Tension reduction, lubrication on high-performance data cable

Tests show some lubricant types have little effect while others induce performance variance and jacket-strength degradation.

The effect of lubricant on high-performance, low-voltage copper data cable has been a point of much discussion lately, because on occasion, data cable is failing attenuation testing in field installations where cable is pulled into conduit with the assistance of lubricants.

Because the use of cable lubricant is critical to minimize tension in these installations, a study has been fast-tracked to test the effects of lubricant on the cable’s signal properties. The study also includes measurement of friction reduction and the effect of lubricant on the cable jacket’s material properties.

Cable-lubrication history

Modern cable-pulling lubricants primarily are used for outside-plant (OSP) telephone and electrical-cable installations, and meet rigorous performance criteria specific to these uses. A good OSP or electrical cable lubricant will wet out on the cable jacket, providing a lubricating coating that will cling to the cable as it travels long distances through the conduit.

Almost all cable-pulling lubricants are water-based. Electrical lubricants are UL-listed and tested for compatibility according to standards established by the Institute of Electrical and Electronics Engineers (IEEE). Bellcore specifications address OSP pulling lubricants.

Standards established by the Telecommunications Industry Association (TIA) addressing cable installation limit cable fill, run length, and degree of bend in the raceway. Even with these limitations, in some cases, cable lubricant is needed; to maintain integrity, the cable must be pulled with less than 25 pounds’ force.

Contractors turn to the most convenient and readily available lubricant, which is almost always intended for OSP or electrical cable pulling. As the following test results will show, the use of such lubricants for high-baud-rate data cable installations is not always appropriate.

A new class of lubricant

Consider the special installation requirements for data cable before choosing or specifying a cable lubricant. An appropriate lubricant will reduce friction and cable-pulling tensions, should be compatible with the cable jacket material, and should have a limited effect on the cable’s signal and attenuation measurements.

A thinner, fast-drying lubricant that requires only a very thin coat has tested as the best choice for this type of installation. This new lubricant type is concentrated to reduce the amount of lubricant needed, and can reduce friction even when applied in very thin coats.

Diagnostic testing and the “wet link phenomena”

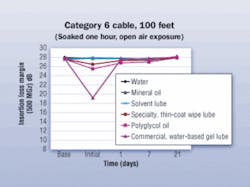

In the first phase of compatibility testing, Category 6 datacable is soaked in the lubricant at 23º C for one hour, and a full set of diagnostic tests are performed using a Fluke Networks DTX1800 and focusing on attenuation and insertion loss. All conditions and connection hardware are kept constant unless otherwise noted.

A control or baseline reading is taken before lubricant is applied. As an initial reading, a diagnostic scan is run immediately after the cable is removed from the lubricant soak. The cable is strung and allowed to air-dry, with test measurements at regular time intervals until the diagnostic readings stabilize.

The effect of the lubricant is immediate, and develops before the lubricant has any chance to permeate the jacket. As the lubricants are allowed to dry, the attenuation returns to the control level in one day to three weeks. In other words, testing shows the insertion loss effect is reversible.

The commercial water-based gel lubricant causes the greatest insertion loss, and the non-polar oils causes the least. The thin-coat lubricant shows a minimal effect, presumably because there is very little lubricant to absorb energy.

In the second phase of this testing, 300-foot sections of four unshielded Category 6 cables are wiped with the wipe lubricant, and a full set of diagnostic tests are performed on the cable. Immediately after application of the lubricant, each cable shows minimal insertion loss and “passes” the full set of tests.

Conduit test

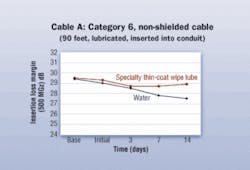

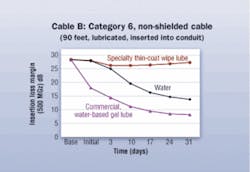

In the next test, 90 feet of unshielded Category 6 cable is coated with lubricant and pulled into a conduit. The conduit ends are then closed with duct-plug putty, so the lubricant is not allowed to dry. Plain water is used as one of the comparisons, and several cables from different manufacturers are used in this testing.

Interestingly, one brand of cable exhibits minimal attenuation loss and remains relatively stable over time, while another brand of cable exhibits continued degradation of attenuation performance over time. Performance is based on the cable. In general, the specialty wipe lubricant shows the least attenuation effect on these high-performance data cables.

Other lubricants

Almost all cable lubricants are water-based, but the preceding data shows that water content, especially in gel form, interferes with the data signals unless allowed to dry.

It might seem logical to use a mineral oil or solvent-based lubricant; but oils and greases were not developed for lubricating cable. The cable jacketremains in contact with the lubricant residue for the entire cable life, so the lubricant and jacket material must be compatible.

To test compatibility, six different jacket materials are stripped from cables or obtained in plaque form, and soaked for seven days at 50º C in the same lubricants tested in the first phase. The weight change, as well as tensile and elongation properties, are then measured for comparison.

When exposed to a solvent-based lubricant and to mineral oil, the jacket material shrinks and its elongation property is drastically reduced. The cable jacket becomes brittle and easily cracks and breaks. Testing shows that oils, greases, and solvents are not compatible with these jackets.

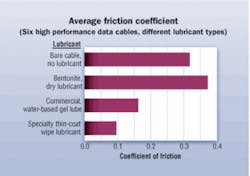

The primary purpose of a cable lubricant is to reduce friction. While “dry” lubricants will not have an effect on the cable’s signal properties or the jacket’s physical strength, these materials show little or no friction reduction on data cables.

Coefficient of friction is measured for the lubricants in this test on six different high-performance data cables. In this test, a single data cable is pulled into an EMT conduit with two 90º bends. For each pull, an initial back tension of 8 pounds is put on the cable. The pulling tension is measured and friction coefficient is calculated.

In the test, the pulling tension without lubricant and with dry lubricants is above 25 pounds’ force. Even in a short conduit section with two bends, this tension is above the maximum recommended. A thin layer from the wipe lubricant lowers the friction coefficient by 60% or more, resulting in dramatic tension reduction during the installation.

Thin is in

Cable lubricants must meet both performance and compatibility standards for the cable. New thin-film lubricants, using very small quantities, work well on high-performance data cables, reducing friction. Additionally, this type of lubricant shows minimal impact on the cables’ data-carrying capacity and does not degrade the physical strength of the cable jacket material.(The author and American Polywater extend thanks to Fluke Networks [www.flukenetworks.com] for supplying information and equipment in support of the testing detailed in this article.)

SHERI DAHLKE is laboratory manager with American Polywater (www.polywater.com).