Why fiber network cleaning is essential to colocation space success

By Liam Taylor, MicroCare LLC

Colocation data centers provide flexible, scalable, high-performance fiber infrastructures that allow organizations to conveniently manage their network architecture. Thanks to their cost-effectiveness, high level of bandwidth, enhanced security and operational reliability, colocation spaces are increasing in popularity. In the last five years, the market size is estimated to have nearly doubled from USD 31.52 billion in 2017, to USD 62.30 billion in 2022 (source: Rack59.com). This growth has been spurred by the need for increased data due to the world’s appetite to be connected, the rollout of 5G technology and the pandemic, which triggered a surge in digital communication.

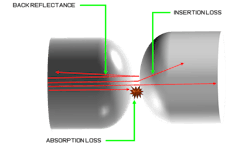

Although colocation data spaces are the practical solution to manage a business’s demand for rapid expansion and scalability, it also highlights the importance of ensuring the fiber networks used within them are robust and consistent. For modern optical networks to perform at their peak, the fiber network must be properly installed and maintained. This includes ensuring that all fiber connections and splices are kept perfectly clean to avoid potential problems such as insertion loss (weakened signal), back-reflection (the signal is diverted back to its source) or a complete system shutdown. Maintaining the fiber network, especially the connections, is crucial to the overall colocation network reliability.Whether using your own company’s technicians, or opting for a “remote-hands” approach as part of a technical support package from the colocation facility provider, managing fiber network maintenance and ensuring proper cleaning methods are in place is key to connectivity.

Manage the threat

The most common threat to any optical network is endface contamination; therefore ensuring the fiber network is clean and contaminant-free is essential. Even microscopic dust particles of just 1-micrometer on a singlemode core can block up to 1% of the light (a 0.05dB loss). A 9-micrometer speck is still too small to see without a microscope, but it can completely block the fiber core (source: Cisco). It is therefore essential to find a fiber endface cleaning method that is affordable, quick, consistent and effective. Using modern cleaning procedures ultimately saves time and money in troubleshooting, maintenance and repair, but most importantly, makes a network substantially more reliable.

Clean to IEC specifications

When setting up in a colocation space, or implementing long-term maintenance procedures, the same goal applies—to ensure all connectors are cleaned and inspected to meet International Electrotechnical Commission (IEC) 61300-3-35 standards.

IEC 61300-3-35 for the inspection and cleaning of fiber-optic connectors includes a list of requirements for fiber-optic connector endface quality. The guideline highlights specific cleanliness grading criteria to measure pass or fail certification during the inspection of a fiber endface before connection. Fiber technicians should understand this standard and use it as a reference tool to ensure all cleaning processes are precise and thorough. Even if a rented colocation space includes a maintenance package, it is important to make certain that the cleaning procedures used meet IEC 61300-3-35 to ensure your network is in safe hands.

Setting up a new network

Whether leasing colocation space by rack, cabinet or cage, it is still essential to clean all fiber splices and connections. Recent advancements in fiber-optic cable construction allow manufacturers to pack thousands more optical fibers into a single cable, increasing data transmission while saving on colocation space. As a result, these ultra-high-fiber-count (UHFC) cables that carry double or triple the data as comparably sized cables, at faster speeds, are gaining popularity. Typical fiber counts today can include up to 6,912 fibers. However, UHFCs and their end face connectors are typically more vulnerable than their predecessors to damage and contamination, making cleaning them more important.It would be wrong to assume that a new fiber cable assembly has a pristine connector endface free of contamination. Many molded plastic end-caps include chemicals called “plasticizers” to improve the durability of the end-cap. Unfortunately, these plasticizers outgas, leaving small oil droplets on the endface.

Many cable manufacturers also use mold release agents on the end-caps to speed up the manufacturing process. Often these end-caps retain some of the mold release agent on the inner surface, which can find its way onto the connector endface. Additionally, end-caps are never cleaned and frequently have small amounts of dust inside the sleeve, which can migrate onto the endface. To compound the problem further, there is the chance of wear debris contamination generated from taking the protective end-cap on and off. So, it is critical that endfaces, even brand-new ones direct from the factory, are thoroughly cleaned prior to installation.

Keep a clean space

The environment in which your fiber network sits can have a considerable impact on reliability. Although most colocation data center providers have policies in place to ensure cleanliness, it is important to check your space is being maintained regularly.

Even if the space appears to be spotless, dust-based contamination can also originate from boxes, packaging, clothing fiber, dead skin, plant pollen and vehicle emissions brought into the data center when entering. Dust particles can become embedded into the ferrule surface, resulting in pitted, scratched or scarred endfaces. Ensure installation and maintenance technicians are aware of the importance of working in an area as free of contaminants as possible.

The very tools used to keep a fiber network clean can also be the cause of contamination. Foam swabs and paper-based wipes that some installers use to clean the optical connectors can generate dust. Residue-based contamination can also come from substances like Isopropyl alcohol (IPA) when cleaning. Because IPA is hygroscopic, it absorbs moisture from the air and attracts airborne contamination; thus, rather than cleaning the fiber, technicians are simply worsening the problem by using contaminated fluid. Fiber technicians should opt for cleaning fluid, cleaning sticks and other cleaning tools engineered specifically for fiber cleaning. These specialty products will help ensure the network stays contaminant-free.

Maintenance planning for existing networks

Maintenance planning is essential when using a colocation space. Colocation providers can often be located a long distance from a business, making it challenging for a company to send technicians to work on a network if required to do so quickly. Ensuring you have the option of “remote hands” that can provide a reliable maintenance service is important.

Due to the precision required when maintaining a fiber-optic network, technicians must understand how to correctly handle and clean termini endfaces. We already know that through the use of insufficient cleaning tools, the contamination problem can be exasperated, so having the right cleaning equipment is essential. Companies should plan ahead to ensure they stock the correct type and sufficient quantity of the splice and endface cleaning products needed to complete an installation.

Fiber-optic cleaning kits are an excellent resource to ensure cleaning fluids and tools are always at the ready. The kits should comprise high-purity cleaning fluids, optical-grade wipes, lint-free cleaning sticks and push-to-click tools. Another important point to make here is that the kit should be travel-safe. Because colocation spaces can be miles from a company headquarters, it is important that technicians can travel easily with their kits. If pre-shipping fluids and tools to the facility, choose a fiber cleaning fluid that is non-flammable and can be shipped under non-hazardous and non-regulated policies to reduce shipping costs. Some fiber cleaning fluids come in travel-sized containers, making it easy for installers to meet the TSA 3-oz.-or-less rule if they carry it in their bag when flying to a work site.

Cleaning fluid should also come in a hermetically sealed container. A sealed container ensures the cleaning fluid is never contaminated and won’t spill when placed in a kit—another important consideration if traveling.

Follow the rules

If there is one critical point to remember when installing and maintaining fiber it is to always clean-inspect-clean both ends of a connector pair before mating. This ensures perfectly clean fiber connections every time to guarantee the network runs efficiently.

Here is a short list of the main cleaning procedures that should take place without exception.

1) Before you start, wipe down your work surface and tools with a general purpose presaturated wipe to remove any contaminant. Don’t forget to also clean any inspection equipment. Connectors and ports on test equipment are mated regularly and are highly likely to become contaminated. Clean all equipment to stop any cross-contamination and ensure testing is accurate. Wash hands thoroughly to remove any dirt and oils that can compromise the cleaning process.

2) Next, inspect. it is important to understand what the contamination is and how to remove it successfully. For example, optical-grade wipes are good for wiping fiber end splices and for lighter cleaning of widely spaced male-end LC connectors. Mechanical push-to-click tools or specially engineered fiber cleaning sticks are preferred when cleaning very dirty connectors and for getting into tight-pitched CS adapters.

For high fiber counts, which are typical in a colocation space, a push-to-click tool is popular as its convenient and quick to use. Push-to-click tools are built for high-capacity applications and are a good option for medium contamination.

Always use a wet/dry cleaning method to reduce static, which can compound the contamination problem. Dampen the tool with an ultra-pure static-dissipative cleaning fluid before cleaning to remove both contamination and static charge with ease.3) It is extremely important to inspect each endface after cleaning and before mating to ensure any contamination is removed. If it is not removed it will cause cross-contamination of both endfaces, disrupting the optical signal path. Ensure that all connectors are contaminant-free and inspected to meet IEC 61300-3-35 standards. If the endface is still contaminated, re-clean using the clean-inspect-clean process until the endface is clean after inspection.

Futureproofing your fiber network

Adding capacity on-demand and scaling networks quickly are important to companies as the requirement for faster connectivity and more bandwidth grows. This has fueled the growth of colocation data centers, which can allow businesses to cost-effectively grow their networks.

With the widespread adoption of colocation data centers, fiber contamination and efficient fiber cleaning has become a significant consideration. For consistent trouble-free fiber-optic networks, cleaning must be a priority.

If using a remote hands service, find out if your colocation provider has the knowledge and credentials to effectively maintain your fiber. If using your own technicians, ensure they have the expertise in cleaning techniques and how to meet IEC standards. Also invest in the correct tools so all installation and cleaning procedures can be done effectively the first time to optimize their time and cost-effectiveness.

With the proper planning and preparation in place, a colocation space can be an effective solution to increasing reliable connectivity and futureproofing your network.

Liam Taylor is European business manager, fiber optics, at Microcare, LLC. He is a member of the IES/SC 86B Working Group 4. MicroCare, LLC manufactures the Sticklers brand of specialist fiber cleaning tools.