Cleaning Connectors: Manual vs. Automated Solutions for Fiber-Optic Networks

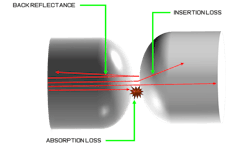

Fiber-optic technology has become the backbone of modern communication networks, enabling high-speed data transmission across vast distances with minimal signal loss. The efficiency of these networks, however, hinges on the performance of fiber-optic connectors. Contamination on the endfaces of these connectors can lead to significant signal loss, back reflection, and even permanent damage to the fiber, making the cleaning of these connectors a crucial aspect of fiber-optic network maintenance.

The Importance of Fiber-Optic Connector Cleaning

The performance of a fiber-optic network is highly dependent on the cleanliness of its connectors. Even microscopic particles of dust, oil, or other contaminants on the connector's endface can disrupt the transmission of light signals, resulting in increased insertion loss and return loss, which degrades the quality of the communication signal. Moreover, contaminants can cause scratches on the connector surface during the mating process, leading to permanent damage that necessitates costly replacements.

Cleaning fiber-optic connectors is therefore not just a matter of routine maintenance but a critical procedure for ensuring the best network performance and longevity. The cleaning process must be meticulous, effective, and repeatable to meet the stringent requirements of modern fiber-optic networks, particularly in high-density environments like data centers, telecommunication networks, and large-scale enterprise networks.

Manual Fiber-Optic Connector Cleaning

Manual Cleaning Tools and Methodologies

Manual cleaning of fiber-optic connectors has been the standard approach for many years and is widely practiced. The process typically involves using lint-free wipes, specialized cleaning tools, and engineered cleaning fluids to remove dust, oils, and other contaminants from the connector end faces. The most common tools and methods include the following.

Lint-Free Wipes: These wipes are used in conjunction with a cleaning solution or dry, with a gentle wiping motion across the connector endface.

Swabs or Sticks: Swabs or sticks are used to clean connectors within bulkheads or other confined spaces where larger tools cannot reach. They are ideal for highly contaminated connectors or for lower volume cleaning scenarios.

Click-to-Clean Tools: These tools are handheld devices that use a simple push mechanism to deploy a cleaning tape across the connector endface. They are designed for quick, effective cleaning of connectors in high-density cleaning environments.

Dry Cleaning: This involves using a tool, such as a wipe, click-to-clean tool or stick, in a wiping pushing or twisting motion to remove contaminants from the connector endface.

Wet-to-Dry Cleaning: In this method, a cleaning solution is applied to a lint-free wipe, stick or click-to-clean tool. The connector is then wiped from the wet area to a dry section of the wipe or tool to remove contaminants.

Advantages and Challenges of Manual Cleaning

Cost-Effectiveness: Manual cleaning tools and supplies are generally low-cost and readily available. This makes manual cleaning a cost-effective choice, particularly for smaller operations or in scenarios where automated cleaning equipment may not be justified.

Versatility: Manual cleaning can be applied to a wide range of fiber-optic connectors, regardless of size or type. Technicians can easily adapt their cleaning techniques to different connector types, making it a versatile solution.

Inconsistency: The quality of manual cleaning can vary significantly depending on the technician's skill, experience, and diligence. Inconsistent cleaning can result in residual contamination, leading to poor signal performance and increased risk of connector damage.

Time-Consuming: Manual cleaning can be a labor-intensive process, especially when dealing with a large number of connectors. The time needed for thorough cleaning can add up, leading to increased labor costs and potential delays in network maintenance or deployment.

Human Error: Manual cleaning is prone to human errors, such as improper use of cleaning tools, insufficient cleaning, or accidental contamination of the connector endface. These errors can compromise the effectiveness of the cleaning process and result in suboptimal connector performance.

Limited Effectiveness: While manual cleaning can effectively remove larger contaminants, it may struggle to eliminate smaller particles, oils, and other microscopic residues. This can lead to partial cleaning, leaving behind contaminants that can degrade signal quality.

Automated Fiber-Optic Connector Cleaning

Automated Cleaning Tools and Methodologies

Automated fiber-optic connector cleaning has emerged as a powerful solution to overcome the limitations of manual methods. These advanced devices are designed to deliver consistent and repeatable cleaning results with minimal human intervention. Touchless cleaners use a sophisticated combination of pressurized cleaning fluid and air to clean fiber-optic connectors without physical contact. A high-speed jet of air/fluid mixture adheres to the surface, effectively flushing contaminants from the endface and allowing them to evaporate away with the fluid. By avoiding direct contact, these devices reduce the risk of scratches and other damage while ensuring thorough and consistent cleaning.

Advantages and Challenges of Automated Cleaning

Full Endface Cleaning: Automated systems are engineered to tackle a broad spectrum of contaminants—such as dust, light oils, and residues—more efficiently than manual methods. Additionally, these devices clean the entire endface of the connector, extending to the ferrule edge. This thorough cleaning process leaves the connector spotless and dry, preventing any contamination from migrating back into the contact zone and disrupting the optical signal.

Reduced Risk of Damage: Reduced Risk of Damage: Automated cleaning devices are engineered to deliver precise pressure and controlled fluid flow, greatly reducing the risk of connector damage. This is particularly important for delicate or high-precision connectors, where manual cleaning could inadvertently cause harm. The touchless cleaning method employed by these devices eliminates physical contact with the connector endface, minimizing the risk of scratches and other forms of damage. Additionally, this approach reduces the likelihood of introducing new contaminants, making it an ideal solution for sensitive or fragile connectors that require a gentle and effective cleaning process.

Speed and Efficiency: Automated cleaning is significantly faster than manual cleaning, particularly when dealing with large volumes of connectors. Automated devices can clean a connector in just a few seconds, making them an ideal solution for high-volume cleaning tasks. The rapid cleaning cycle allows technicians to clean multiple connectors in a short amount of time, improving overall productivity, reducing labor costs and minimizing network downtime.

Enhanced Consistency and Precision: One of the key advantages of automated cleaning systems is their ability to provide consistently high-quality results. Automated devices apply a uniform cleaning technique with every use, ending the variability of manual cleaning and ensuring a reliable cleaning standard.

Initial Cost: The upfront investment needed for automated cleaning equipment can be significant, particularly for small organizations with limited budgets. The cost of buying and maintaining automated devices may be a barrier for some users. However, once the first investment in an automated cleaning system is made, the ongoing costs are significantly reduced to just fluid refills. This ends the need for continuous re-purchases of disposable click-to-clean tools or swabs which can also contribute to the amount of plastic waste sent to landfills.

Learning Curve: Although automated cleaners are user-friendly and intuitive to use, there may still be a learning curve for technicians who are new to automated cleaning devices. Proper training and familiarization with the device are needed for technicians to achieve consistent, high-quality cleaning results. However, once trained, automated cleaning devices can be used by a broad range of users from highly trained technicians to less experienced personnel.

Making the Right Choice For You

Fiber-optic connectors are vital to the performance and reliability of modern communication networks, where maintaining their cleanliness is essential for best signal quality and network efficiency.

Manual cleaning has long been the standard, offering cost-effectiveness and versatility. However, it is often plagued by inconsistencies, time consumption, and the risk of human error. While manual methods can be effective for smaller operations or less-demanding scenarios, they may fall short in terms of thoroughness and reliability, particularly in high-density environments.

On the other hand, automated cleaning systems address these limitations by providing a consistent, precise, and efficient cleaning solution. Automated systems excel in delivering uniform results, minimizing the risk of connector damage, and managing large volumes of connectors swiftly. The touchless technology further reduces the risk of introducing new contaminants, making automated systems particularly helpful for sensitive or high-precision connectors.

Although the first investment in automated cleaning equipment can be substantial, the long-term benefits are considerable. Once bought, the ongoing costs are limited to fluid refills, reducing the need for disposable cleaning tools and decreasing environmental waste. Additionally, while there is a learning curve associated with new technologies, automated systems are designed to be user-friendly, allowing for broad usability across varying levels of technician experience.

In summary, while manual cleaning methods still have their place, automated cleaning systems offer a compelling solution for organizations seeking efficiency, consistency, and environmental sustainability in their fiber optic maintenance practices. As technology continues to advance, the adoption of automated cleaning solutions is likely to become increasingly beneficial for supporting the high performance and reliability of fiber optic networks.

About the Author

Liam Taylor

Liam Taylor is European Business Manager, Fibre Optics at MicroCare UK Ltd and a member of IEC/SC 86B Working Group 4. MicroCare manufactures the Sticklers™ brand of specialist fibre cleaning tools. For more information, visit www.microcare.com.