Hardware for labeling your cables

Tom Davis

Oregon Department of Transportation

Problem

Identification labels are an essential part of the documentation of any network. Too often, though, the only visible signs of labeling in the telecommunications closet are the rack panels marked with felt-tipped pens or some handwritten notes on the plywood walls. The problem for cabling installers is how to permanently label crossconnects and cable bundles--quickly, inexpensively and on-site.

Solution

One solution to this problem is to use plastic tag holders such as those manufactured by Almetek Industries Inc. (Hackettstown, NJ). These holders are available in several widths and can be cut to length. They are attached by cable ties to cables, wires, panels and equipment.

The Almetek tag holders come with one-at-a-time letters and numbers, but it is easier and quicker to use a pressure labeler such as the Dymo device made by Esselte Pendaflex Corp. (Garden City, NY). Such labels can be quickly prepared in many different formats on-site. The labels can be mounted directly to crossconnect panels and equipment by using magnets or the labels` adhesive backing. If you leave the adhesive backing covered, the labels can be inserted into the channels of the tag holders.

When changes to the cabling plant occur, the old labels easily slide out of the channels to make way for new ones. A nylon button keeps the labels from falling out.

Label tapes come in different colors, enabling you to identify critical cables and circuits or separate voice and data cables through the use of color-coding.

If you must include more text than a simple alphanumeric location code, try die-cut card-stock inserts for AT&T 110-type punchdown blocks. The inserts fit without modification into 1/2-inch tag holders. A portable manual typewriter can be used to avoid handwriting. A single card insert will hold three lines of typescript and can be 10 inches wide--a good size for leaving warnings or special instructions attached to a cable.

In addition to being inexpensive, these labeling techniques can be used in a building that is under construction where no AC power is available. Both methods take advantage of low-cost, off-the-shelf components fitted together in an unusual way. Avoidance of a single local area network failure that results from a lack of a properly identified cable will pay for all materials used in a year. When failures do occur, labeled cables and ports make restoration of service easier and faster.

Procedure

1) After selecting the cable to be tagged, cut the tag holder to the proper length to hold the required text.

2) Use a pressure labeler to print the text on a correctly color-coded tape.

3) Leaving the adhesive backing on the tape, slide it into the tag`s channel and attach the tag to the cable with cable ties.

4) Dress the cable ties by clipping off their free ends and test the label to make sure it is secure in the tag holder.

5) For longer messages, use a portable manual typewriter to record the text on die-cut card stock inserts for AT&T-style 110 punchdown blocks. Use a 1/2-inch Almetek tag holder and attach to the cable as outlined above.

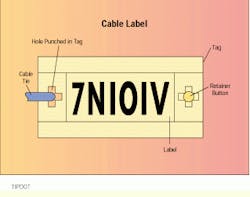

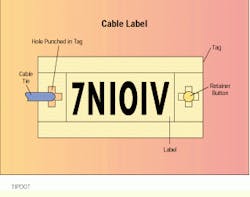

A cable label can be created from off-the-shelf components. Cut a plastic tag holder to length, leaving room at each end for holes to be punched. One hole takes a cable tie, and the other takes a plastic dot to hold the label in place. Use a pressure labeler to create the label; leave the adhesive backing in place so the plastic tag can be reused.

Tom Davis is a senior network facilities planner at the Information Systems Branch of the Oregon Department of Transportation, Salem, OR.