Prevent condensation and airflow problems in conduit

Roy Thomas

OnLine Systems

Problem

Vacant or partially filled conduit is prone to condensation if it passes from one temperature zone to another, such as from indoors to outdoors or from one part of a building to another. This condensation can be harmful because it can damage the cable or cause mildew. Even more important, if the lower end of the conduit is unsealed, water can actually drip into equipment under some circumstances.

We used to seal the top and bottom of such a conduit to prevent airflow but realized that if we could not seal both ends for any reason, a lot of sweating would occur. Our solution is to stuff standard fiberglass building insulation into the colder end of the conduit to prevent a sudden temperature change. But the problem is that in some cases you may have to push the insulation quite a distance into the conduit to reach the point of temperature change.

Solution

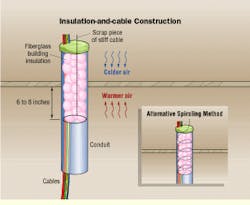

We have implemented the building-insulation idea. But first, we take a piece of 12-gauge, 2-conductor flexible, nonmetallic cable and curl it into a spiral at one end (any stiff communications cable will also work). Then we push the cable into the end of the conduit until the spiraled portion reaches the point we want the insulation to reach. We then push in the insulation. Finally, we apply duct seal to the end of the conduit. When you need access to the conduit, just pull on the flexible, nonmetallic cable and the insulation comes with it. All sweating/condensation and airflow problems are solved.

Procedure

1) Twist a single spiral, the diameter of the conduit that you are sealing, into one end of a scrap 12-gauge, 2-conductor flexible, nonmetallic cable, or any stiff communications cable.

2) At the end of the conduit that is in the colder environment, push the spiraled end of the cable into the raceway. Make sure the spiraled end crosses from the colder environment 6 to 8 inches into the warmer environment.

3) As you push the spiraled cable, follow it with fiberglass building insulation. Stop feeding the insulation when it is just short of the end of the conduit.

4) Seal the end of the conduit with duct seal.

5) If you ever need access to the conduit, to inspect it or add more cables, simply pull the spiral-ended wire out to get rid of the insulation.

When you are working with a large conduit that already has cables in it, you can spiral the scrap cable around the existing cables within the conduit, rather than forming a single spiral. Either way will work well.

A properly treated conduit will have fiberglass building insulation stuffed inside it, along with a scrap piece of cable, and will be sealed with duct seal. You can either put a single spiral in the scrap cable, or it can be wrapped several times around the existing cable in the conduit.

Roy Thomas is with OnLine Systems (Sanford, NC), which provides telecommunications development and designs Web pages.