Nevada Power throws switch to all-copper

Faced with the need to provide expanded bandwidth capabilities to an expanding workforce, Nevada Power Company transformed its RG-62 networks to a switched Ethernet LAN configuration by choosing an all-copper system rather than build upon its half-fiber/half-copper communications network.

The money-saving installation was comparatively easy, says Chuck Benton, network analyst for Nevada Power. "I didn't have to change my stock, and I didn't have to run on fiber and copper. Not having multiple fronts here was a very big plus for me." In the process, the company saved money because it did not have to invest in optical-fiber components that would have been needed to light the dark fiber. It would have cost Nevada Power an estimated $306,698 to light the dark fiber, but by using Belden's (www.belden.com) DataTwist 600e cable, the cost came to $249,854.

null

Change to switched Ethernet

Nevada Power, located in Las Vegas, is one of 15 power company buildings located throughout the state. Faced with a remodeling mandate, Nevada Power's story began when employees looked at its network and realized it needed greater workstation flexibility and future-proofing capabilities. The company sought a network infrastructure with a lifespan of 15 years, and it was during this decision-making process that the company made the unusual choice of building up its copper network instead of lighting dark optical fiber.

Nevada Power had been relying on Belden cabling and service for more than 22 years. In 1981, the utility had standardized on Belden RG-62 coaxial cable for its 3270 and token ring data networks, and was pleased with its quality and performance. The cabling was deployed in the main facility in Las Vegas, and later, 25 miles of the RG-62 coax cable was installed within a new building on campus.

In 1996, Nevada Power representatives decided to migrate from a mainframe data network to a switched Ethernet LAN. The project was scheduled and budgeted for installation over several years, since 12 properties would have to be totally revamped—power plants, warehouses, public offices, and the corporate headquarters in Las Vegas. Since the project was so complex, management wanted to ensure ample headroom for future communications advancements. As "future insurance" to the Category 5e DataTwist 350 cable, two multimode fiber runs were also installed on all four floors of the building so that in time, each workstation would receive two Category 5e connections and two fiber runs. The fiber to the desktop remained unlit.

The DataTwist 350 infrastructure proved fully capable of supporting the corporate data network, which included the company's Enterprise Resource Planning (ERP) system, a data-intensive enterprise business application. But the company began experiencing growing pains when it planned to add on an additional 35 people in 2002. This called for a remodeling of Nevada Power's fourth floor, and a reevaluation of the structured cabling system.

The building has about 4,500 desks, each with two runs of dark fiber running to them—a total of 900,000 feet of dark fiber. The four-story building has a totally optical fiber backbone, with three wiring closets per floor and a main central computer room. The horizontal network is a mesh of an all-fiber run on Gigabit Ethernet. From there, it runs copper cabling from 10 to 100 Mbits down to the floor.

A tight timeline

The new employees would work in an online customer calling center on the building's fourth floor. "We had to have things go smoothly, but the problem was I was on a tight time frame," says Benton. "We had never put fiber to the workstation, never driven it. So, there were unknowns by my staff."

The remodeling called for a reconfiguration of workstations, since Nevada Power uses modular work areas, and employees are often forced to relocate to take care of business or facility needs. Representatives agreed up front that the new system would need to support its requirements for a minimum of 15 years. Benton says the company performed a cost, needs and time analysis. It factored in the issue that such a customer service-oriented company could not afford any downtime.

Calculations showed that an all-copper DataTwist network (Cat 5e and enhanced Cat 6) would provide the company with a lower total cost of ownership than a fiber/copper network, while providing the same future-proofing insurance. It was a decision that Benton at first found troubling: "We never did use fiber-to-the-desk. I had laid it in in 1996. I designed a system and thought we'd get a lifetime out of it. Now, here I am putting in copper and abandoning fiber."

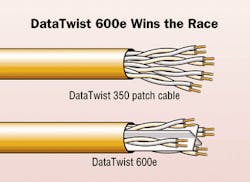

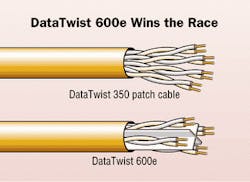

Nevada Power's all-copper solution coincided with the recent launch of DataTwist 600e, a Bonded-Pair UTP cable designed to perform beyond Category 6 standards. In switched Ethernet networks, such as Nevada Power Company's, DataTwist 600e cables are designed to deliver electrical performance characteristics far above Category 6 standards. The cable is designed to provide additional headroom for unforeseen factors such as substandard patch cords, flawed Network Interface Cards (NICs), and environmental noise factors such as electromagnetic interference (EMI).

NetVersant—Nevada, Inc. (www.netversant.com), a Houston, Texas-based national network solutions provider, was chosen to install the DataTwist 600e. Matt Engle, director of sales for NetVersant, says the installation team is not often asked to expand on a copper network when optical fiber is already available. "As far as Cat 6 being used to replace a fiber-to-the-desk network out there, this was a first for me," says Engle. But he also notes that at least 25% of the new cabling projects his company takes on involve Category 6—more than double the percentage of Category 6 installs that his company completed a year ago, before the standard was ratified.

Engle describes the DataTwist 600e cable as "heavy," and, "When you terminate it, it takes 50% more time than Cat 5e," he says. But conversely, Engle says the cable "flies" through all testing procedures, saving time during the final installation steps. "It's a much more robust cable with far less room for error," says Engle. "Once we get everything terminated, the testing is done once and we don't have the 10% of the test failures we have on other installations."

There were other advantages to the plan. Going with an all-DataTwist network would also mean that the network could remain up and running during the installation. That wouldn't have been the case if the company had decided to light the dark fiber, which would have required having to dismantle most of the network, including changing from NICs and switches that accept copper cable to those that accept fiber cable.

On the other hand, if the company had attempted to combine optical fiber and copper in its revised network infrastructure, it would have had to shut down the network as it reconfigured the existing termination cabinet. "We didn't want to put an unknown in the equation by going this way," says Benton. "Confidence was most important. We couldn't afford to have all those groups down."

Installation challenges

The installation began in March and ended in June. To get the job done, installers had to remove the roughly 700 fiber connections at the distribution hubs and install the DataTwist 600e to the relocated user workstations.

The true challenge came when installers tried to find a way to run the cable to the workstations. All existing cabling had been fed up from the floors to each workstation. Since none of the workstations could be shut down during the installation, installers decided to place a cable tray pathway throughout the ceiling. They would then run the cables down through power poles to each station.

As they placed the trays, installers had to work around water pipes, sprinklers, electrical equipment and other obstacles. "This was the biggest challenge," says Engle. "We had to figure out distance limitations, how long to run the cables." Installers then put a distribution box into the floor, drawing the Category 6e cable up and running it overhead into the ceiling.

To avoid disruption, the NetVersant team completed all installation at night and on weekends. In the initial switched Ethernet installation, more than 4,000 drops (800,000 feet) of DataTwist 350 had been installed. In this new phase, 574 drops (124,000 feet) of DataTwist 600e were connected.

The DataTwist 600e cables, traveling through the above-the-ceiling cable trays, now support the corporate LAN as well as video, voice, HVAC control and security applications. In addition, a T-1 link has been installed to bring Nevada Power's training center online in a 100 Mbit Ethernet system—without changing any of the cable.

To accommodate the utility's need for workstation mobility, installation technicians used the cable trays as well as flexible conduit to hold extra cable designated for network reconfiguration. Modular work areas are served by distribution boxes with 12 outlets, and each desktop in the network has its own bandwidth provided by two Cat 5e and two Cat 6e cables per cubicle.

null

Benton says the installation team installed cones in the ceiling that were spooled with flexible conduit to hold spare cable. This gave them the slack needed to move distribution boxes from their original locations to areas 25 to 50 feet away, with no performance degradation after termination, and no need to call in a NetVersant technician.

Savings and performance

Benton says the project came in on time and within budget, and is already delivering a return on investment. He says the accounting department alone is reporting a 40% decrease in the time it takes to transfer or download files.

He also says Nevada Power is leveraging its advanced videoconferencing system to great advantage. The online training center initiative has resulted in a dramatic reduction in outsourced training and travel costs. In addition, the system is used as many as six times a day, often simultaneously, for communications and meetings between individuals at various locations. He estimates that videoconferencing alone has saved the company $270,000 during the past 14 months, since it eliminates travel time between company sites.

Brian Milligan is senior associate editor for Cabling Installation & Maintenance.