and consistently. For example, mass-flow controllers are used to meter chemicals for the reaction. At SpecTran all critical process parameters are monitored and controlled in real time by online computers that are also programmed to collect pertinent process data.

After the desired amount of core material is deposited, the chemical flow is shut off, the speed of the torch is decreased, and the temperature of the flame is increased so the tube collapses into a solid rod. At the end of this process, an operator separates the preform from the rest of the glass assembly and moves it to the next step. The entire preform manufacturing process is highly automated and requires minimal human involvement.

The refractive index of the manufactured preform is now measured using a preform analyzer. This instrument compares critical core parameters to internal specifications and plots pertinent parameters automatically on statistical control charts that operators review for every measurement.

The pure silica glass starting tube has become part of the cladding region of the preform. The cladding is built up further by a process called "sleeving" or "overcollapse." Here, another pure silica tube is collapsed on the outside of the original preform, bringing the geometrical dimensions of the preform to final specifications.

Drawing power

The next step in mcvd optical-fiber production is to convert the manufactured preform into a hair-thin fiber. This is done in an operation called fiber draw. The tip of the preform is first lowered into a high-purity graphite furnace. Pure gases are injected into the furnace to provide a clean and conductive atmosphere. In the furnace, tightly controlled temperatures approaching 1900oC soften the tip of the preform. Once the tip is soft, gravity pulls a molten glob until it has been stretched into a thin strand.

The operator threads this strand through a series of coating dies, and the drawing process begins. The fiber is pulled by a tractor belt at the bottom of the draw tower, and then wound on winding drums. During the draw, the preform is heated to the optimum temperature to achieve an ideal drawing tension. Draw speeds of 10 to 20 meters per second are not uncommon in the industry.

During the draw process, the diameter of the fiber is controlled to 125 microns within a tolerance of 1 micron. A laser-based gauge is used to monitor fiber diameter. The gauge can sample the diameter of the fiber at rates over 750 times per second. The actual value of the diameter is compared to the 125-micron target, and slight deviations from the target are converted to changes in draw speed and fed to the tractor mechanism for correction. If the diameter of the fiber increases above target, the drawing speed is increased; if the fiber diameter starts falling below target, the draw speed is decreased.

A two-layer protective coating is then applied to the fiber--a soft inner coating and a hard outer coating. This two-part protective jacket provides mechanical protection for handling, while also protecting the pristine surface of the fiber from harsh environments. These coatings are cured by ultraviolet lamps. The drawing process is well-automated and requires virtually no operator interaction after the threading step.

Test and measurement

The drawn fiber is then moved to the test and measurement department, where all optical and geometrical parameters are checked to ensure that they meet stringent requirements. There are three main types of tests performed at this point: mechanical, optical, and geometrical.

First, the tensile strength of the fiber is measured. Each spool of drawn fiber is wound through a series of capstans and subjected to loads to ensure that the fiber has a minimum tensile strength of 100,000 pounds per square inch. The fiber is then spooled onto shipping reels and cut to specified lengths.

The optical fiber is also tested for point defects with an optical time-domain reflectometer, which uses scattered light to indicate the location of any anomalies along the length of the fiber.

A series of optical parameters is measured at several different wavelengths. These parameters include the following:

-attenuation--decrease in signal strength over distance,

-bandwidth--information-carrying capacity, an important measurement for multimode fiber,

-numerical aperture--the measurement of the light acceptance angle of a fiber,

-cut-off wavelength--in singlemode fiber, the wavelength above which only a single mode propagates,

-mode field diameter--in singlemode fiber, the radial width of the light pulse in the fiber; important for interconnecting,

-chromatic dispersion--the spreading of pulses of light due to rays of different wavelengths traveling at different speeds through the core, a limiting factor for the information-carrying capacity of singlemode fiber.

In addition, both multimode and singlemode fibers are measured for geometrical parameters, including cladding diameter, cladding noncircularity, coating outer diameter, coating outer noncircularity, coating concentricity error, core-clad concentricity error, core noncircularity, and core diameter.

Manufacturers have developed systems to ensure that the calibration of test equipment is benchmarked to industry standards and continually maintained. Periodic round-robin measurements are performed with customers and other fiber manufacturers to ensure accuracy, consistency, and repeatability of every test procedure.

Environmental and mechanical testing is also performed periodically to ensure that the fiber maintains its optical and mechanical integrity and complies with customer requirements. These tests include coating strip force, operating temperature range, temperature dependence of attenuation, temperature-humidity cycling, accelerated aging, and water immersion.

Highly technical manufacturing processes and advanced quality systems have resulted in the steadily enhanced performance of optical-fiber products. SpecTran and other U.S. optical-fiber manufacturers combine tight process controls with critical optical and geometrical measurements to ensure fiber that is very consistent--not only along the length of a particular spool, but also from spool to spool. The testing methods for obtaining this consistency are published by the Telecommunications Industry Association (Arlington, VA), which works with industry leaders to define U.S. optical-fiber standards.

As innovations in new fiber designs and processes continue to be made, manufacturers will be able to provide the cabling installer with even more reliable products for future communications applications.

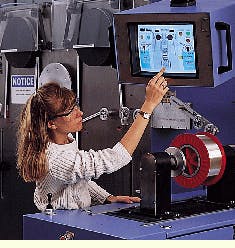

Quality is controlled with high-speed proof testing that uses touch-screen controls to ensure that optical fiber meets the industry`s stringent requirements.

In the modified chemical vapor deposition fiber-manufacturing process, a series of chemical reactions transforms a mixture of gases into a solid glass rod called a preform.

Fiber draw: The tip of the solid glass rod--the preform--is heated in a furnace until a molten glob "free falls" and is transformed into a thin strand of fiber.

Peter Dowling is the manufacturing manager for SpecTran Communication Fiber Technologies Inc. (Sturbridge, MA), which manufactures a complete line of multimode and singlemode optical fibers.