Method avoids link model problems and increases likelihood of passes.

Mark Johnston / Microtest

Why are there higher incidences of failures on tested Category 6 links than on Category 5 links? The fundamental reason is the effect of unspecified parameters adding near-end crosstalk (NEXT) or return loss that is not accounted for in the link testing model. A channel test, however, offers more margin if done with a standards-compliant Category 6 methodology. Channel testing completely cancels the channel connection but measures all of the patch cords' performance. Using this type of model when field testing Category 6 cabling will avoid link model problems and increase the likelihood of passes.

There are several compelling arguments for using the channel testing model. For one, a link testing model does not include effects of a close-in consolidation point (CP) connection. Today's link model limits are calculated with the assumption of one connection at each end of a 90-meter cable. But this model also allows a CP near the terminal outlet (TO) to accommodate the case of modular furniture or open office designs.

This "extra" connection can be as close as 2 meters from the TO. In this case, you have the NEXT and return loss effects of two connections where the limits were based on only one. This additional unaccounted-for connector can, in some cases, cause an otherwise compliant link to fail.

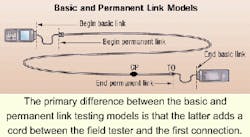

Additionally, consider that using a permanent link testing model rather than a basic link model reduces available link margin by up to 2 dB. Draft 5 of the proposed Category 6 standard used the traditional basic link definition, but in drafts 6 and 7, a change was made to the permanent link definition to comply with international standard harmonization efforts.

The essential difference between the two models is the addition of the cord between the field tester and the first connection. The permanent link includes the cord; the basic link does not. (See figure, above.) This cord material is normally constructed of stranded, individually pair-shielded cable to minimize crosstalk and measurement error. For Category 5 and 6 measurements, the test cord can be considered to have zero NEXT.

Consider the measurement at the TO end of the cable, assuming for simplification there is no CP. The first and largest source of NEXT will be the TO connection. Since the NEXT must travel through the 2-meter test cord, however, attenuation of the NEXT signal occurs before it is measured. This is normal and expected in the basic link model, where the NEXT you report is less than the NEXT at the TO by an amount equal to the two-way attenuation in the test cord.

In the permanent link model, however, the measurement interface changes so that the two field testers must "restore" the original magnitude of the signal at the TO. This can easily be done with today's advanced testers. The net effect is an elimination of the approximately 2 dB of beneficial NEXT attenuation of the test cord.

What does this all mean? Since the limits did not change, it means when you switch from Category 6 draft 5 to draft 6 or 7 (which means you switch to the permanent link model), you will have 2 dB less margin than you had with the basic link at high frequencies. Given there was very little margin to begin with, this worsens an already challenging situation.

Truth about NEXT

Telecommunications Industry Association (TIA-Arlington, VA) models assume that all NEXT is caused by differential NEXT coupling. This is not the case. Far-end crosstalk (FEXT) is reflected back to the measurement interface on two paths due to return loss effects. Depending upon the nature of the connectors, cables, and distances involved, this reflected FEXT can be a first order contributor of additional unspecified (but real) NEXT. This represents a crosstalk source not accounted for in the model.

As mentioned earlier, NEXT coupling is assumed in the TIA model to be due purely to differential coupling. If any link components are not properly balanced, there is a common-to-differential-mode crosstalk conversion that appears at the measurement port as additional unspecified (but real) NEXT. This represents another crosstalk source not accounted for in the model.

Another motivation for using channel testing on Category 6 links is the fact that lingering connector interoperability issues reduce link performance. It is relatively common knowledge that we do not have universal connector interoperability on Category 6 systems. While progress is being made, there are many so-called Category 6 plugs and jacks from different suppliers that, when connected together, yield only Category 5 performance.

When making a permanent link measurement, unless you have a supplier-matching plug on your test cord, you run the risk of sub-optimal connection performance. Do you want the expense, bulk, and inconvenience of having to have multiple link adapters?

The channel model of testing also offers more margin. Because of the above-mentioned effects, the permanent link has very little margin, and in some cases, negative margin. This is in spite of the fact that all link components could be fully Category 6-rated. The fault is in the incomplete link model, not the cable or connectors. Most of these problems, however, can be avoided or much reduced in scope if you choose to run a channel test. The channel configuration has more available margin than the permanent link, which is a compelling reason itself.

Performance is what counts

But why else might you wish to run the channel test rather than the permanent link test? One reason is Category 6 channel performance.

The latest draft of the Category 6 document is currently under ballot, and the committee under a great deal of pressure to publish it. The final document, when approved, is not expected to change substantially from the current draft. While there is little debate that the issues mentioned here are real, there is much debate about the magnitude of the contribution they make. In addition, link limits have been harmonized with international standards, so there is little hope of getting them adjusted. We will likely have to live with the limits as they are now.

So, if you are a Category 6 end user or active equipment manufacturer, you are most interested in the channel performance anyway. You cannot be sure your application will run until you test the channel. Patch cords vary widely in performance, and it is quite possible to have a passing permanent link and a failing channel. With a channel test, the customer gets the best assurance of a good system.

Furthermore, most Category 6 system warranties are based on channel performance. If you examine warranty details, they are in almost all cases channel-based, which is appropriate because of end user needs. If you are warranting channel performance, doesn't it make sense to certify channel performance, too?

International standards bodies also recognize these problems and have recommended channel limits be used for testing. In the latest draft of IS11801 2nd Edition, there is a recognition that the permanent link model may not adequately represent the performance of an installed Category 6 link. In Annex E Section E.3.2, it says in part, For the case of a third connector (CP) in the permanent link, there is the possibility that the permanent link requirements are not totally met. In that case, the channel NEXT loss limits may be used to verify the performance.

Channel testing on Category 6 cabling is only possible if you have a standards-compliant adapter. That means the adapter must fully cancel the mated connection in the adapter, while preserving measurement of the entire patch cord. One method to support this is via adaptive vector cancellation (AVC) technology, which adaptively subtracts the NEXT and return loss in any mated channel connection.

In summary, if you install or maintain Category 6 structured cabling, channel testing offers many advantages:

- Much higher probability of passing;

- A more useful certification report for the end user;

- An exact match to system warranty claims;

- Lower cost (do not need additional link adapters);

- More repeatable over the long term (no concerns about link adapter wear and tear); and

- Compliance with TIA and international structured cabling standards.

Mark Johnston, RCDD, is senior director of technology development at Microtest (Phoenix, AZ). A voting member of the TIA, Mark also participates in ISO and CENELEC cabling standards work. A nine-year BICSI member, he is active in the organization's Technical Information and Methods committee. Mark is also on the technical advisory board of the Certified Network Experts Consortium, where he created the LAN Cabling Exam. You can contact him via e-mail at: [email protected].