Performance, installation practices, required equipment and total cost all factor into deciding which fiber-connectivity method best suits your needs.

By Sara Chase, Corning Cable Systems

Over the past couple decades, as technologies in fiber-optic termination have advanced, it has become easier to install a connector. Several proven technologies are used to terminate an optical fiber in the field. The most common termination methods are no-epoxy/no-polish, epoxy-and-polish, and pigtail splicing. Understanding when to use one technique over another to reduce cost and maximize resources can be challenging.

When it comes to specifying a connector type for a project, benefits and tradeoffs associated with each termination method must be considered in conjunction with the installation environment. Understanding the basics and knowing what factors to consider will help in making an informed decision. These factors include connector performance, tools and consumables needed, installation ease and environment, and total cost.

No-epoxy/no-polish

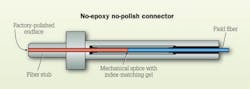

One way to terminate the end of a fiber in the field is to use a no-epoxy/no-polish (NENP) connector. An NENP connector is installed without the use of an epoxy or having to polish the endface. Instead, the connector’s endface is precisely polished in the factory, and the field fiber is mechanically spliced to a factory-cleaved fiber stub, as shown in the illustration on this page.

This type of field termination is the fastest and simplest for a new installer to master. The installation process begins with preparing the field fiber, which is done by stripping the protective coating down to bare glass. Once the fiber is cleaned, it is then cleaved with a precision cleaver. Next the field fiber is inserted into the connector until it is seated against the factory-stubbed fiber and locked into place mechanically by a rotating cam or other means. Typically this step is achieved by using a tool that holds the connector and activates the mechanical splice by a button or lever. Some NENP installation tools provide the installer with real-time feedback indicating whether or not the connection is good.

Epoxy-and-polish

Using an epoxy-and-polish (EP) connector is another common termination method. This type of connector is installed using an epoxy to form a bond between the field fiber and the connector’s ferrule, and then hand-polishing the endface. The most common types of EP connectors use heat- or anaerobic-curing techniques. A heat-cure connector uses heat to harden an epoxy, which takes several minutes. An anaerobic EP connector uses a two-part epoxy, a hardener that is inserted into the connector and an activator on the fiber. The curing time for an anaerobic connector is approximately one minute.

Terminating an EP connector is labor-intensive and can be challenging for a new installer. Someone new to installing EP connectors will need a lot of training and practice before being able to consistently produce connectors that are within spec. To begin terminating an EP connector, an epoxy must be inserted into the connector ferrule. Next, the field fiber is stripped down to the bare glass and cleaned. If the type of connector is an anaerobic, the bare fiber is painted with an activator and inserted into the connector. If it is a heat-cure connector, the fiber is inserted into the connector and placed in an oven for the epoxy to cure. Once the epoxy has been cured, the fiber stub that is protruding above the ferrule is scribed and removed. The final step is to polish the endface of the connector using a fixture and several different polishing films. Hand-polishing a connector is 100-percent dependent on following manufacturer instructions and installer technique and experience.

Pigtail splicing

Pigtail splicing is another technique commonly used to terminate an optical fiber. This method is accomplished by fusing the field fiber to a factory-made pigtail in a splice tray.

A pigtail is a piece of fiber or cable with one or more factory-polished connectors on one end and bare fiber on the other. When splicing pigtails, the installer will need a fusion splicer, splice trays and hardware, and splice protectors such as heat shrinks. The first step in pigtail splicing is to secure and route the fiber-optic and pigtail cable in a splice tray. Next, the bare fiber end of the cable assembly is spliced to the field fiber using a fusion splicer. Finally, the splices are routed into the splice tray and the tray into the hardware.

Factors to consider

When thinking about what type of field termination method to use for a project, there are several factors to consider. Each factor should be given its own weight based on the specific requirements for that project. Knowing what these factors are ahead of time will allow one to effectively choose a connector type that is appropriate for a specific installation scenario. Factors to consider include connector performance, installation ease and environment, equipment needed and total cost.

For a fiber-optic installation to be successful, it should be carried out in accordance with industry standards. Connector performance plays a big part in whether a system passes or fails attenuation and reflectance measurements. For the three common termination methods, consistently obtaining a 0.5-dB maximum attenuation loss per connector pair is not difficult as long as the manufacturer’s installation procedures are followed. Connector reflectance is not as easily obtained for each method. Connectors installed using the NENP and pigtail-splicing methods are polished in a factor to make sure they achieve a certain level of performance as far as endface quality. When installing an EP connector, it is difficult to consistently produce endfaces that meet industry standards in regard to connector reflectance, even if the installer is experienced. Certain electronic scenarios depend on connector reflectance more than others; higher-data-rate systems are examples of scenarios that rely more heavily on connector reflectance. A system may be working today, but it may fail as it is upgraded to a higher data rate. A reason for that could be high connector reflectance or modal noise. Therefore, if it is known that a system will need to perform at higher data rates above 1 Gbit/sec now or in the future, the termination method selected should be NENP or pigtail splicing. Also, if installing a singlemode system with a low-reflectance connector such as an APC connector, an NENP or pigtail-splicing termination must be used. This is because an APC connector cannot be polished in the field.

Installation issues

When considering what type of connector to use, installation ease is a significant contributor. Each termination method requires a different skill level. The skill level needed determines how much effort and time is needed to train new installers and the time it takes to complete a termination. An NENP connector does not require an installer with a high skill level comparative to other methods. A new installer can be trained on how to install an NENP connector in several hours and can install a connector every couple of minutes. On the other hand, the skills needed to hand-polish connectors or fiber routing in splice trays is more difficult and takes longer to teach. An experienced installer can install an EP connector every five minutes and splice on a pigtail every two to three minutes. Therefore, if a termination method is needed when the installation crew is new, an NENP connector should be used because it is the easiest method to learn quickly. If time is of the essence, and the installers are fully trained, either pigtail splicing or an NENP method should be used. Splicing on a pigtail is a serial installation process, while NENP is parallel and more efficient.

The installation environment is also a determining factor when it comes to selecting a connector type. Both EP and pigtail-splicing termination methods need a workspace such as a table. If a large number of connectors are being installed in one room, NENP, EP or pigtail splicing can easily be accomplished. If the installation is in a hard-to-reach space or there are only a couple connectors at each station, an NENP should be used because little to no workspace is needed for that method.

Epoxy and Polish | No-Epoxy/No-Polish | Pigtail Splicing | |

Level of Design Experience | Medium | Low | Medium |

Performance | 0.5 dB max for 1G | 0.5 dB max for 1G and 10G | 0.5 dB max for 1G and 10G |

Estimated Time to Complete | 5 minutes | 2 to 3 minutes | 2 to 3 minutes |

Installer Skill Level Required | Medium | Low | High |

Requirements of Site Location | Workspace needed | Quick to install | Workspace needed |

Tools Required | EP toolkit | NENP toolkit | Fusion splicer |

Switching Cost or Initial Investment | Medium | Medium | High |

Maintenance of Equipment | None | Cleaver | Fusion splicer and cleaver |

Consumables Needed | Yes | No | Yes |

Connector Cost | Low | High | High |

Equipment and costs

Another consideration to make when selecting a termination method is the equipment needed. Each method requires either a kit or a splicer. If the installer already has the equipment required to use a certain method, they will be more likely to use that method because they would only have to worry about purchasing consumables. The initial investment for installing NENP and EP connectors is a toolkit, and for pigtail splicing it is a fusion splicer. The purchase price for a fusion splicer will be much greater than that for the connector toolkits. An alternative to purchasing the equipment would be to rent it. Consumables or extra material may also be needed for an installation. No consumables are needed for an NENP installation though. When terminating EP connectors, consumables include epoxy and polishing films. Also, if a heat-cure connector is being installed, an oven and some form of power are needed. When splicing pigtails, the extra materials required are splice protection, trays and hardware. All consumables and extra material needed will add to the overall cost of the installation.

Cost is another aspect when selecting a termination method. When comparing cost for individual connectors or pigtails, EP connectors are low, whereas NENP connectors and pigtails are higher. The total cost of the connector is much more than just the individual cost though. All of the considerations discussed already have an associated cost and should be considered when selecting a termination method. Equipment, consumables, training and installation time all add to the overall cost of the connector.

There are multiple determinants that go into selecting a termination method. The table included on page 26 of this article compares and contrasts several major considerations. Selecting an NENP, EP or pigtail-splicing method depends on what kind of connector performance is needed, how familiar an installer is with the technology, whether or not they own the required tools, how quickly the termination needs to be done and the overall cost.

Installers of fiber-optic systems as well as the ultimate owners and managers of these systems will be well-served by considering all these factors before making a decision.

Sara Chase is technical marketing specialist with Corning Cable Systems (www.corning.com/cablesystems).