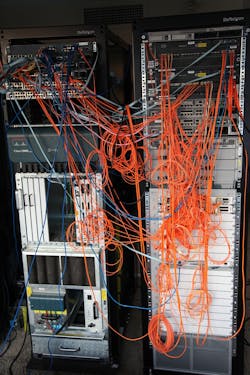

CABLExpress recently released its new "Fiber Optic Cabling Best Practices Guide," a set of guidelines "recommended pre-, post-, and during installation" of the company's Skinny-Trunk cabling products in accordance with the TIA-942 data center standard and based on its own field experience.

"These guidelines help improve operations by minimizing the risk of failure due to inadequate planning, mishandling of fiber cabling, improper testing, and reducing installation time," states CABLExpress.

The best practices tips encompass much general-purpose cabling installation knowledge. As a representative sampling, we've excerpted the top 15 guidelines with key quotes, as follows:

1. Do Port Mapping

"This map should include the cabinet placements, patch panels, hardware, port-counts, trunking locations and power access connection points...The design’s intent is to minimize future errors due to snags, awkward cable access, slack, and unprotected connections in trafficked areas. The design’s goal is to maximize efficiency using loss budgets productively."

2. Prepare for Fiber Cable Installation (A)

"Take inventory of all components received onsite to match to the bill of materials provided with the design...Make sure that you have all of the tools and materials you will need to complete your installation, including: Velcro and cable management, scissors to remove twist ties, a garbage bag for the packaging, a fiber cleaner (if needed), and cable labeling (if needed)."

3. Prepare for Fiber Cable Installation (B)

"Remove all product from the cardboard shipping containers before bringing them into your data center...Fibers from the cardboard packaging can become airborne and damage the hardware inside the data center."

4. Establish the Labeling Scheme

"Your label numbering scheme should match the TIA-606-C published standards for all jumpers and patch cords, labeled by: cabinet number; rack unit; port location; or labeling specified in scope...For longer lengths, label your trunk cables at both ends with length, origination, and destination information."

5. Determine Fiber Cable Breakout and Stagger Lengths

"Breakout lengths for your cables are the distance from the furcation point (where the individual cables separate from the consolidated, single sheathing) to the end of the connectors. These breakout lengths can be staggered to plug into specific ports, patch panels, and/or hardware."

6. Decide on Fiber Optic Service Loops

"Service loops are created when additional length is added to a cable for contingencies. If needed, short service loops (three to six feet) are helpful when trunk lengths are cut using estimated lengths. This overage allows the option to move patch panels or enclosures within the cabinet...The downside to service loops is the potential for too much congestion in the cable pathways...Whether service loops will be managed on the sides of a cabinet vertically or at a specific rack unit(s) horizontally is determined by the data center operator."

7. Be Careful of Cat6 Copper Service Loops

"It can be helpful to allow movement of patch panels inside the cabinet with service loops for both fiber and copper, if growth is expected. However, copper trunk service loops quickly can become unmanageable in typical server cabinets...Copper trunking is thicker and stiffer than fiber optic trunking. Copper also can have negative performance results from crosstalk when too many strands are bunched together in a bundle or tight space...If the cabinet is two feet wide and less than four feet deep, plan for minimal service loops, or no service loops at all."

8. Color Code the Cables

"TIA-606-C documents the official standards for cable colors. Beyond these, you can choose specific colors for your data center that define specific factors of your choice. But be consistent."

9. Manage Furcation Points

"When securing fiber trunk cables to enclosures, racks, or cabinets, only use zip ties on the trunks’ furcation points. The furcation point is designed for this, as it has a metal sleeve to protect the fiber...For all other applications use ONLY Velcro. Using zip ties on the fiber optic jacket directly can break the fibers."

10. Inspect/Clean the Fiber

"Before plugging into a port or patch panel, the installer must inspect the surface of the fiber optic glass end point (ferrule) with a microscope and, if needed, clean the connector with a one-click cleaner. Inspect a second time after cleaning before plugging in...Protective caps should be left on until immediately prior to cable installation."

11. Employ Cable Management

"When installing fiber optic jumper cables and copper patch cords from the patch panel to active ports within the same cabinet, use a combination of horizontal and vertical cable management to route cables from the left side of the patch panel to left side active ports, and the right side of the patch panel to right side active ports."

12. Don’t Bend, Kink, or Pinch Fiber Cables

13. Don’t Pull Too Hard

14. Conduct Post-Installation Testing

"Transmission performance depends on..cable characteristics; connecting hardware; patch cords; cross-connect wiring; total number of connections; proper care during installation and maintenance. Testing results directly after installation [should include]: continuity; shorts; transposed, reversed or split pairs, [and] grounded conductor."

15. Report Test Results

"Fiber-optic links should show the measured attenuation values, as well as the limits against which they have been tested, and the link length in a report or database. The testing documentation package should also include the following: date(s) of test; name(s) of test personnel; identification of field test instrument used, including manufacturer, model, and serial number, and date of most recent calibration of the test instrument. Test results should be provided both in soft and hard copy."

For more detail, we encourage you to check out the full "Fiber Optic Cabling Best Practices Guide", including supplemental graphs, as composed by CABLExpress.

You can also view/download the guide as a handy PDF document.