A popular choice for cable support, trays offer a variety of options.

Installers and users of structured cabling systems who must efficiently route clusters of cable from communications rooms to work areas are also tasked with providing proper support and protection of those cables. And a number of factors-including the physical environment of the installation, the number and type of cable being installed, and the number of branches that will shoot off from the main cable path-can influence which support mechanism the user chooses. (For a list of duct, raceway, and cable tray manufacturers and products, see page 50).

"Cable trays are support systems that can support cables and raceways," says Jim Sargent, senior product manager with Cooper B-Line, explaining the technical differences be tween cable-support systems. "Raceways are expressly made to contain cables; conduit is an example of a raceway system. And duct, as an electrical duct or cable duct, is referred to in the 1999 National Electrical Code as a conduit encased in earth or concrete."

Of the options available, cable tray is a popular choice. Trays are sturdily constructed to support a high volume of cables, making them good choices on high-cable-density projects. And although the trays are sturdy, manufacturers' developments have ensured that they are not rigid devices, inflexible to the circuitous path that cables frequently take through a structure.

The case for cable tray

"They are very time-tested, safe support systems for cabling systems," Sargent says. "With the development of high-tech cabling systems, more installers and designers are starting to use these fast-to-install, open-for-future-change systems." He says those considering specifying enclosed systems must deal with slower installation times, and limited cable capacity. And once enclosed systems are in place, he says, inspecting the cables inside is difficult, and identifying and removing abandoned cables even more so.

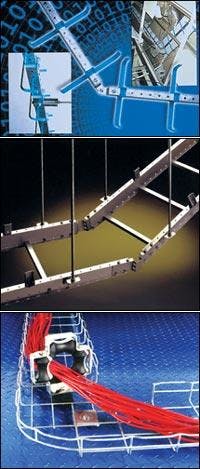

The NEMA VE-1 cable-tray standard recognizes (from top) single-rail, two-side-rail, and wire-mesh systems.

"There are three major classifications of cable tray: traditional two-side-rail, single-rail, and wire-mesh," Sargent further explains. "The NEMA (National Electrical Manufacturers Association) VE-1 standard is for metal systems, and it includes two-side-rail, single-rail, and wire-mesh systems. The NEMA FG-1 standard is for fiberglass systems."

Cablofil's Dawn Campbell says that modifications, particularly to tray accessories, frequently come from customer feedback. Among the Cablofil products that have been developed in response to customers is the FAS Roller, which attaches to Cablofil's wire-mesh tray and includes four rollers that act as a pulley for cable being pulled through the tray. The EZ T90 Kit is another such product. The kit contains the hardware for two 90° bends, and can be used to form a T-shaped bend in a cable tray.

Roger Jette, president of SnakeTray, concurs: "Customer feedback has prompted some of our products, including the original tray and Snake Canyon. Also, we have modified the sizes of our products in response to customer needs." One of the company's latest products is the Half-Section Snake Canyon, which is available in 2-, 4-, 6-, and 8-inch depths and, like the Snake Canyon, is intended for use under access floor systems.

Installation practices

An organization called the Cable Tray Institute (CTI-www.cabletrays.com), which counts Cooper B-Line among its members, has in conjunction with the NEMA published NEMA VE2-2001 Cable Tray Installation Guidelines. The standard can be downloaded from the CTI's Web site. It contains guidelines on everything from receiving and unloading cable-tray products, to storing the products and adding cables to a tray after its original installation.

The 46-page standard includes sections on installation of the tray, installation of cable, and maintenance. Tray-installation subsections cover installation tools, support installation, straight-section installation, fittings installation, field modifications, accessories, and grounding and bonding. The section on cable installation includes subsections on handling and storage, cable-tray preparation, cable-pulling considerations, pulling the cable, fastening of cables, and protecting installed cable.

The document assumes the installed tray will hold electrical cables, and states "a qualified person is one who is familiar with electrical construction. In addition, the person is trained and authorized to test, energize, clear, ground, tag, and lock out circuits in accordance with safety practices."

Cablofil's Campbell says a move toward international standards and codes may be around the corner. "Some favor a move toward an international electrical standard," she says. "Today, some users are asking which code to follow because there is more than one."

Application-specific considerations

Campbell also says that cable tray choice sometimes depends on specific physical characteristics within the environment in which the tray will reside. "The tray may go under a floor," she says. "Or, it may go into a corrosive environment, in which case the finish will be a factor.

"A recent trend involves industrial use. Many standard products are 2-by-12 inches for commercial use. But in industrial environments, 2-by-4 inches is common. That means developing smaller accessories to fit 2-by-4 systems. As the application changes, the accessories have to follow."

Patrick McLaughlin is chief editor of Cabling Installation & Maintenance.

null