Understanding the options is essential for controlling labor and material costs.

The optical-fiber industry has come a long way in the past decade, but with so many termination technologies, products, techniques, and procedures from which to choose, selecting the right one for your application can be difficult and will impact how quickly and cost-effectively the job gets done. Advances in machine and mold tolerances, factory automation and adhesives have opened up a world of connector technology options to make termination easier and less expensive.

Fiber terminations fall into one of four basic classifications, which are compared on the following pages:

- No-epoxy/no-polish;

- No-epoxy/polish;

- Epoxy/polish, and

- Pigtail splicing.

Applying these technologies appropriately will have a positive impact on a fiber network's installation costs. Since there is no "one size fits all" solution, it is entirely possible or even recommended to use more than one technology in the same network installation. Understanding the benefits and trade-offs each one offers is the key to selecting the right termination for each part of the installation.

Many enterprises use multiple technologies, depending on the application; for example, some use epoxy/polish connectors in closet locations and no-epoxy/no-polish connectors at the outlets. Similarly, it may make sense to give the testing technicians no-epoxy/no-polish connectors for quickly replacing those connectors that fail to meet the specifications at the time of testing and thus quickly complete the verification process.

The two main factors in installed connector costs are the labor (hours on the job, hours of training, and experience) and material costs (connectors, tools, and consumables). Accordingly, in higher labor-rate areas, it may be advantageous to use a technology with the shortest training and installation time.

As a basis for comparison, consider these factors that affect the termination-installed cost when choosing connection technologies. For purposes of this discussion, it is assumed that all technologies require alcohol and wipes as consumable items, standard cable-preparation tools, and time for transit and cable preparation.

- Setup is the preparation time required before installing the first connector at a termination location, and includes staging the necessary tools and ovens, setting up a termination area and preparing the consumables.

- Installation is the time it takes to install a connector on a single fiber, and includes stripping the buffer, applying and curing the adhesive, polishing, and crimping as required to result in a testable termination.

- Materials include the cost of the connector kit along with the costs of consumables (adhesives, polishing papers) of any protecting hardware and of any necessary tools.

- Skill is also a factor because while some level of training is required for all connector products, some technologies will require skilled technicians while others let installers with limited training get good results. Higher skill usually incurs higher labor costs on an hourly basis.

The most important consideration, whatever connector technology you choose, is always use optical connectors that meet or exceed the requirements established in ANSI/TIA/EIA-568B.3.

Other factors must be considered when choosing a fiber-termination type, including customer choice, product availability, product familiarity, and performance requirements. These factors may require that you select a combination that may not result in the lowest cost. The information that follows, however, may help ensure that the charges for the installation are in line with the true costs:

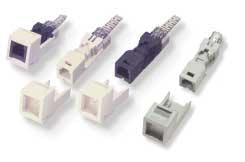

No-epoxy/no-polish connectors

No-epoxy/no-polish connectors offer the easiest and quickest termination technology available. You only need to strip, cleave, and lock the fiber into the connector, which has a short pre-polished fiber stub in the ferrule. In effect, this is a connector with a built-in mechanical splice and a high-quality endface, which provides excellent return-loss performance for a field-terminated connector.

These connectors are ideal for locations with low-fiber-count (less than 24 fibers) cables, such as small building backbones or work area outlets. They're also appropriate for maintenance, repair, and for small moves, adds, and changes. If you have high labor rates, inexperienced technicians, or an inconsistent work force, you will like the fast training and quick installation, and the fact that only a short length of fiber is required for successful termination.

Advantages of no-epoxy/no-polish connectors include the shortest setup time of fiber termination types, shortest installation time per connector, limited training requirement, and lowest consumables costs.

- Setup: Takes about five minutes at each location to set up the polishing station.

- Installation: Takes about two minutes to lock and polish each fiber.

- Materials: A moderate cost for the connector kit, but there is no need for an oven, epoxy or adhesives, which can be expensive consumables. Since you'll need a polishing kit and appropriate fixtures for the connector type, plus polishing papers and fluid consumables, a moderate capital investment is required.

- Skill: Although the locking mechanism is essentially the same for the no-epoxy/no-polish technology, the amount of training and skill is increased because of the polishing procedure; it takes a bit of time to develop a "feel" for how it is done.

No-epoxy/polish connectors

No-epoxy/polish connectors replace the need for epoxy by using a crimp or clamp mechanism to lock the fiber in the ferrule. The excess fiber is then cleaved at the endface and polished to produce a working connector. This is a popular choice because it eliminates two of the industry's primary complaints: the need to mix/apply epoxy and the need for a curing fixture (ovens or lamps that require power).

No-epoxy/polish is ideal for locations with moderate-fiber-count cables (24 to 48 fibers) or if you're performing a mixture of backbone and fiber-to-the-desk projects. It is easily adaptable for high-fiber-count and low-fiber-count locations. The method is ideal if you have moderate labor costs and a reasonably stable, trained work force because it offers the maximum flexibility with one technology—and a good balance between material and labor costs.

Advantages of no-epoxy/polish connectors include lower material cost and a small capital investment.

- Setup: Essentially none; hand-held tools, no curing ovens to warm up, no stage required, and no consumables.

- Installation: Less than one minute per fiber, regardless of the number of terminations.

- Materials: Highest cost per connector kit, since some of the labor (polishing) is done in the factory, but likely to have the lowest labor cost. Some connectors require special tools, but the tools are usually hand-held and comparatively inexpensive.

- Skill: Minimal amount of training is required to learn the "strip, cleave, and lock" procedure; installations can more quickly utilize inexperienced labor. The no-epoxy/no-polish connector is ideal if you have a high turnover rate of technicians, or if you do a limited number of optical-fiber terminations.

Epoxy/polish connectors

There are two options for this technology: heat-cured, which requires 20 minutes or more in an oven, and quick-cure, which uses fast-setting epoxies like cyanoacrylates. Both are suitable for terminating high-fiber-count cables (more than 48 fibers) in a single location.

In these situations, the longer setup and curing time is offset by establishing an assembly-line type of process; while some connectors are being polished, others are in the curing process. Obviously, setting up a curing and polishing station at every work area is too cumbersome and time-consuming. The faster-curing adhesives considerably reduce the curing time, often to within two minutes, without the need for an oven and power source. But they are more expensive consumables and must be used quickly. These connectors are an excellent option if you have low labor costs and a stable, trained work force.

Advantages of epoxy/polish connectors include the lowest connector-kit cost, and the ability to offer the best performance (lowest loss, lowest reflections) if installed by skilled technicians.

- Setup: Takes approximately 10 minutes, because the adhesives and the polish station must be prepared before starting.

- Installation: Takes as long as 25 minutes for a single connector, but can be an average of 3 to 5 minutes each for a large number of connectors in a single location.

- Cost: The epoxy/polish connector has the lowest-cost connector kit, but requires a separate investment in a curing oven and polishing station. Additional consumables costs for the adhesives, fluids, and polishing papers must also be considered. For these reasons, the epoxy-polish connectors are economical if these costs can be spread across a large number of connectors.

- Skill: Although the technique is not difficult, it does require the most training, specifically in adhesive application and connector polishing. These skills take time to master and must be acquired to produce consistently good results. Accordingly, this technique is suitable if you have a trained work force, low turnover rates, and low labor costs. Due to the time required, high labor rates can impact the cost-effectiveness of this technology.

Pigtail fusion splicing

Rather than terminate the fiber in the field, some installers fusion-splice a pigtail (basically, one end of a patch cord) to the installed fibers. Worries about epoxies, hand tools, or curing times are eliminated; however, pigtail fusion splices requires the use of a fusion splicer to join the fiber in the pigtail to the installed fiber. Once the fusion splice is complete, you can install a factory-polished fiber connector.

Pigtail splicing makes the most sense if you've already invested in a fusion splicer. Installation can proceed quickly and the results can be as good as the epoxy-polish connectors. Today's compact fusion splicers are smaller and less expensive than previous-generation splicers, but still represent an investment of several thousand dollars. Renting can be economical, if for a few days or less. Since pigtails and patch cords are often mass-produced, the cost is slightly higher than the epoxy-polish connector kit, but doesn't require the assembly and termination labor. This technology works best if you're dealing with a large number of fibers.

Advantages of pigtail fusion splicing include low material cost, readily available parts, and good loss and reflection performance.

- Setup: Takes about five minutes at each location to set up the fusion splicer. A power source (or an extension cord to one) is usually required, although many fusion splicers have some inherent battery power.

- Installation: Takes about two minutes to prepare and fuse each fiber.

- Materials: The biggest cost is the capital and maintenance of the fusion splicer. Once this investment is made, however, each subsequent use reduces the net cost per termination. Each splice must be protected, either with a heat-shrink or sealant, and must be housed in separate trays. Both add to the materials and real estate (rack space) costs. Pigtails must be purchased separately, but are often available at low cost from several vendors. But keep in mind that the quality you pay for is the quality that is installed, so buy from reputable and traceable suppliers. This is a method with an extensive capital investment but minimal consumables cost.

- Skill: Using a fusion splicer takes training and skill, but modern fusion splicers make it easier to get good results once the fiber is loaded into the machine.

Herb Congdon IV, PE, is director of global marketing at Tyco Electronics/AMP Netconnect.