Automated endface inspection is an effective means of ensuring fiber connectors meet specifications.

BY MATT BROWN, JDSU

It is widely known in the fiber-optic industry that scratches, defects and dirt on fiber-optic connector endfaces negatively impact network performance. As fiber penetrates further into the network, the need to deal systematically with dirty and damaged optical connectors becomes increasingly critical to network performance.

In the effort to guarantee a common acceptable level of connector performance throughout the entire fiber-optic lifecycle, the International Electrotechnical Commission (IEC; www.iec.ch) created Standard 61300-3-35, which specifies both the pass/fail requirements for endface quality and a process to verify the connector meets these requirements.

A major challenge in achieving compliance to the standard lies in the uncontrollable variables associated with manual inspection and analysis, the method most often used today. Technician eyesight and expertise, ambient lighting and display conditions-all of these variables keep manual inspection and analysis from being a 100-percent reliable and repeatable method of assuring IEC compliance.

In order to help technicians achieve compliance to the standard when using manual visual inspection equipment, the IEC standard mandates the use of a systematic process for fiber handling every time two fibers are connected.

Inspect before you connect

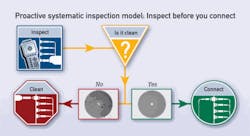

The following simple, four-step model effectively guides technicians of varying expertise levels in the proper implementation of systematic proactive inspection.

• Step 1: Inspect. Use the microscope to inspect the fiber. If the fiber is dirty, go to Step 2. If the fiber is clean, go to Step 4.

• Step 2: Clean. If the fiber is dirty, use a cleaning tool to clean the fiber endface.

• Step 3: Inspect. Use the microscope to reinspect and confirm the fiber is clean. If the fiber is still dirty, go back to Step 2. If the fiber is clean, go to Step 4.

• Step 4: Connect. If both the male and female connectors are clean, they are ready to connect.

Consistent use of the IBYC (Inspect-Before-You-Connect) model ensures that proactive inspection is performed correctly every time that fiber-optic endfaces are cleaned prior to mating, eliminating the installation of dirty or damaged fibers into the network and optimizing network performance. This effectiveness is why IBYC has been incorporated into manufacturing procedures for the majority of the world's leading organizations using fiber, increasing knowledge of this process and helping it become routine practice around the world.

Inspection alone is not enough

While research shows that systematic proactive inspection using models like IBYC to achieve IEC standard compliance is eliminating the installation of contaminated fibers and improving network performance, only through the automation of inspection and analysis using software programmed to the IEC standard will all variables be eliminated, the quality of the connector be documented and verified, and a 100-percent and reliable process be guaranteed.

Automation is the only way to assure compliance because the IEC standard requires the user to know the exact location and size of surface defects, such as scratches, pits and debris on the fiber-optic connector endface. In order to understand why this is important, it helps to understand the reason the standard was created and how it was developed.

IEC 61300-3-35

The IEC Standard 61300-3-35 is a global common set of requirements for fiber-optic connector endface quality designed to guarantee insertion loss and return loss performance. The standard contains pass/fail requirements for inspection and analysis of the endface of an optical connector, specifying separate criteria for different types of connections, such as SM-PC, SM-UPC, SM-APC, MM and multifiber connectors. Copyrighted copies of the document are available for purchase at www.ansi.org.

The criteria established in 61300-3-35 are designed to guarantee a common level of performance in an increasingly difficult environment, where fiber is penetrating deeper into the network and being handled by more technicians. In many cases technicians handling fiber are not familiar with the criticality of fiber-optic connector endface quality, nor do they possess the experience and technical knowledge required to properly assess that quality.

The quality values used in the IEC standard are the result of years of extensive testing of scratched, damaged or dirty optical connectors. The testing was conducted by a coalition of industry experts including component suppliers, contract manufacturers, network equipment vendors, test equipment vendors and service providers. This work has been published previously in a number of papers.

Understanding the variables and limitations of manual visual inspection is critical. The IEC used an automated objective inspection and analysis software to develop the 61300-3-35 standard. Automating the pass/fail process using research-based parameters from testing conducted by the aforementioned industry coalition enabled the IEC to specify a repeatable standard of quality that would guarantee a common level of performance, thereby creating a positive impact on product performance as well as overall network performance.

The standard's purpose

The standard is designed to be used as a common quality reference between supplier and customer, and between work groups in the following ways.

As a requirement from the customer to the supplier (e.g. integrator to component supplier or operator to contractor)

As a guarantee of product quality and performance from the supplier to the customer (e.g. manufacturer to customer, contractor to network owner, or between work groups within an organization)

As a guarantee of network quality and performance within an organization

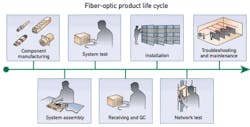

As more stages in the fiber-optic product lifecycle are outsourced to disparate vendors, the standard takes on renewed importance in ensuring the optimized performance of today's fiber-dense networks.

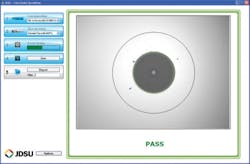

Tools for compliance

Using a fiber-optic inspection and analysis software program that is preloaded with the IEC standard specifications, any technician can effectively inspect and certify compliance with IEC 61300-3-35 or other customer-specified standards. Such a program also enables a technician to implement simple pass/fail acceptance testing without any necessary skill in quality judgment, and to generate detailed analysis reports that can be archived.

Automated inspection and analysis presents several advantages over subjective, manual inspection. It eliminates variation in results, certifies and records product quality at the time of inspection, enables technicians of all skill levels to reliably and systematically certify quality, makes advanced pass/fail criteria easy to use, and improves product and network performance as well as yields.

By providing improved repeatability and stability of inspection analysis throughout the fiber-optic product lifecycle, the combination of common requirements (found in the IEC 61300-3-35 standard), a systematic process, and automated inspection and analysis combine to ensure consistent product performance regardless of the number and expertise of vendors and technicians involved in the manufacture, installation and network-administration processes.

The business impacts of reliable, repeatable automated fiber-optic connector inspection and certification include the following.

Insured and repeatable product quality through the certification of connector endface condition at installation

Assurance of customer satisfaction and supplier protection through the reliable documentation of connector endface quality

Competitive advantage for component and system vendors as well as for installation contractors who cost-effectively document endface quality

A common, repeatable system that provides correlation through the supply chain

These benefits make automated endface inspection the most effective method available to assure and certify compliance with the IEC 61300-3-35 standard throughout the fiber-optic product lifecycle, and to achieve the promise of next-generation networks.

MATT BROWN is director of product management for fiber inspection and test with JDSU (www.jdsu.com).