Knowing each style's pros and cons will help you make the right selections for different applications.

By Tony Casazza, QuickTreX

In spite of the recession, fiber-optic cabling sales have been on the rise for the past five years. This is due in part to modern-day bandwidth intensive applications, growth of fiber to the premise (FTTP) applications, and the notion of some industry pundits who believe that copper cabling is reaching its limits. In addition, the perception that fiber-optic cabling is too difficult to install or too expensive, has virtually disappeared. Many people–from homeowners to network managers and system engineers–are discovering that fiber-optic cabling and technology are feasible.

Fiber-optic installations will likely continue to proliferate for decades to come. Presently there is a growing need for fiber-optic cabling installations both inside and outside plant, horizontal or vertical. Given the need and the growth of fiber-optic installations, it is important to stay current on trends in fiber-optic cabling termination styles and tools–no matter what segment of the industry you are from. Here is a description of different terminationPreterminated cable assemblies such as these offered by QuickTreX feature secure factory-terminated ends with connectors that are staggered and held in place by the sheathing.

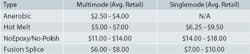

Heat cure epoxy and polish. This termination style was the original fiber-optic termination, which is still popular with high-volume installation or factory assembly houses due to its low cost, low loss and overall dependable and stable performance. This style is typically too cumbersome for field use, and unless done in a controlled environment, the yield will be low. This style of termination also requires the most supervised skills training, especially for polishing.

Easy cure epoxy and polish (hot-melt, anaerobic, etc.). This termination style is popular with contractors who have gotten accustomed to this type of termination. While field installable and relatively low cost, low loss, dependable and stable in most environments except those experiencing very hot temperatures, they still require polishing, offer less than 100 percent yield, and are relatively time consuming.

No-epoxy/no-polish connectors (prepolished connectors with mechanical splice).This style of fiber-optic termination is the fastest and easiest to install, making it a popular choice for anyone who needs to terminate optical fiber in the field. Latest advancements in this type of connector have improved yield, and little or no training is required. The downside is that these connectors are relatively expensive, and although no-epoxy/no-polish connectors are dependable, factory-terminated or fusion-splice type connectors are considered to be more robust and dependable. In addition, proprietary tooling is required, and there is the possibility of back reflection issues with some singlemode applications.

Fusion splice connectors (no-epoxy/no-polish/fusion splice). This termination style is popular with telcos, long-distance carriers, and the military due to the fact that its performance is as good as a factory preterminated connector with very low back reflection. However, this style requires an expensive fusion splicer that can cost more than $7,000. The connector costs are at a mid-price point.

Fusion splicing of factory preterminated pigtails. Also popular with telcos, long-distance carriers, and the military, this type of termination method offers performance that is as good as a factory preterminated connector with very low back reflection. Again, this termination method requires an expensive fusion splicer, and connector costs are at a mid-price point.

Factory preterminated multifiber assemblies. Popular with end users and installation contractors, this termination type requires no training and no startup costs, and is the best and most reliable factory termination with very low back reflection. These connectors however require precise premeasurement as well as potential lead time when ordering.

Termination evolution

Since the late 1970s, various connectors and termination methods have been brought to market. The goal for each new connector or termination method has been better performance (less light loss and reflectance) and easier, faster, and less expensive termination. Early fibers were fragile and difficult to work with, and in the beginning, oven-cure epoxy connectorization was the only game in town. Then hot-melt and anaerobic epoxies made termination a little easier with their no-fuss bonding procedures. However, they still required polishing, which is labor intensive and reduces yield. Early crimp type (no-epoxy) designs eliminated the use of epoxy altogether but still required polishing. The inevitable demise of virtually all the crimp (no-epoxy) connectors was due to their notorious unreliability, and there is only one system on the market today whose manufacturer claims high reliability.

Early on, mechanical field splices were considered to be a fast, economical, and easy way to join two fibers together. They coexisted with both epoxy/polish connectors and factory preterminated assemblies for years. Then the two styles were married, giving rise to the present day no-epoxy/no-polish connectors, which are currently available in OM1, OM2, and OM3 multimode optical fiber types and singlemode optical fiber.

Factory pretermination brought forth a huge advantage to those engaged in field installation work. These prepolished/mechanical splice connectors took away virtually all of the learning curve, consumables, and lack of yield associated with the previous styles. They consist of a fiber-optic connector that includes a very short section of fiber that is factory terminated and polished on its endface. Inside of the connector body is a perfectly cleaved fiber end with optical matching gel that basically mimics a mechanical splice. One of the keys to a perfect termination depends heavily on the user inserting a perfectly cleaved fiber that is matched together with the optical matching gel to connect it to the internal factory-cleaved and polished fiber. This makes a good reliable splice and thus a relatively low-loss connector assembly.

Until recently, terminating connectors onto singlemode cable in the field was considered impractical. Over the years of modern fiber-optic termination, it has become popular to fusion splice pigtails with connector ends that were factory preterminated onto the singlemode fiber strands. Hence, fusion splice connectors were born. Instead of using a mechanical splice, these factory preterminated connectors are terminated to fiber through the electric arc process known as fusion splicing. Modern fusion splicing is virtually lossless and has the tensile strength of an unbroken piece of fiber.

Fusion splice connector systems are ideal for high-end demanding applications that require the most robust, reliable terminations under the harshest conditions. Basically, these no-polish/fusion connector systems are equivalent to factory preterminated assemblies. They will tend to have lower loss compared to prepolished mechanical splice type (no-epoxy/no-polish) connectors. And even more importantly, fusion splice connectors will have virtually no back reflection, which is vital in critical singlemode applications.

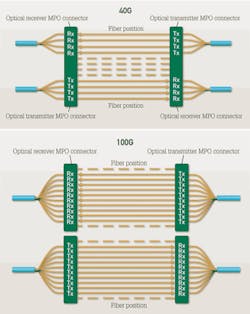

40- and 100-Gbit Ethernet parallel-optics transmission will use 12-fiber MTP/MPO connectors. 40-Gbit transmission will use a single 12-fiber connector, with four lanes of transmit and four lanes of receive. 100-Gbit transmission will use two 12-fiber connectors, with 10 lanes of transmit and 10 lanes of receive on each.

Technology advancements

Virtually all of the advancements in the manufacturing and technology of fiber-optic connectors have delivered benefits to the installation and performance of fiber-optic systems. No-epoxy/no-polish mechanical type connectors have come a long way in ease of use, performance, and reliability. Over the past several years, manufacturers have continually tweaked and revamped these connectors to the point where they are now considered very reliable for most applications. These easy-to-terminate connector systems are now available from several industry manufacturers, and they have become popular for field termination, with several million sold since their introduction, especially for multimode fiber-optic LAN and other field applications.

Because fusion splicing machines have decreased in price and increased in features and quality like many other technologies, prepolished/fusion splice connectors are now gaining traction in the market. Whereas 10 years ago a fusion splicer was big and bulky and cost approximately $25,000, today's units are smaller, lighter and more efficient, and they typically cost $7,000 to $12,000. Due to the tighter tolerances of fibers manufactured in the last 10 years, the less-costly "cladding alignment" type fusion splicers have become more mainstream and acceptable for critical work. Although a fusion splicer is still an expensive tool, its cost can be easily justified, providing a return on investment in many high-end or high-volume applications.

Termination considerations

Unlike copper cabling with very inexpensive tooling, fiber-optic termination startup costs are typically much higher. Toolkits required for most no-epoxy/no-polish (mechanical) systems range from about $700 to $2,000 with an average cost of $1,500. These toolkits usually contain a high-quality cleaving machine, a proprietary locking (or crimping) device, and other tools and accessories needed for stripping and handling fiber. Since these systems are usually proprietary, installers are limited to using that particular manufacturer's brand of connectors with the tooling. For example, if you are terminating ST-style connectors and the toolkit purchased does not accommodate them, you would need to purchase a whole different new platform. It's important to be careful when choosing a fiber-optic system. Due to the high cost of fusion splicing machines, some installers may also choose to rent a fusion splicer on an as-needed basis.

Due to high startup costs of most other field termination systems, combined with the need for skilled field installation, factory preterminated assemblies have gained steadily in popularity over the past five years, even with many veteran installers who are skilled in epoxy/polish termination. The table on page 42 demonstrates some of the reasons for this shift to factory preterminated assemblies.

Most vendors of factory preterminated assemblies will allow for customized ordering to the customer specifications, which includes fiber type, length, fiber count, connector style, and other characteristics. The most popular connector styles ordered are ST, SC, LC, and MTP/MPO. Most vendors will offer breakouts with 2- or 3-mm color-coded buffer tubes as standard equipment. A quality assembly should also be accompanied by a test report showing the dB loss on all of the strands. Since the early days of fiber, construction methods for preterminated assemblies have been refined and are proven to yield a very high installation success rate. QuickTreX claims a 99.8 percent success rate for preterminated assemblies over 13 years of sales.

Common questions asked by customers ordering factory preterminated assemblies include, "How thick is the pulling sock?" and, "What is the minimum bend radius for the cable?" Generally these questions are asked in attempts to determine a conduit size for the run. The pulling sock is not much thicker than the cable itself because the connectors inside are staggered. However, installers should not choose a conduit size based on the thickness of the pulling sock, nor should they choose it based on the minimum bend radius of the fiber cable. Conduit size should be determined by how many bends are in the run, the length of the run, and the anticipated pulling force required to install the cable. Generally, it is advisable to oversize the conduit and replace bends with pull-boxes wherever possible.

MTP/MPO-style connectors

In June 2010, the IEEE released the 802.3ba 40- and 100-Gigabit Ethernet standards for OM3 and OM4 multimode fibers. To achieve these speeds, parallel optics is required, where the load is split into separate 10-Gigabit channels. A 40-Gig channel requires eight fibers with four transmitting at 10 Gig and four receiving at 10 Gig. A 100-Gig channel requires 20 fibers with 10 fibers transmitting at 10 Gig and 10 receiving at 10 Gig. The connector required for both is the MTP/MPO 12-fiber connector. Those anticipating moving to 40- or 100-Gigabit Ethernet would be wise to use MTP/MPO-style connectors today.

A 40-Gigabit quad small form-factor pluggable (QSFP) module is designed to split the data load among multiple fibers using an MTP /MPO connector and ribbon fiber assembly. Compliant with SFF-8436, the QSFP features independent transmitter and receiver sections, each with four fibers in parallel. It supports MPO-based multimode fiber interconnects with a transmission distance of up to 150 meters over OM3 multimode fiber. There are basically three ways to field install MTP/MPO cable assemblies.

- Installing factory preterminated MTP/MPO assemblies.

- Fusion splicing factory preterminated MTP/MPO pigtails onto 12-strand ribbon fiber.

- Installing no-epoxy/no-polish MTP/MPO connectors.

Because the technology is rather new and relatively complex, installing factory preterminated MTP/MPO assemblies is currently the best option. Presently, only one manufacturer offers a field installable MTP/MPO connector, and because this is a relatively new and complex technology, most industry experts agree that it is prudent to take a "wait-and-see" approach with this system. In fact, due to their complexity, most fiber cable assembly houses do not even make MTP/MPO assemblies.

Factory preterminated MTP/MPO assemblies can be ordered in custom lengths with pulling socks and pulling eyes on each end. The fact that they have only one (or sometimes two) heads on each end facilitates the small size and rigidity of each pulling sock. Therefore as a general rule, factory preterminated MTP/MPO assemblies are very resilient to forces that they may encounter during a pull.

Listening to the hype surrounding no-epoxy/no-polish connectors will lead one to believe that they are as good as any other termination type, even fusion splice. While they are a viable connector, they do have tradeoffs and limitations. However, if the highest performance is the main concern, the best options include fusion splice pigtails, fusion splice connectors, and factory preterminated assemblies. And as for the use of MTP/MPO assemblies, factory preterminated and fusion splice MTP/MPO pigtails are really the only choices with factory preterminated assemblies winning out by a mile. Until someone invents a machine that allows an installer to load in the connector, simply insert the fiber, and press a button to achieve a perfectly terminated fiber, there will always be many considerations when choosing a fiber-optic termination style.

Tony Casazza is founder and president of QuickTreX, a manufacturer of cabling, connectivity and network components (quicktrex.com).

Past CIM Issues