Versatile tool solves for small-conduit FTTx patch cord pulls

PulR Technologies recently announced its signing of a lease with IDETR [Innovation et Développement économique Trois-Rivières], Quebec's economic development agency, and has now established its headquarters at the Novocis building, located at 1300 Place du Technoparc, in Trois-Ricivieres, QC, Canada.

PulR is the trademarked brand name owned by 13447685 Canada Inc., which stands behind a new concept for pulling fiber-optic patch cord cable adapters.

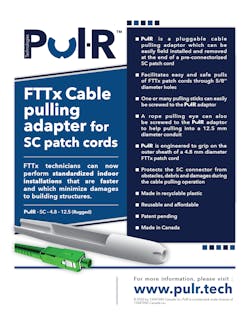

The PulR tool is intended to solve the challenges faced by cable installation technicians when pulling patch cords through walls, conduits, floors, overhead ceilings, behind baseboards, etc.

The tool handles telecommunications cabling patch cords that are pre-connectorized on one end or both ends. Connectors handled by the PulR include SC, LC, MTP, SN, and others.

The company states the invention's value proposition thusly, noting how:

"Patch cords are of a set length proper for a given installation, such as 5, 10, 15, 20 or 30 meters, etc. The expectation is that it will be more economical to make use of patch cords than than field terminating with a fusion splice-on or mechanical connector.

The most widely used patch cord for FTTx is based on a ruggedized sheath with a diameter of 4.8 mm. This patch cord type can withstand being stapled and mishandled. It is known as a bend insensitive self-bend limiting patch cords,and it usually has SC/APC connectors on both ends. It is known as self-bend limiting [as] because of its large diameter thick sheath, it cannot be kinked beyond the point of ceasing to pass light. You probably have one in your home if you subscribe to fiber-to-the-home services (FTTH).

FTTx home installs are the genesis of our inspiration, where the desired use of ruggedized cables prevents use of field-termination with a splice on or mechanical connector, which are difficult to install on cable with a large diameter. This explains why pre-connectorized patch cords are used in FTTx.

We answered the challenge of finding a solution for pulling such 4.8 mm patch cords through walls and floors, while accommodating the smallest possible drilled holes to minimize damages to homes."

The company's first PulR model 4.8-mm-SC-Rugged is postioned for indoor FTTH installations, between the cable network interface device (NID) at the electrical baseboard, and the location of the passive optical network residential gateway.

The PulR for SC connectors tool is available in ruggedized (12.5 mm hole in the wall) and slim (<10 mm hole in the wall) versions. The ruggedized version comes in an installer’s kit with a few pulling sticks inside a transport case; the slim version is designed for OEM applications, made for inclusion in a bag of patch cords pre-mounted at the factory.

The company emphasizes that it has designed the PulR "to be very affordable." The tool is made out of recyclable plastic and injection moldable, ensuring both affordability and mass production.

"Just think of having to drill through the mortar thickness between two bricks," noted a PulR Technologies representative. "The drill bit is thus constrained in diameter such as to not damage the bricks. We solved the problem of pulling in small conduits by attaching a PulR to a pull cord. We developed a method of attaching PulR to an existing cable, to replace it with the optical fiber attached to the PulR. We also developed a procedure to pull across several overhead ceiling tiles without removing them."

Learn more about PulR Technologies.

For more news, projects, and profiles in the ICT cabling and connectivity industry, subscribe to CI&M’s newsletter and follow us on LinkedIn, Twitter, and Facebook.

About the Author

Matt Vincent

Senior Editor

Matt Vincent is a B2B technology journalist, editor and content producer with over 15 years of experience, specializing in the full range of media content production and management, as well as SEO and social media engagement best practices, for both Cabling Installation & Maintenance magazine and its website CablingInstall.com. He currently provides trade show, company, executive and field technology trend coverage for the ICT structured cabling, telecommunications networking, data center, IP physical security, and professional AV vertical market segments. Email: [email protected]