Fiber-to-the-apartment: A new reality

From the August, 2015 Issue of Cabling Installation & Maintenance Magazine

Dakota Central Telecom and Clearfield teamed up to bring fiber-optic cabling not just to the building, but to each unit in a 163-resident complex in Jamestown, ND.

By Tom Warren, Clearfield

In construction, timing is everything, especially when it comes to wiring buildings for telecommunications services. When Dakota Central Telecommunications (DCT) approached IRET Properties about a new apartment complex that IRET was building in Jamestown, North Dakota, the timing was just right—and resulted in one of the first fiber-to-the-apartment deployments in the upper Midwestern United States. The project, developed with fiber management solutions from Clearfield, also makes the buildings future-ready, with the high-bandwidth requirements it's sure to face in the future.

The new apartment complex comprises 163 apartments, an office, and general common area. The three-story buildings are designed in a U-shape that interconnect by corner units on the ground floor. The complex has underground parking beneath the entire structure.

In on the ground floor

Very early in the construction process for the Jamestown project, DCT contacted IRET Properties, which owns and operates apartment communities throughout the Midwest, and struck an agreement under which DCT would provide triple-play services (television, telephone, Internet) to the apartments. The plan: Run fiber to every apartment, not just to the multi-dwelling unit (MDU) itself.

"Every customer DCT serves is fiber-to-the-home, so we're a big believer in taking fiber right to the customers," said Rodney Wolters, central office technician at DCT. "For this project, we wondered if we could transfer that same thinking to the apartment environment. This is a state-of-the-art installation, but would it be economical? How would the costs compare to taking a less-forward-thinking approach?"

The challenge to contain both the equipment and installation costs meant getting buy-in from the executives at IRET that they were creating a state-of-the-art, future-ready communications infrastructure that would deliver a strong return on investment. It also required buy-in from the compans information technology staff, which needed to validate the system itself.

Mapping out the plan

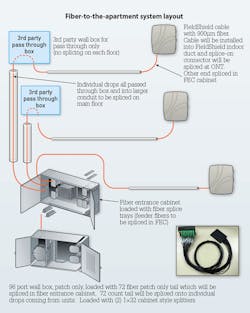

DCT worked with its reseller and solutions partner to design an elegant plan that took the building's layout and connectivity needs into consideration equally. Because DCT started the discussion early, it was able to work with its partners to draft the plan while the complex was in its early stages—before walls went up and ceilings were finished. To speed construction and occupancy approval, the plan provided for each of the three buildings to have its own demarcation location, creating what was, in essence, three smaller projects.

The most significant buy-in came when IRET's IT staff was brought on board to validate the technical nature of the project. The team not only signed off on the plan, but declared it the best communications solution in any apartment complex across IRET's multi-state holdings. Wolters said that once the IT staff blessed the plans, IRET's management was soon to follow.

The plan included designing and installing the system when the building's framing was up, but before any finish work was started, simplifying the installation process significantly and allowing for minimal disruption to the property when installing the microduct and fiber. DCT selected Clearfield's 10-mm FieldShield Riser Rated Microduct to provide a durable, flexible solution with a small footprint. The electrical contractor ran the FieldShield microduct from the demarc in each building to each apartment, with a larger conduit running from the floors to the basement. This design created repairable pathways from each unit to the basement, so that if in the future a fiber becomes damaged at either end, no walls need to be ripped apart to solve the issue. The design also allows DCT to increase capacity by running additional fibers as needs dictate, making the complex's communications capabilities future-ready.

"The electricians were really unsure about this process when they started, but as soon as they started to work with the Clearfield microduct, they said, ‘I wish we could do this on all the apartments from now on,'" Wolters recalled. "The microduct was easy to run and had the flexibility to bend where we needed it to, without kinking. It was very easy to pull one tube to each unit."

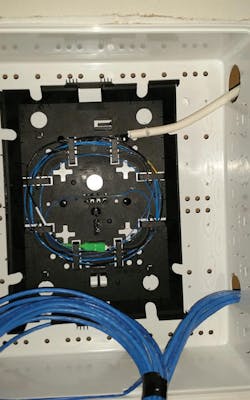

Next up was delivering Clearfield's 3-mm FieldShield microfiber to each apartment. Fiber was run through the microduct from each apartment unit back to a main collection point on each floor. A larger conduit was used to run the fiber from each collection point to a FieldSmart Wall Box with 1x32 splitters that was installed in the basement. Again this created a repairable, upgradeable pathway between each unit and the optical splitters. Clearfield's pushable fiber solution meant no splicing on each floor.

The Clearfield solutions for Jamestown exemplify the company's Labor Lite mantra; they simplify installations and remove much of the labor cost associated with typical installations. In a little more than an hour, two DCT technicians were able to pull fiber to 17 apartments.

"It was such a smooth, easy process," Wolters said, adding that DCT worked with the electrical contractors to reduce their expense and materials which, in turn, reduced the overall project expenses. "We had one pull, and that's it. Because we did not have to pull multiple runs of coax, Cat 5 and other communication cable to the apartments, the process was not labor-intensive at all, and that helped reduce costs significantly. When looking at the cost of a project, it's often not just the cost of the product that needs to be taken into consideration from an overall cost perspective. It's also, ‘How long is it going to take me to install this?' By using FieldShield pushable fiber, a lot of that cost was removed from the equation."

Seeing results

By placing Clearfield's 1x32 passive optical network (PON) splitters at the MDU, DCT is only using six fibers from its network to supply services to customers in the 163 units. "If we did not run fiber to the apartments and used Cat 5, we would have used 24 fibers from our network to serve the same number of customers," Wolters said. "The fact that we only had to use six fibers helped contain costs considerably."

The microduct solution allowed DCT to quickly and inexpensively deliver fiber connectivity to each unit. The solution reduced installation labor times and minimized disruption to the physical structure. The result was a small-form-factor repairable solution that provides an upgradeable pathway.

The big buzz is gigabit-speed service to the home. And with the Calix 844G optical network terminals in play, DCT is bringing a 4-Gbit/sec port directly to the apartment, allowing it to also offer 2.4-GHz and 5-GHz WiFi to connect all the tenants' devices.

The new demarc

The Jamestown area is growing, and Wolters said the example set in this installation is the roadmap DCT will follow for future MDUs, taking fiber all the way to the apartment. The simplified nature of the Clearfield products allowed DCT to remove from the equation much of the labor cost associated with installation, making fiber-to-the-apartment a feasible solution for future MDU projects.

A recent development at Clearfield is FieldShield Strong Fiber and the Deploy Reel. "This product was not available for this phase of the project, but we'll plan to use this in future build environments where we can take advantage of its small size and footprint," said Wolters. StrongFiber will further reduce labor times by providing up to 300 feet of preterminated fiber on a small reel. Using StrongFiber, a pullable SC connector can be pulled directly through the microduct to a wallbox and a push-on connector housing can be installed to complete the plug-and-play solution. No splicing will be needed.

"We've future-proofed the apartment complex," Wolters concluded. "Electronics come and go, but fiber is still king in terms of a bandwidth requirement. Why not take the opportunity to install fiber into a new or remodeled building, so that all that's needed is an equipment change, not a rewire job, to meet higher-bandwidth requirements that we'll inevitably see in the future?"

Singlemode fiber going right to the last foot of service--that's the new demarc.

Tom Warren, an applications engineer with Clearfield (www.clearfieldconnection.com), has been with the company for more than 10 years providing customer support with fiber-optic systems as well as on-site and classroom training.

Archived CIM Issues