Live testing prevents critical failures

E-commerce vendors especially require 24-hour, seven-day-a-week network uptime.

Andrew C. Jimenez / Anixter Inc.

Leslie Swanson / Vigilant Networks Inc.

Network outages and slowdowns seriously impact productivity, costing service providers and enterprises millions of dollars annually. The effect is apparent with network outages, but the cost of a network slowdown, or sluggish data transmission, is more difficult to measure. Until recently, detecting the cause of disruptions and slow traffic has been a time-consuming and costly trial-and-error process.

Limitations within computers and software can be the source of slow transmissions, but more often the problem lies within the network cabling system. A number of factors could be contributing to poor performance. For example, the cabling might be substandard. Even cabling that meets Category 5E standards might not perform efficiently in high-speed systems because of the standard's broad tolerance range. Furthermore, cabling and channel components do not always perform efficiently if they are manufactured according to different specifications and do not match when joined together to form the network's physical layer.

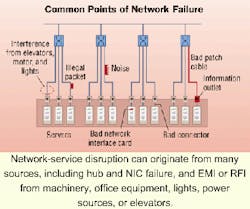

The blame might fall on the cable installation if that installation did not strictly adhere to industry guidelines. Changes or expansions made to the network can cause disruptions. Active devices such as hubs and network interface cards (NICs) sometimes weaken or fail, and environmental factors such as electromagnetic interference (EMI) or radio-frequency interference (RFI) from machinery, office equipment, lights, power sources, and even elevators can impact system performance.

Many of these problems go undetected until a network tries to transmit at new, higher speeds. Instead of accelerating transmissions, the higher speeds exacerbate the problems when the equipment cannot handle the upgrades.

Traditional network monitoring and testing devices evaluate cable and network performance but are unable to diagnose trouble areas. Remote monitoring probes, protocol analyzers, and handheld cable testers can detect the existence of a problem but are unable to pinpoint its location. More importantly, most of these tools are unable to test components while a system is operating. The network must be shut down so each port can be tested individually.

When field technicians and installers use handheld testers to test one line at a time, the process is slow and cumbersome. It requires two people-one to send signals through the line and another to receive them at the other end. Furthermore, handheld devices cannot test patch cords, which should be the easiest component to check and replace.

Revenue stream

All companies depend on their network systems to function properly and efficiently. The revenue stream for an e-business comes to a devastating halt when the network crashes or must be shut down for maintenance. In such situations, the stock price of the e-business typically is negatively impacted.

To ensure optimal network operation at peak performance, all the components in the network channel must be high-quality before installation, properly matched, carefully installed, and most importantly, continuously monitored-24 hours a day, seven days a week. Products must meet industry specifications, but some distributors go a step further to ensure quality. Anixter, for example, runs cabling products through its testing lab to make certain those products meet the company's own requirements for compliance and integrity before they are sold.

Once installed, however, cabling and other channel components might not perform properly. Passive examinations indicate the frequency or size of the information pipeline, but tests in active networks with live data verify speed. Anixter is currently testing procedures that evaluate products in live networks in its Levels Lab.

Testing active systems

Live testing before actual installation has enormous value, but the mission-critical e-business data centers hosted by the service providers and some enterprises must be continuously monitored. Network slowdowns and crashes can be devastating in these environments. The dynamics of the active network system change continuously; the performance of receivers and transmitters changes with time. Changes in temperature, light, and other environmental conditions can immediately affect the network throughput. Consequently, the live testing prior to installation is not sufficient for mission-critical e-business data centers. The cable demands continuous monitoring and live testing so that network managers can detect and preempt any potential problems that could negatively affect network performance.

Vigilant Networks Inc. (Burlington, MA), a subsidiary of LeCroy Corp., offers an embedded monitoring solution that can be permanently deployed into e-business data centers, providing continuous network monitoring and testing. The solution employs an architecture that the company calls Network System Characterization (NSC)-an architecture that views the entire network channel, testing and monitoring it as a system rather than as a collection of individual components. NSC uses a nonintrusive, high-impedance line tap to sample the signal information in the channel. It starts at the network's foundation-its physical layer-testing and monitoring its aspects, and works its way up to the network's application layer.

In addition to detecting the information that conventional monitoring tools can also see, NSC measures voltage, impedance, and timing, thus allowing network managers to view illegal packets, crosstalk, noise, and other events undetectable or overlooked by conventional testing devices. NSC identifies problems anywhere within the network, from NICs through the cable and connectors as well as routers, switches, and hubs.

Network managers can deploy NSC technology in the network's most vital region, typically beginning at the router, continuing through the switch/load balancer, and ending within the server farm-including all NICs within the servers. The NSC continuously tests and monitors this region of the network.

This relatively new technology provides an overall view of the active network, creating a map with the physical location of every device in that network region. A visual interface displays any component with real or potential problems. System managers can know exact locations of trouble areas, eliminating the time-consuming process of checking individual lines in search of their weak spots. The architecture allows the user to test 384 ports simultaneously, and it automatically adjusts its configuration documentation to reflect network changes and additions.

This monitoring method resolves several issues that traditionally have challenged network managers. The NSC technology is permanently deployed in the network, providing never-before-seen information that can help protect the business and, in doing so, maintaining customer and supplier confidence. Early-warning capabilities, combined with a map of faulty elements, allow quick problem resolution. Additionally, procedures that eliminate the need for trial-and-error testing save hours of labor and frustration.

The benefits of testing channel components in live networks before installation and continuously testing the live network are evident. It is only a matter of time before the newest processes are perfected and become common practice in all businesses.

Andrew C. Jimenez is director of testing for Anixter Inc. (Skokie, IL). Leslie Swanson is president and CEO of Vigilant Networks Inc. (Burlington, MA).