Belden’s 10GXS Cat 6A cable awarded ‘Most Innovative AV Installation Accessory’ at InfoComm 2016

Belden announced that its 10GXS Category 6A cable received the “Most Innovative AV Installation Accessory” award, presented by Systems Contractor News (SCN) at InfoComm 2016 (June 4-10) in Las Vegas. The awards program showcased innovative commercial AV products.

Belden says its 10GXS Category 6A smaller-diameter cables reduce space and weight up to 25 percent without sacrificing performance or quality. “Exceeding industry standards, 10GXS cables offer 75 percent less noise coupling than other Category 6A cables,” notes a product press release from the company. With the company’s Equiblock barrier providing uniform heat-flow dissipation, the 10GXS cable can support 100 watts of PoH/PoE+ up to 100 meters without signal degradation. Its smaller size and bend radius accommodate tight spaces and smaller conduits. Easy-to-remove barrier tape accelerates installation.

The company adds, “Belden 10GXS addresses HDBaseT’s biggest challenge-alien crosstalk-by offering a patented EquiSpline that controls the balance of the cable by providing a compartment for each pair. These compartments ensure consistent cable geometry, which enables higher performance in terms of noise rejection and insertion loss. This provides excellent alien crosstalk isolation in an environment where cables are tightly bundled. The pairs are very well balanced, and the system is not affected by ground loops that can cause interference and transmission errors in shielded systems. It optimizes electrical performance with up to 10 dB of alien crosstalk headroom and offers superior crosstalk isolation and EMI suppression.”

In addition to its non-bonded 10GXS cable, Belden notes that it now also offers the 10GXS in bonded-pair construction. Belden says its bonded-pair cables “feature a patented design that bonds the individual conductors along their longitudinal axis to guarantee extremely uniform spacing within each twisted pair-a key factor in maintaining consistent electrical performance.”

CommScope showcases data center infrastructure, intelligent buildings at Cisco Live 2016

CommScope demonstrated its latest data center infrastructure and intelligent building solutions at Cisco Live 2016, held July 10-14 in Las Vegas.

In its booth at the Mandalay Bay Convention Center, CommScope experts showcased network solutions for connecting users to meet future bandwidth requirements, connecting and powering network devices, and managing the physical infrastructure more efficiently. The company’s cabling experts also hosted demonstrations of multi-gigabit NBase-T signaling on Ethernet cabling, a technique for boosting transmission speeds in a cost-effective, minimally disruptive manner.

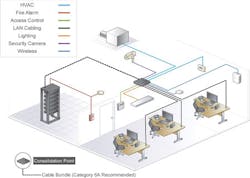

Additionally, CommScope’s intelligent building experts were also present in the event’s Digital Ceiling Pavilion to demonstrate the company’s Universal Connectivity Grid (UCG) solutions, including its Systimax GigaSpeed X10D Category 6A cabling and imVision Automated Infrastructure Management (AIM) platform. The UCG is CommScope’s common connectivity platform designed to deliver high bandwidth and remote powering capabilities in support of intelligent building applications, accelerating the convergence of connected lighting sensors, gateways, building controls and analytics over a Power over Ethernet (PoE) infrastructure to unleash the power of IoT in buildings.

“Data centers are changing quickly with many organizations choosing co-location facilities and the cloud for analyzing and processing data with on-demand access. Buildings are evolving rapidly because of technology advances in connecting people and machines in the Internet of Things and new capabilities for space utilization and energy efficiency,” said Dr. Ispran Kandasamy, global leader, Enterprise Building Solutions, CommScope. “With our wide range of fiber and copper solutions for wired and wireless networks, CommScope is ready to help IT departments build connected and efficient data centers and buildings.”

NEC breaks spectral efficiency record over single optical fiber, close to Shannon limit

NEC Corporation in June announced that it has demonstrated a transmission capacity of 34.9 terabits per second (Tbit/s) on a single optical fiber, over a distance greater than 6,300 km. This achievement breaks the spectral efficiency record for transoceanic transmission*, achieving 8.3 bit/s/Hz using the C-band spectrum. This is a 16.9 percent improvement on the previous record, contends the company.

“These results come very close to the Shannon limit, the fundamental spectral efficiency limit of optical communications,” said an NEC press release. “Maximizing spectral efficiency is one of the primary goals in the design of submarine cable networks, enabling the highest possible capacity per fiber pair, while reducing the terminal equipment cost, space and energy consumption. This demonstration of NEC’s technologies comes within 0.5 decibels (dB) of the theoretical maximum value.”

“We are proud to have come so close to Shannon’s cornerstone of communication theory,” said Toru Kawauchi, general manager of the submarine network division at NEC Corporation. “NEC’s research and development teams will continue to explore the limits of even greater subsea capacity, flexibility, and cost-effectiveness.”

The research results were recently presented at the post-deadline session of the Optical Fiber Communication Conference and Exhibition (OFC) 2016 in Anaheim, California.

*According to research by NEC. The previous world record was 7.1 bit/s/Hz.

Workshop focuses on hiring military veterans in cable and telecommunications industry

On July 13, the Cable and Telecommunications Human Resources Association (CTHRA) and the National Cable and Telecommunications Association (NCTA) sponsored a workshop titled Heroes Work Here, which educated industry employers on hiring and retaining United States military veterans. Mission Media and the Disney Institute hosted the event. The CTHRA said the workshop drew 150 attendees from across the cable and media industry.

The program focused on how to target, recruit, engage, develop and retain military veterans in the industry, the CTHRA added. “Targeted for human resources professionals and others responsible for and passionate about veteran hiring, attendees had the opportunity to learn from and network with national thought leaders from industry employers, government agencies and veteran support organizations,” the association said.

Retired U.S. Army Brigadier General and current vice president of military and veterans affairs for Comcast, Carol Eggert, moderated a panel titled “Transitioning from Military to Civilian Careers in Cable and Media." Keynote speakers were Jeffrey Horne, chief executive officer of IVET and a retired U.S. Army Brigadier General; as well as Wes Moore, a U.S. Army combat veteran, author, and host of “Beyond Belief,” which airs on the Oprah Winfrey Network.

Pictured left to right are Wes Moore, author and host of “Beyond Belief,” keynoter; Yamil Cedeno, network operations center technician, Charter Communications; Jon Dorsey, associate producer, Discovery Communications Emerging Networks; Carol Eggert, vice president of military and veterans affairs, Comcast; Michael B. Smith, solutions specialist, Cox Communications.

Mission Media was founded in fall 2015 by the cable and entertainment industry. It is described as a systematic, industry-level approach to the hiring and retention of veterans. The program was developed by the industry’s 22-member Veterans Advisory Council under the honorary chairmanship of NCTA president and chief executive officer Michael Powell. Mission Media is managed by the CTHRA.

Wastewater treatment plant used to cool Apple’s Oregon data centers

As recently noted by local news media outlet The Oregonian / Oregon Live, “Apple, known for its polished smartphones and antiseptic stores, is getting into the wastewater business” when it comes to cooling its data centers in the state.

“The company confirmed...that it has agreed to pay for a treatment facility to re-use water for evaporative cooling in its Prineville data centers,” wrote The Oregonian’s Mike Rogoway in a June report. “By recycling water for Apple instead of taking it straight from the tap, the city says its new facility will save nearly 5 million gallons a year.”

The report adds, “The recycled water will come from the city’s regular sewage treatment system, water that would otherwise have been less rigorously treated before being used at the city’s golf course or flow to pasture lands or into the Crooked River. The city says it has other water rights that provide adequate supplies for those other purposes. Apple is already Prineville’s top water user, gulping down 27 million gallons of water in the last year, according to city estimates.”

The company has a massive, 338,000-square-foot data center on the bluff above town, adds the reporting, which includes some modular facilities; it is also seen building a second, large-scale building. “[Apple] owns 200 more acres nearby with capacity for considerable expansion,” adds Rogoway. “Prineville said Apple’s ongoing construction inflated last year’s water consumption, but neither the city nor the company would provide forecasts of how much water the data centers themselves use.”

Pinacl opens office in London’s Canary Wharf

Pinacl, a U.K.-based provider of network infrastructure, services and wireless technologies, recently opened an office in the heart of London’s Canary Wharf financial district. “This move is in conjunction with our continued investment, which enables us to respond to the growing needs of our customers and work closely with vendors. Additionally, it accelerates our desire to pursue prospects in line with our strategic growth plan,” the company said.

The new space is in the 1 Canada Square building, which Pinacl characterized as “an iconic part of the London skyline.

Liam Wynne, the company’s global account director, commented, “Our international clients often procure centrally out of London, hence with Pinacl now being part of Canary Wharf, it allows us to be more effective in responding to the needs of our customer base. It also affords us the opportunity to expand our core solutions into the city, with the new office location reinforcing our commitment to strategic growth. This is a very exciting time for Pinacl and I am very pleased to be involved in spearheading this development and growth of our services into the marketplace.”

Pinacl’s board of directors and several of the company’s clients and vendors were present for the office’s official opening on August 8.

Rob Bardwell, the company’s managing director, added, “Pinacl are in an exciting growth period post the management buyout successfully accomplished a year ago. Now focusing on growth markets by delivering ICT solutions in a way that allows our customers to enjoy new opportunities within their businesses and not be restricted by its delivery. This presence in London puts us at the heart of one of our key customer markets.”

According to its website, Pinacl offers managed services, managed wireless, and managed network infrastructure incorporating LAN, WAN and public and private WiFi.

Brother’s LabelLink streamlines cable labeling using Fluke Networks’ LinkWare Live

Brother Mobile Solutions recently announced it has formed a relationship with Fluke Networks, through which Brother has licensed the LinkWare Live API to create LabelLink, a mobile app and back-end solution “designed to dramatically streamline the network and cable labeling process,” Brother Mobile Solutions said.

“Built on Fluke Networks’ LinkWare Live platform, the new solution leverages the latest developments in cabling certification testing technology and advanced mobile printing capabilities to deliver unprecedented speed, efficiency and accuracy to the cable ID and labeling process-a discipline which continues to grow in scope, complexity and urgency as data centers evolve,” Brother added. “Electrical construction and engineering contractors can now meet multiple project needs for cable ID by inputting data only once.”

Here’s how Brother Mobile Solutions describes the process of using the LabelLink solution.

In the office, the system designer uses CAD to plan the network infrastructure, and then uploads cable ID and component identifiers to LinkWare Live, Fluke Networks Cabling Certification tester and report management application.

Contractor downloads and installs free LabelLink app.

On the jobsite, the contractor or technician downloads the identifiers from LinkWare Live through a smartphone into a Brother P-Touch EDGE PT-E550W industrial labeling tool, which is used to create and print high-quality, standards-compliant laminated labels.

On the jobsite, the contractor also downloads the same identifiers into the Fluke Networks Versiv Cabling Certification System, performs the tests, and uploads testing results for each identifier using LinkWare Live.

In essence, the LabelLink solution allows the cable identifiers and test results for each project to be stored in one place and to be retrieved and used as many times as needed, contends the company. “Keeping track of cable identifiers across multiple databases for testers and printers wastes time and cuts into our profitability,” commented CJ Santeford, operations manager of PowerCom, a Bothell, WA-based installer of communications infrastructure. “Brother’s LabelLink app combined with LinkWare Live gives us the ability to use a single database for managing this important task.”

According to David Crist, president of Brother Mobile Solutions, “This solution was created by two great brands combining their technologies to make network wire, cable and component testing and labeling faster and easier than ever before. It’s a real game-changer, especially for contractors engaged in standards-based labeling of large and complex datacom installations. Our Brother Mobile team is thrilled and excited to work with Fluke Networks to introduce the LabelLink application to the world.”

Eric Conley, vice president and general manager of Fluke Networks, added, “LinkWare Live bridges the gap between the project manager’s office where the data for testing cables and printing labels originates, and the jobsite where Fluke Networks testers and Brother labeling tools are used by the installation crew. For network designers, integrators and contractors, the combination of Versiv, LinkWare Live, and the LabelLink app automates multiple workflow processes and will help eliminate a major pain point in jobsite productivity. More importantly, it ensures labeling accuracy across the entire project.”

“Brother created an app for our EDGE label printer that interacts seamlessly with the cloud ID data file, so installation workers can instantly access the relevant cable identifier and create and print labels without the need for additional data entry,” said Duane Yamashita, senior product manager for Brother’s P-Touch EDGE industrial labeling brand. “This not only ensures accuracy and consistency of the network labeling scheme as designed and built, but also provides the foundation for an effective cable management program going forward.”

The Brother P-Touch EDGE PT-E550W features wireless connectivity for transferring data and printing directly from mobile devices. It can print labels up to 24mm wide, including heat-shrink tube, and Brother says it is ideal for labeling large, complex IT network projects.

Fluke Networks added that this agreement between itself and Brother Mobile Solutions “highlights extended benefits of the LinkWare Live platform for cable installers.” The company said the agreement “makes the network and cable labeling process more efficient by allowing technicians to print cable and ID labels on the jobsite using data generated during the design and installation stages. The Brother LabelLink app enables cable installers to achieve greater efficiencies, improved accuracy and profitability by entering data a single time for reuse in the labeling phase of the cable installation process.”

Conley added, “The relationship with Brother is a model for this type of technology integration partners Fluke Networks is working to identify. There are other companies who have applications and services that make sense to integrate with Fluke Networks’ technology that will ultimately benefit our customers’ business and the jobs they do.

“Today’s cable installation projects are larger and more complex, and demands facing network designers and installers are more rigorous than they were only a few years ago. When we initially conceived of LinkWare Live in 2014, we realized that it would establish a powerful and flexible infrastructure for our customers and provide Fluke Networks a way to efficiently update our tools and capabilities. Now we have a greater understanding about how other vendors can leverage the platform to improve the capabilities of their tools as well.”

Take a virtual tour of CyrusOne’s 172,000 sq. ft. Austin III data center

Following the recent completion of its Austin III data center, CyrusOne is giving internet audiences a glimpse into the design of the facility through the company’s latest virtual tour video. The video is now available online at CyrusOne’s website and YouTube channel.

Centrally located, the colocation provider’s Austin III data center is housed in the Met Center, Austin’s premier mixed-use business park. The facility encompasses 172,000 square feet and features stringent physical security, redundant utility power feeds, and exceptional connectivity solutions, says CyrusOne. It also features advanced cooling infrastructure and, at full build, will offer 120,000 colocation square feet and up to 18 megawatts of power. As part of CyrusOne’s National Internet Exchange (IX) platform, Austin III can also provide interconnection to other CyrusOne data centers in Texas and multiple other markets across the country.

“Designed and built with the latest features and amenities, the Austin III data center provides enterprise-class service and capabilities to meet the rapidly growing demand of our customers in the Austin market,” said Scott Brueggeman, chief marketing officer, CyrusOne. “The new Austin III virtual tour highlights the facility’s design, systems, amenities, and security features, which make the CyrusOne Austin campus ideal for production and disaster recovery server environments for national, international, and local companies.”

View the virtual tour at: http://www.cyrusone.com/data-center-location/texas/austin-texas-met-center-iii/

Prefab metal cable tray features ventilated or solid bottoms

Cope, a specialist in cable management solutions, now offers the Cope Trof cable tray system, a pre-fabricated metal structure featuring ventilated or solid bottoms welded to side rails. Designed for most size cables, the Cope Trof cable tray is available in hot-dip galvanized steel, pre-galvanized steel, stainless steel, and aluminum versions. The range of materials is intended for customization to all environments. Cope says the Trof cable tray is ideal for use in the power, automotive, transportation, service entranceway, data, heavy industrial, commercial industries applications.

Manufactured and tested to NEMA standard VE-1, the Cope Trof cable tray features corrugations that provide great lateral rigidity to the bottom of the tray, transmitting the load to the side rails. Offering continuous support of one inch ribs every two inches, with or without ventilation, the tray’s design virtually eliminates cable sag and uneven cable point loading, claims the company. The bottom design offers safety and security from unauthorized access. The tray system’s ventilation allows for free passage of air through the openings, resulting in a 68 percent open area to facilitate proper heat dissipation.

The Cope Trof cable tray meets ASTM A1011 or ASTM A1008 standards for hot-dip galvanized steel products; ASTM A-653-G90 for pre-galvanized steel products; AA-6063-T6 and AA-6063-H34 for aluminum side rails and bedplates, respectively; and ASTM A-240 type 304 for stainless steel products. A comprehensive range of fittings makes the system customizable to accommodate varying configurations. Users can achieve design flexibility with numerous sizes of horizontal and vertical elbows, adjustable elbows, cross pieces, tees, reducers and branches. Cope’s customer service experts can help customers select the right fittings for specific applications.

Siemon launches comprehensive data center aisle containment line

Siemon recently announced an expansion of its line of WheelHouse Advanced Data Center Solutions to include comprehensive aisle containment systems with both cold aisle containment (CAC) and hot aisle containment (HAC) options. The company contends that the new product options can significantly improve efficiency and cost-effectively expand capacity for today’s data centers.

“By either containing and isolating the cold air supply (CAC), or by guiding hot exhaust to overhead return air spaces (HAC), Siemon’s Aisle Containment Solutions prevent the mixing of hot and cold air in the data center,” said a company press release. “This allows for higher temperature return air to improve the efficiency of existing cooling systems and reduce energy costs, while preventing over-provisioning of computer room air conditioning (CRAC) units. Alternatively, these solutions cost-effectively expand the capacity of the data center to cool higher heat densities, maximizing both cabinet and data center floor space without the need for supplemental cooling.”

Designed with robust seals for optimal thermal isolation, Siemon’s new Aisle Containment Solutions product line consists of CAC roof panels, HAC vertical standing and end panels, single and double manual and self-closing doors, and end panels that have been designed for quick and easy on-site attachment to rows of Siemon VersaPOD, V800 and V600 data center cabinets. The containment systems are also compatible with Siemon’s SidePOD and Baffle solutions that support side-to-side ventilated active equipment. A range of accessories are also available to complement the system, including filler panels to fill spaces where cabinets are not present, wall mount brackets for installation against a wall for a single cabinet row, angled support brackets to provide lateral support to vertical panels when attaching to the ceiling is not feasible, and riser brackets to increase clearance within the contained aisle when using shorter (42U) cabinets.

“Hotter return air temperatures facilitate heat exchange within cooling systems, improving power usage effectiveness (PUE) and reducing energy costs through lower fan speeds, higher chilled water temperatures and greater economizer hours while sufficiently cooling data center equipment to maximize performance and life expectancy,” adds Stuart Gray, product manager at Siemon. “For both new and retrofit situations, aisle containment systems are an economical way to prevent costly oversupply of cold air while enabling growth in data center environments - whether using cold aisle containment for a raised floor environment with no overhead return air space or hot aisle containment to maintain an overall cooler working environment outside of the contained area.”

Nest ‘re-invents’ outdoor security cameras

Nest Labs, Inc. recently announced sweeping changes to its security camera portfolio with the introduction of its Nest Cam outdoor security camera, as well as additional features to its Nest Aware service, and a new way to interact with the entire range of Nest products through the Nest mobile app. A synopsis of the new offerings, according to the company, is as follows.

Nest Cam Outdoor: With a brand new, completely weatherproof industrial design created for permanent outdoor use, Nest Cam Outdoor extends security outside the home. Customers can keep an eye on their homes 24/7 with full high-definition (1080p) video quality anytime, anywhere and in any weather. Customers also get all the features of Nest Cam Indoor, including activity alerts and Talk and Listen.

Person alerts: Subscribers to the Nest Aware service will receive person alerts, allowing Nest Cam to distinguish between a person and another activity and let you know when someone comes into view. Person alerts are the first of a new generation of intelligent alerts from Nest that leverage Google’s expertise in machine learning and algorithms to deliver deeper insights to customers about what’s happening at home. Nest Aware features including person alerts are available on all Nest Cam and Dropcam cameras.

New Nest app: The redesigned Nest app delivers new software features and makes existing Nest products better, including earlier versions of Nest Cam. With the introduction of Spaces, the Nest app delivers a brand new user interface that groups Nest products by room, across multiple platforms, making it easier to access and control Nest products.

“Nest is completely reimagining the camera experience with new hardware, a redesigned app, and more intelligent alerts. And because Nest is constantly improving its products, current Nest Cam Indoor and Dropcam customers will also benefit from these new features,” comments Maxime Veron, director of hardware product marketing for Nest. “Nest Cam provides customers with peace of mind and the ability to stay connected to the things they care most about. Now, Nest Cam Outdoor brings thoughtful security outside of customers’ homes, helping them secure their property and giving them more ways to watch over their families, even when they’re miles away.”

Nest Cam Outdoor is available now for pre-order in the U.S. and Canada at nest.com, bestbuy.com, and bestbuy.ca with a suggested retail price of $199, same as Nest Cam Indoor.

It will be on shelves this fall.

Multi-packs will be available later this year.

New Category 8 plug has integral circuit board technology

Optical Cable Corporation (OCC) announced that it is introducing a new Category 8 RJ45 plug with integral circuit board technology that provides advanced control of crosstalk, return loss and other impediments, “ensuring consistent performance at higher frequencies up to 2000 MHz.”

The company continued, “Category 8 Ethernet cable will play a major role in meeting today’s burgeoning needs for high-speed communications, whether in the data center, voice, video or other high-bandwidth applications that run on copper cable for distances up to 30 meters.”

Derrick Stikeleather, OCC’s copper connectivity manager and a member of the TIA TR-42.7 Engineering Subcommittee, commented, “Essentially, the new plug contains technology that provides advanced control of plug performance. In a conventional category style plug, the plug wires must be arranged in specific positions, leading to variations in performance. But when a circuit board is used, it basically eliminates the possibility of plug wire variations. It also means that electrical properties transition from a cable to a terminal in a more controlled fashion.”

He added that the new, proprietary technology uses a higher-performance type of circuit board material than what is contained in a standard connector. “Without this, achieving quality data transmission rates of 40 Gbits/sec would not be possible.”

This new plug was recently granted a patent, OCC announced, for circuit board layout and the advanced materials used in its construction. The company says the Category 8 plug is ideal for direct-attach, high-speed links and data center server connections.

In 2014, OCC announced the commercial availability of a field-terminable plug that met the then-current draft of Category 8 specifications.

About the newly patented plug, Stikeleather said it provides consistent and reliable terminations that are guaranteed to meet or exceed Category 8 standard specifications when paired with compliant Category 8 cable. The new RJ45 plug is fully backward-compatible with existing RJ45 infrastructure used by a majority of Ethernet connection ports, including Category 6A, Category 6 and Category 5e. It is field-installable. OCC adds that the new plug also is compatible with its family of ruggedized RJ45 connectors, a family of receptacles, plugs, and back shells that enabled users to extend their Ethernet platforms into harsh industrial and military operating environments.

Report: 84 percent of IoT data comes from data center equipment

The vast majority of IoT data derives from data centers, claims a new analyst report.

Even though they may not be familiar with the term “Internet of Things” (IoT), 65 percent of organizations are collecting data from equipment, devices, or other connected endpoints. And they’re using that data for business purposes, according to an IoT study conducted by 451 Research.

The study finds that the vast majority of IoT data derives from data centers. The research indicates that more than half of IoT data (51 percent) is coming through data center IT equipment, followed by camera/surveillance equipment (34 percent), data center facilities equipment (33 percent), and smartphones (29 percent).

The types of data being collected are broken down into three categories: machine sensing (data gathered from machines), biological sensing (data gathered from humans and animals), and environmental sensing (data gathered from the environment). The majority of the data today is gathered from machines for business use (71.5 percent), while data gathered from humans and animals (8.5 percent) and the environment (20 percent) represents a smaller, but growing portion of the overall data.

The type of industries predominantly using IoT platforms today are evenly split between manufacturing organizations collecting data from factory equipment and healthcare organizations from medical devices, adds the study. “Not surprisingly, 46 percent of the study’s respondents showed concern with IoT security, and nearly a third of respondents said that lack of internal skill sets was their biggest issue,” added the analyst. “These are followed by lack of IT capacity and lack of perceived ROI/benefits.”

Comtran Cable credits women in key roles for ongoing success

Comtran Cable recently publicized the fact that women in sales, marketing, engineering and materials roles represent 42 percent of the company’s non-manufacturing staff. “This is well above average for wholesale and manufacturing industries,” the company pointed out. “According to the U.S. Bureau of Labor Statistics, in 2015 women comprised about 14 percent of engineering, 26 percent of sales, and 44 percent of purchasing in similar occupations. The good news is that these numbers are significantly higher than 20 years ago.”

The company added that executives did not specifically set out to hire women, but are seeing the positive impact of the hiring decisions they have made. “In every case we hired the most qualified person,” said Joe Barry, general manager. “As luck would have it, we ended up with our own dream team of talented women … and the company is doing better than ever.”

“Being the only woman at the table can have its challenges, but times are changing,” Comtran Cable stated. “More and more, women are considered equals.”

In a statement, Comtran detailed the professional backgrounds as well as current responsibilities and achievements of several women in its employ.

Paulette Blagburn spends her workdays at the R&D bench, solving cable design problems and creating new products. Karen Credit manages purchasing, planning and inventory control. Kathy Beaudoin leads the sales team in landing new accounts and closing deals in a highly competitive market. “These three are part of a group of women playing key roles at Comtran,” the company said. “Their presence in the largely male-dominated cable world is part of a ‘dream team’ credited with Comtran’s ongoing growth and success.”

Their career paths are as varied as their current jobs, the company added. Some are just beginning their careers; others are 20-year veterans of wire and cable. “I was entrepreneurial from the time I could count change and work my grandparents’ vegetable stand,” recalled Danielle Braley, Comtran’s Midwest regional sales manager. “I started at Draka working for the VP of engineering 20 years ago, and rose up through the ranks. I was fortunate to have some amazing mentors along the way.”

Paulette Blagburn, product design engineer, has been at Comtran for one year. She works primarily on new and existing fire-resistive and rail-transit specialty cable products. She acknowledges that when she was in high school, girls were not encouraged to pursue STEM (Science, Technology, Engineering, Mathematics) careers the way they are today. Blagburn was drawn to electronics when she started installing and terminating networks for the City of Woonsocket, RI. She said she has not encountered discrimination in her career, and also credits male mentors for contributing to her success. On the topic of job satisfaction at Comtran, Blagburn commented, “My products contribute to saving lives. How awesome is that?”

Tracy Pajala, inside sales account manager, shared her perspective on how to thrive when colleagues primarily are men: “Being a woman, you tend to get more attention focused on you in a male-dominated industry. The challenge is keeping that attention positive and professional. Having a good sense of humor and not being easily offended helps immensely.”

Other women on Comtran’s team include Kristen Davenport, inside sales account manager and Brianna Cote, marketing coordinator. Davenport’s clients benefit from her degrees in economics and marketing, which help her position and market Comtran products to meet current economics of the cable industry. Cote joined Comtran 3.5 years ago after earning her marketing degree. As a millennial, she is fluent in social media and digital marketing, which have helped Comtran gain industry exposure and qualified leads.

Pictured on this page are the women in Comtran’s “Dream Team” (left to right): Donna Fitzgerald, Danielle Braley, Tracey Pajala, Kristen Davenport, Kathy Beaudoin, Karen Credit, Brianna Cote, Paulette Blagburn.

Android app controls Greenlee’s DataScout Ethernet tester

Greenlee Communications now offers an Android application that enables remote control of the company’s DataScout multi-service network analyzer. “This new Bluetooth interface and app option enables the device to be remote controlled up to 100 feet away using any Android tablet or mobile device equipped with Bluetooth,” said a company press release. “The DataScout can also be locally controlled via the built-in ruggedized LCD touch screen in addition to WAN remote control via a web browser.”

The DataScout tester integrates eight independent test options including dual-port 1G and 10G Ethernet, T3/E3, T1/E1, DS0, PRI-ISDN, 2W/4W Signaling-TIMA, DATACOM and DDS. “Service providers and utilities are integrating mobile devices into their workflow and seeking test equipment leveraging these devices,” said Ken Fridley, product manager for the Greenlee Communications branded products. “The DataScout mobile application enables technicians to work independently of their test equipment, yet still retain touch-screen command and control when working at the device.”

Fridley added, “Technicians traditionally expect to have a touch-screen display embedded in their test device but also enjoy freedom of movement provided by mobile device control. By integrating Bluetooth technology into the DataScout 10G, technicians now have the best of all worlds. Our Bluetooth and LAN remote management options enable both onsite and remote technicians to perform testing virtually anywhere Bluetooth or network connections are available. This enhances safety by allowing techs to step out of noisy or cramped work locations as well. As former technicians and managers ourselves, the engineering team and I enjoy getting into the field with customers to design quality test solutions with the right combination of features required to get services provisioned quickly and confidently. The DataScout multi-service network analyzer is built by technicians, for technicians.”