Put optical theory into practice for optimal network performance.

by Valerie Maguire, Siemon

In last month’s issue I provided information on fundamentals of optical light sources and transmission. In this continuation of that discussion, I will present information on the means by which that optical theory is put into practice by professionals in the networking and cabling industries.

Unlike balanced twisted-pair media, optical fiber cabling can be considered application-dependent media. This means that considerations such as distance, application and equipment cost play a role in the media selection process.

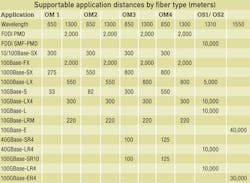

The Telecommunications Industry Association (TIA; www.tiaonline.org) and the International Organization for Standardization (ISO; www.iso.org), through reference to specifications from the International Electrotechnical Commission (IEC; www.iec.ch) and the International Telecommunication Union (ITU-T; www.itu.int), recognize six grades of multimode and singlemode optical fiber as shown in the table on page 12. Physical dimensions related to the optical fiber, e.g. diameter, non-circularity and mechanical requirements, as well as optical specifications such as attenuation and bandwidth are specified. It is important to keep in mind that these specifications are for the “raw” optical fiber before it is subjected to the cabling process. TIA and ISO use these optical fiber requirements to then specify requirements for OM1, OM2, OM3, OM4, OS1 and OS2 optical fiber cables and cabling.

While media selection may seem onerous, comparing the throughput and distance needs in your target environment against performance parameters is a good way to initiate the selection process. Although such comparisons may lead to the conclusion that singlemode fiber is the optimum medium under all scenarios, there are tradeoffs to consider related to the cost of optoelectronics and application implementation.

The XLR8 tool from Siemon combines splice activation and mechanical crimping into a single step, enabling quick and reliable field termination of LC and SC connectors.

In particular, singlemode optoelectronics rely on much more powerful and precise light sources and can cost 2 to 4 times more than multimode optoelectronics. Also, multimode media is typically easier to terminate and install in the field than singlemode. Additionally, it is always more cost-effective to transmit at 850 nm for multimode applications and at 1310 nm for singlemode applications. Finally, optoelectronics that use multiple transmit lasers (e.g. 10GBase-LX4 uses four separate laser sources per fiber) or other multiplexing techniques cost significantly more than optoelectronics that transmit over one wavelength.

A good rule of thumb is to consider multimode fiber to be the most cost-effective choice for applications up to 550 meters in length.

Optical fiber cabling configurations

Optical fiber cabling is typically deployed in pairs; one fiber is used to transmit and the other is used to receive. Due to its extended distance support of applications compared to balanced twisted-pair cabling, optical fiber cabling is the perfect media for use in customer-owned outside plant (OSP), backbone cabling, and centralized cabling applications.

Customer-owned OSP cabling is deployed between buildings in a campus environment and includes the terminating connecting hardware at or within the structures. Interestingly, customer-owned OSP cabling is typically intended to have a useful life in excess of 30 years, so great care should be taken to specify robust cabling media. Requirements pertaining to customer-owned outside plant cabling and pathways can be found in ANSI/TIA-758-A and BS EN 50174-3.

Backbone cabling is deployed between entrance facilities, access-provider spaces, service-provider spaces, common equipment rooms, common telecommunications rooms, equipment rooms, telecommunications rooms, and telecommunications enclosures within a commercial building. Backbone cabling must be configured in a star topology and may contain one (main) or two (main and intermediate) levels of crossconnects. Backbone cabling requirements are specified in ANSI/TIA-568-C.0, ANSI/TIA-568-C.1, and ISO/IEC 11801 Ed2.0.

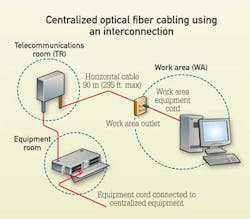

Centralized optical fiber cabling may be deployed as an alternative to the optical crossconnect to support centralized electronics deployment in single-tenant buildings. Centralized optical fiber cabling supports direct connections from the work area to the centralized crossconnect via a pull-through cable and the use of an interconnect or splice in the telecommunications room or enclosure. Note that the maximum allowed distance of the pull-through cable between the work area and the centralized crossconnect is 90 meters (295 feet). Centralized cabling requirements are specified in ANSI/TIA-568-C.0, ANSI/TIA-568-C.1, and ISO/IEC 11801 Ed2.0.

Optical fiber cabling may also be used in the horizontal cabling infrastructure, although there are no provisions allowing extended distance in the TIA and ISO standards.

Horizontal cabling is deployed between the work area and the telecommunications room or enclosure. Horizontal cabling includes the connector and cords at the work area and the optical fiber patch panel. A full crossconnect or interconnect may be deployed along with an optional multi-user telecommunications outlet assembly (MUTOA) or consolidation point (CP) for a total of four connectors in the channel. The maximum horizontal cable length shall be 90 meters (295 feet) and the total length of work area cords, patch cords or jumpers, and equipment cords shall be 10 meters (32 feet) for both optical fiber and balanced twisted-pair cabling channels. Horizontal cabling requirements are specified in ANSI/TIA-568-C.0, ANSI/TIA-568-C.1, and ISO/IEC 11801 Ed2.0.

Optical fiber cable

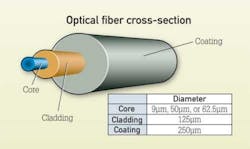

The optical fiber that enables light transmission is actually an assembly of three subcomponents: the core, the cladding, and the coating. The core is made of glass (or, more accurately, silica) and is the medium through which the light propagates. The core may have an overall diameter of 9 µm for singlemode or 50 µm or 62.5 µm for multimode transmission. Surrounding the glass is a second layer of glass with a vastly different index of refraction that focuses and contains the light by reflecting it back into the core. This second layer is called the cladding and, regardless of the glass core construction, has an overall diameter of 125 µm. Combining the core and cladding diameters is the source of optical fiber descriptors, such as 50/125 µm or 62.5/125 µm, that are applied to optical fibers commonly used for telecommunications applications. The purpose of the outermost layer, called the coating, is to add strength and build up the outer diameter to a manageable 250-µm diameter (about three times the diameter of a human hair). The coating is not glass, but rather a protective polymer such as urethane acrylate, that may be optionally colored for identification purposes.

Cabling optical fibers makes them easier to handle, facilitates connector termination, provides protection, and increases strength and durability. The cabling process differs depending upon whether the optical fibers are intended for use in indoor, outdoor, or indoor/outdoor environments.

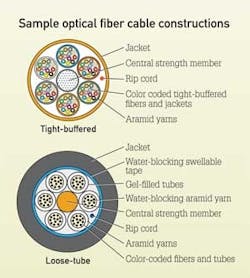

Indoor optical fiber cables are suitable for inside (including riser and plenum) building applications. To facilitate connector terminations, a 900µm plastic buffer is applied over the optical fiber core, cladding, and coating subassembly to create a tight buffered fiber. Up to 12 tight buffered fibers are then encircled with aramid yarns for strength, and then enclosed by an overall flame-retardant thermoplastic jacket to form a finished optical fiber cable. For indoor cables with higher than 12-fiber counts, groups of jacketed optical fiber cables (typically 6- or 12-fiber count) are bundled together with a central strength member (for support and to maintain cable geometry) and are enclosed by an overall flame-retardant thermoplastic jacket. Supported fiber counts are typically between 2 and 144.

Outdoor (also known as outside plant or OSP) optical fiber cables are used outside of the building and are suitable for lashed aerial, duct, and underground conduit applications. To protect the optical fiber core from water and freezing, up to 12 250-µm optical fiber cores are enclosed in a loose buffer tube that is filled with water-blocking gel. For up to 12-fiber applications, the gel-filled loose tube is encircled with water-blocking tapes and aramid yarns and enclosed within an overall ultraviolet and water-resistant black polyolefin jacket. For outdoor cables with higher than 12-fiber counts, groups of loose buffer tubes (typically 6- or 12-fiber count) are bundled together with a central strength member and water-blocking tapes and aramid yarns and then enclosed within an overall ultraviolet and water-resistant black polyolefin jacket. Corrugated aluminum, interlocking steel armor, or dual jackets may be applied for additional protection against crushing and rodent damage. Supported fiber counts are typically between 12 and 144.

Several of the optical interconnection technologies described in this article are shown here. Clockwise from upper left are MTP/MPO-style trunking cable assemblies, duplex LC-connected optical fiber cables, plug-and-play array modules (one with MPO/MTP-style connectors showing and the other with LC connectors showing), and a pass-through adapter plate.

Indoor/outdoor optical fiber cables offer the ultraviolet and water resistance benefits of outdoor optical fiber cables combined with a fire-retardant jacket that allows the cable to be deployed inside the building entrance facility beyond the maximum 15.2-meter (50-foot) distance that is specified for OSP cables. Note that there is no length limitation in countries outside of the United States that do not specify riser- or plenum-rated cabling. The advantage of using indoor/outdoor optical fibers cables in this scenario is that the number of transition splices and hardware connections is reduced. Indoor/outdoor optical fiber cables are similar in construction to outdoor optical fiber cables except that the 250-µm optical fiber cores may be either tight buffered or enclosed within loose buffer tubes. Loose tube indoor/outdoor optical fiber cables have a smaller overall diameter than tight buffered indoor/outdoor optical fiber cables, however tight buffered indoor/outdoor cables are typically more convenient to terminate because they do not contain water-blocking gel or require the use of breakout kits (described later).

Shown here is a typical schematic for centralized optical fiber cabling using an interconnection; the centralized system supports direct connections from the work area to the centralized crossconnect via a pull-through cable and the interconnect.

Optical fiber interconnections

Unlike the plug-and-jack combination that makes up a mated balanced twisted-pair connection, an interconnection is used to mate two tight-buffered optical fibers. An optical fiber interconnection typically consists of two plugs (connectors) that are aligned in a nose-to-nose orientation and held in place with an adapter (also called a coupler or bulkhead). The performance of the optical fiber interconnection is highly reliant upon the connector’s internal ferrule and the adapter’s alignment sleeve. These components work in tandem to retain and properly align the optical fibers in the plug-adapter-plug configuration. The internal connector ferrule is fabricated using a high-precision manufacturing process to ensure that the optical fiber is properly seated and its position is tightly controlled. The high tolerances of the alignment sleeve ensure that the optical fibers held in place by the ferrule are aligned as perfectly as possible. Although more expensive, ceramic alignment sleeves maintain slightly tighter tolerances than metal or plastic alignment sleeves, are not as susceptible to performance variations due to temperature fluctuations, and may be specified for extremely low-loss applications.

Accurate plug-adapter-plug alignment minimizes light energy lost at the optical fiber interconnection and maintaining precision tolerances becomes especially critical as the optical fiber diameter decreases. For example, if two 62.5-µm optical fibers are off-center by 4 µm in opposite directions, then 13% of the light energy escapes or is lost at the interconnection point. This same misalignment in a 9-µm singlemode fiber would result in almost a total loss of light energy. The critical nature of the core alignment is the reason why different optical fiber types, including 62.5-µm and 50-µm multimode fiber, should never be mixed in the same link or channel.

Optical fiber breakout kits are used to facilitate termination of loose-tube optical fibers used in indoor/outdoor and outdoor applications. Once the water-blocking gel is thoroughly removed from the optical fibers, the breakout kit allows furcation tubes (typically 1.2mm to 3.0mm in diameter) to be installed over the 250-µm optical fibers, increasing the diameter and forming a short “jacket” so that the optical fibers may be terminated to the desired optical fiber connector. Selection of the correct furcation tube ensures compatibility with all optical fiber connectors.

Users can choose from many optical fiber connector options.

Traditional optical fiber connectors are represented by the SC and ST connector styles. These two types of optical fiber connectors were recognized when optical fiber cabling was described in the first published TIA and ISO/IEC telecommunications cabling standards. The ST connector features a round metal coupling ring that twists and latches onto the adapter and is only available as a simplex assembly (two assemblies are required per link or channel). SC connectors feature a quick push-pull latching mechanism and have an advantage in that they may be used in conjunction with a duplex clip that more easily supports the interconnection of the two optical fibers in a link or channel. SC optical fiber connectors are generally recommended over ST optical fiber connectors for use in new installations due to their duplexing capability. Both ST and SC connectors may be field-terminated using an epoxy/polish or mechanical splice method.

Singlemode fiber cores are 9 µm in diameter, while multimode fiber cores may be 50 or 62.5 µm. Regardless of core size, the cladding is 125 µm and the coating 250 µm.

Small form factor (SFF) refers to a family of optical fiber interfaces that support double the connector density of traditional optical fiber connectors. The most common SFF interface is the LC connector, with the MT-RJ having some limited legacy market presence. Both interfaces feature duplex configurations and a small pluggable form with external plug latch that is approximately the same size as the 8-position modular plug used for copper connections. The LC connector may be field terminated using an epoxy/polish method or mechanical splice method. The MT-RJ connector is field terminated using a traditional no-epoxy/no-polish mechanical splice termination method. The main difference between the MT-RJ and LC optical connector is related to the performance of the internal ferrule. The LC’s internal ferrule maintains sufficiently tight tolerances to fully support both singlemode and multimode applications, while the MT-RJ connector is recommended for use in legacy applications only. Field termination of MT-RJ connectors is not recommended for singlemode applications.

Array optical fiber connectors are the newest recognized style of optical fiber interfaces and are intended to support extremely high-density environments as well as emerging technologies such as 40GBase-SR4 and 100GBase-SR10 that will require more than two optical fibers per link or channel. There are typically 12 or 24 fibers in an array connector, although one array connector may support as many as 144 fibers. A multi-fiber push on (MPO) style interface is the most basic array interface. MTP optical fiber connectors are intermateable with MPO connectors; however they are engineered to deliver improved mechanical and optical performance and are recommended for deployment in new installations. MPO/MTP connectors cannot be field terminated. Array or “plug-and-play” modules are self-contained and typically support the interconnection of two, 12-fiber MPO/MTP interfaces with 24 LC connections or one 12-fiber MPO/MTP interface with 12 SC or LC connections.

Optical fiber cabling deployment

The most common optical fiber cabling deployment approach is to field terminate the optical fiber connectors to the optical fiber cable using the appropriate epoxy/polish or no-epoxy/no-polish mechanical termination method. However, the new MPO/MTP plug-and-play modules and MPO/MTP array connectors are not supported by field termination and there are considerations, such as installer expertise and the IT construction/upgrade schedule, that may favor the use of factory-terminated pigtails or trunking assemblies over field termination methods.

The environment in which the fiber cable will be used, e.g. indoor or outdoor, will determine the cable’s construction and the treatment of the fibers within that cable.

The pros and cons of these termination methods are described here.

Field termination supports the lowest raw material cost for SC, ST, LC, and MT-RJ optical fiber cabling systems. However, the time needed for field termination is the longest of the three deployment options and installer skill-level requirements are higher, which may increase the project installation costs. No-epoxy/no-polish and certain mechanical-splice-style termination methods require less installation skill than the epoxy/polish method, however the connectors used in conjunction with mechanical termination methods are more expensive and the performance (especially using the no-epoxy/no-polish method) may be lower and more variable.

Optical fiber pigtails feature a factory preterminated and tested SC, ST, LC or MT-RJ optical fiber connector and a 1-meter stub of 62.5/125-µm multimode, 50/125-µm multimode, or singlemode optical fiber. The stub end of the pigtail is then fusion-spliced to the optical fiber. Fusion splicing provides a consistent, nearly loss-free termination and can be fast with proper technicians and equipment. The main benefits to this approach are the assurance of low-loss performance at the interconnection and the elimination of the need for endface inspections and possible connector reterminations.

Trunking cable assemblies provide an efficient alternative to field-terminated components or splice connections and allow up to 75% faster field deployment times. Trunking cable assemblies are custom factory preterminated and tested lengths of optical fiber cable terminated on both ends with SC, ST, LC, MT-RJ, or MPO/MTP optical fiber connectors that are simply pulled and plugged in. When deploying trunking cable assemblies, cable-length specification is critical and precise planning is required up front. Trunking cable assemblies that have an MPO/MTP connector on one or both ends are commonly referred to as “plug-and-play” cable assemblies. MPO/MTP plug-and-play cable assemblies have the smallest connector profile and, therefore, have the smallest pathway, cabinet, and rack-space requirements of all trunking cable assembly options.

Always maintain the fibers’ polarity to ensure the transmit fiber is matched to the receive port on each end of the link or channel.

Valerie Maguire is global sales engineer with Siemon (siemon.com).