Michelle Abrams

What is the quickest way from point A to point B? This has been an age-old question, with the typical answer being: a straight line. It can be argued that the cabling industry's version of this question is, "What is the easiest way to connect point A to point B?" As the market is flooded with various connection methods, IDC blocks (see table on page 76) are an economical and easy-to-use method of connecting point A with point B.

An IDC block, often called a connecting block, is defined by BICSI (Tampa, FL) as an insulation displacement connector. While this tool has many names, such as punchdown block, it has one very clear function. Panduit Corp.'s (Tinley Park, IL) product manager, George Ayre, identifies it as simply connecting copper wires: "It is the most efficient and cost-effective method of connecting insulated copper wire in the world."

Like many integral components of today's cabling systems, IDC blocks were born out of the technological genius of AT&T Corp. (Bedminster, NJ). Ayre notes that before the invention of the IDC block, there were a variety of connection systems, such as screw terminals. These evolved into wire-wrap systems and finally to the IDC block.

IDC blocks are considered an advancement over earlier technologies because they allow for a gas-tight connection without the removal of the cable's insulation, plus they require fewer steps to secure the connection. Connection is achieved once wires are placed into the IDC block's contacts, and then punched down via a punchdown tool, pressing the wires against the contacts to form the gas-tight connection.

The 66 block

The first block introduced to the market became known as the 66 block. According to Benoit Chevarie, NORDX/CDT's (Pointe-Claire, Quebec, Canada) product manager of IBDN connectivity, its primary purpose was to service the central-office-type connection. The 66 block is de-signed with con-tact accessibility from the front, allowing wires to enter from either side. Additionally, these blocks have fanning strips, which Panduit's Ayre sees as extremely poor for labeling due to the small surface area provided for recording important identification information.

The 66 block, originally designed and still widely used for voice applications, contains contacts that are easily accessible from the block's front.

James Ellis, global product manager for Molex Premise Networks (Hudson, NH), says, "The 66 block is primarily used for voice communications because of the clip size." But while it may have begun as a tool for the voice segment of the market, it evolved to become a tool for the data side, too. In fact, James Wynn, a civilian technician for the U.S. Marine Corps, says that he has even seen 66 blocks used for Category 5 data transmission.

It is possible, according to Ayre. "It is a misnomer that 66 is only for voice," he says. "They can handle up to Category 5E but are not as efficient or cost-effective as 110 blocks."

Migrating to the 110

Often used for large installations, the 110 block evolved out of the 66 block, again from the lab oratories of AT&T. The 110 block is a smaller unit featuring a two-piece construction of a wire block and a connecting block. Wires are fed into the block from the front, as opposed to the side entry on the 66 block.

Chevarie notes that the 110 block is "a back-to-back connection whereas the 66 block is a side-by-side connection." This helps to reduce the space requirements of the 110 block and reduce overall cost. The 110 block's construction also provides a quiet front, meaning there is insulation both above and around the contacts. Since the quiet front is lacking on the 66 blocks, a cover is often recommended.

Ayre points out that, compared with 66 blocks, "110 blocks have a far superior labeling system that not only snaps into place but is erasable." This is particularly important for post-installation testing and maintenance procedures.

Krone and BIX

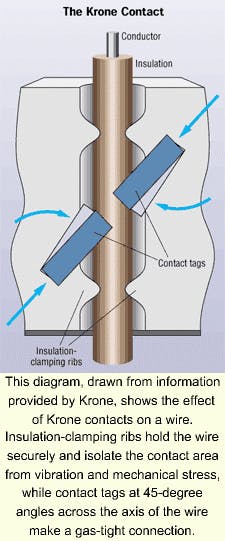

But the world of IDC blocks reaches beyond the basic 66 and 110 styles. A unique block style developed in Berlin, Germany by Krone Inc. (Englewood, CO) and later brought to the United States continues to bear the Krone name. The Krone block features silver-plated contacts positioned at a 45-degree angle to the axis of the wire. This is a drastic contrast to the contacts of the 110 blocks that are traditionally tin-plated and positioned at a 90-degree angle.

The BIX block features back-to-back connections in a one-piece modular design.

An additional differentiation is the parallel contact design, moving from the wedged approach of the 110 block. Senior systems engineer Mike Miller says the Krone design "results in wire retention force that is greater than the breaking force of the wire." This produces, in Miller's opinion, a secure and reliable connection.

As opposed to AT&T, which developed IDC blocks and then licensed them for use by any manufacturer in the industry, Krone has retained sole use of its patented design. Krone's Series 2 product line, featuring a 10-pair, Category 5-compliant design, was the first to be introduced to U.S. markets. Krone has since developed three additional products, designed to fit market niches currently targeted by the other block types.

Another niche block is the BIX, which was developed by NORDX/ CDT more than 20 years ago. Much like the design of the 110, the BIX features back-to-back connections. But it has a one-piece connector with a modular approach, as opposed to the 110's two-piece construction.

Chevarie says the BIX construction is easier to maintain and provides greater space efficiency, plus offers high performance (including Category 6) resulting from the block's unique construction. "It has a higher density," he says, "because the space between the contacts is close together."

Standards-driven

As with most cabling components, industry standards play an enormous role in IDC product development and selection. At the recent Cabling Installation Expo and BICSI Cabling Workshop, held in Atlanta, Vic Phillips, BICSI master instructor, clarified that a code, such as the National Electrical Code (NEC) is equivalent to a law and is criminally enforceable as compared to a standard, which is a guideline.

Phillips explained that everything electrically connected, including IDC blocks, must comply with Chapter 8, Section 110-3(b) of the NEC, which states that "listed or labeled equipment shall be installed and used in accordance with any instructions included in the listing or labeling." In simplified terms, IDC blocks must be tested by a third party ("listed" or "labeled"), and an installer must comply with the instructions provided by that party.

The NEC is the only such regulation on IDC blocks. Tradition-ally, the industry looks to ANSI/ EIA/TIA standards for guidelines on products. IDC blocks are not specifically covered under these standards, but their performance falls under standards for specific categories, such as 568A.

This diagram, drawn from information provided by Krone, shows the effect of Krone contacts on a wire. Insulation-clamping ribs hold the wire securely and isolate the contact area from vibration and mechanical stress, while contact tags at 45-degree angles across the axis of the wire make a gas-tight connection.

Since cabling standards, such as the proposed Category 6, call for higher levels of performance, block manufacturers are responding. Chevarie observes that "as new standards call for higher performance, IDC block manufacturers have decided to evolve their systems to meet these standards."

Category 6 impact

The Siemon Company (Watertown, CT) and Panduit Corp. have already developed and introduced 110-style blocks meeting the proposed Category 6 standards. Ayre describes Panduit's new Category 6 product, Giga-Punch, as "our fastest connector that outperforms all of Panduit's other connectors."

To optimize space, the Giga-Punch system features a contact design that spaces the contacts closer together. The block is an 18-pair design, resulting in space savings of 44% over traditional 110 blocks.

Krone also offers a block designed to meet the proposed Category 6 standard. The Ultima 8 block is an 8-pair block designed with a mounting system that lets numerous Ultima 8 blocks be added to the same mounting system. This system was meant to "grow incrementally," says Miller.

In a union of the old and the new, Molex has introduced the KATT product line, designed with a V-groove contact that lets two wires instead of one be placed into each slot. Both the 110-punchdown tool and the Krone tool can be used to terminate the connection. It can be concluded that the name "KATT" was derived from the dual use of the Krone and AT&T (110) styles of punchdown tools.

Choice factors

When selecting the proper block for specific applications, numerous factors need to be considered. For instance, if a quiet front is desired, then the 110 block might be the best choice. Likewise, if side entry is preferred, then a 66 block could be ideal.

Industry consensus seems to be that there are few, if any, "bells and whistles" when it comes to IDC blocks. It is important, then, to focus on your specific needs and select the style of block that best meets your criteria.

Some technicians find the 100 block easier to use than the 66 block because of easy accesibility.

Because of vast differences, Panduit's Ayre considers pair count as an important factor when shopping. Krone blocks, for instance, are an 8-pair design and most 110 blocks are a 12-pair design. Molex's Ellis says that in addition to ease of use and cost efficiency, installers should look for blocks that are easy to label. "Ease of labeling is important," he says, "so at the end of the day, once the wiring system is installed, you can expedite the testing process."

But BICSI master instructor Ed Phillips, president of Tel-comm (Winthrop, ME), believes that "cost should not be a factor but rather the ease of building systems and ease of termination." According to Phillips, if all installers looked for these qualities, the BIX would be the block most often selected.

A vast menu of options are available when it comes to selecting an IDC block, yet there remains to be a consensus as to the "best" type of block for specific situations. The traditional adage of 66 for voice and 110 for data has been discredited, and the BIX and Krone blocks have carved out their own niches in the market.

As strongly as Phillips believes the BIX block is the "easiest" to use, he feels "the 66 block should be outlawed because they are not as well made as they used to be." He adds that both the 66 block and the Krone block are "space hogs" because they take up a great deal more room than the 110 and BIX blocks, due to the placement of the contacts.

But Joe Jenkins, manager of operations for Select Tel Systems (Albany, GA), still relies on the 66 block for all his telecommunications uses. "The 66 block is a lot faster than the 110 for telecom," he says. He insists that manufacturers sell more 66 blocks than 110, if for no other reason than the 66 block has been around longer.

Wynn, of the Marine Corps, agrees with Jenkins. "Probably because I have been using them for so long, I prefer the 66 blocks because they install faster and easier." Yet, he does not mind working with the 110 blocks, although he has never had an opportunity to work with the BIX or Krone blocks for comparison. "I know what they are and I learned how to install them in my BICSI training, but we just do not see them."

Molex's Ellis notes that no matter which style of block you choose, the differences come down to how you apply the block. The easiest connection between point A and point B will depend more on your preferences, than on the specific IDC block.