Assessing the costs and benefits of SCTP cable

Choosing between UTP and SCTP requires a cost-and-performance comparison.

Jeffrey A. Lupinacci,

Brinjac, Kambic and Associates Inc.

For the distribution of high-speed signals in local area networks (lans) or compressed video applications, the network designer must choose a medium that will effectively transmit signals for current technologies as well as those anticipated for the future. Two types of horizontal distribution media that can be used in lans are unshielded twisted-pair (UTP) and screened twisted-pair (SCTP) cable.

SCTP cable is commonly used in Europe and has received more attention in North America lately due to the efforts of the Telecommunications Industry Association and Electronic Industries Alliance (tia/eia--Arlington, VA) and the International Organization for Standardization and International Electro-technical Commission (iso/iec--Geneva) to harmonize their respective tia/eia-568a and the iso/iec-11801 telecommunications cabling standards. Current specifications for SCTP are based on cable-construction specifications for UTP cable. The next release of the North American standard (tia/eia-568b) will include specifications for SCTP as an option.

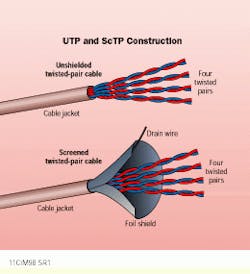

Both UTP and SCTP are copper cables constructed of four twisted-pair, 100-ohm, 24-American Wire Gauge (awg) solid conductors within a plenum-rated thermoplastic jacket. Each cable has a similar nominal physical size or outer diameter measured at approximately 0.22 inch.

Signal loss during propagation through the cable is called attenuation and is measured in decibels. Both UTP and SCTP have similar characteristics for attenuation, since attenuation is a factor of the size and properties of the copper cable itself.

Each cable is terminated on an 8-position, 8-pin modular plug specifically designed for that medium, and can be pinned out in either a T568A or T568B configuration following the telecommunications industry-standard color code, as specified by the Insulated Cable Engineers Association (South Yarmouth, MA).

The maximum allowable length for horizontal or backbone links for either UTP or SCTP is 90 meters. Most applications using these media are in a horizontal crossconnect, at the telecommunications closet (TC) in the form of a patch panel to the work-area outlet.

UTP and SCTP are handled in the same manner during shipment, storage, and installation. They also have many of the same installation guidelines for placement separation, maximum pair untwist, recommended maximum cable-jacket removal, allowable cable kink or twist, and distribution methods.

UTP cabling

UTP is made of four twisted pairs of solid copper wire housed in an overall thermoplastic jacket. Electrical balance between the two conductors in a pair and a uniform twist provide protection against electromagnetic interference (emi) and radio-frequency interference (RFI).

The minimum cable bend allowed is to a radius of 1 inch, or four times the cable diameter. If this bend radius is exceeded, the conductors are damaged. The cable is link-tested in accordance with telecommunications systems bulletin tsb-67 for field testing of installed UTP cable links.

A horizontal channel of 100-ohm UTP cable can be up to 100 meters long, comprising a 90-meter link and 10 meters of cordage. The tia/eia is issuing additional recommendations for Category 5 cabling that will support Gigabit Ethernet. These recommendations will impose more-stringent performance requirements on Category 5 in such installations. The result will be classified as Enhanced Category 5, or Category 5E.

Brinjac, Kambic and Associates recommends that clients install UTP cable that meets at least Category 5E specifications. This cable is manufactured to within stricter tolerances and is expected to be of finer quality than standard Category 5 UTP cable. But, for the sake of comparison in this article, standard Category 5, as specified in tia/eia-568a, will be used because the specifications for Category 5E have not yet been published.

When the level of performance for Category 5E is established, it will be imposed on both UTP and SCTP. Although Category 5E UTP will be more expensive than Category 5 UTP, it will still be less expensive per foot than Category 5E SCTP cable.

SCTP cabling

SCTP is a popular cable choice in Europe, where standards compliance for electromagnetic emission from the cable into the atmosphere is strictly monitored. Currently, an effort to more closely link the international and North American standards has brought 100-ohm SCTP to the U.S. market and standards-lobbying floors.

While UTP provides a 100-meter channel, SCTP provides only a 98-meter horizontal channel, comprising a 90-meter link and 8 meters of cordage. This restriction is based on the size of the screen, which does not allow the cable to fit into a standard modular plug. As a result, a 26-awg screened stranded cable, rather than a 24-awg cable, is used for patch cords.

An advantage of SCTP is its superior immunity to RF fields, which results in fewer bit errors. Because of its physical construction, SCTP has reduced near-end crosstalk. This construction typically consists of four twisted pairs of solid copper with a foil laminate shield and at least one tinned copper drain wire within a thermoplastic jacket. Impedance to emi and RFI is provided by electrical balance between the two conductors in each pair and a uniform twist. A correctly installed shield exceeds the emi and RFI impedance of UTP.

However, care must be taken to ensure that the drain wire and screen maintain continuity throughout the channel and maintain a single point of ground. A break in the ground screen, an incorrectly terminated ground screen, or a second contact with ground can cause a ground loop or noise. Such an incorrectly installed SCTP system would create more disruption to network signals than an incorrectly installed UTP system, and it would cost more to repair.

The minimum cable bend allowed for SCTP is to a radius of 2 inches, or eight times the cable diameter. The minimum bend radius of SCTP is larger than that of UTP because the screened cable is stiffer. The screen will be broken and the conductors damaged if the bend radius is exceeded.

SCTP link testing has not yet been established by the tia or eia. Although a draft standard covers the performance of SCTP cable components, it does not cover link performance for SCTP cabling systems. Since no minimum requirements must be met, an incorrectly installed link can remain damaged indefinitely.

The four pairs of both UTP and SCTP cables are terminated in the same manner, but the addition of the screen and drain wire in the latter creates further steps in the termination process. The screen and drain wire must be permanently terminated at the work-area outlet and at the patch panel in the TC. At the TC, patch panels must be terminated and permanently and effectively bonded to ground. There can be no open, or break, in the screen.

The effectiveness of the screen is quantified by its transfer impedance, but there is currently no standardized method of testing this parameter. Current lab practices are being agreed upon, but no field test has been developed.

Installation considerations

Many factors affect installation time and, thus, the cost of installing a horizontal link. These include the hours the building can be accessed; the level of security required for a crew; parking for trucks; pathway access; the quantity of work being performed during a service call; and the number of cable pulls per faceplate.

Many contractors bid a flat rate per drop based on an average. During the initial installation phase, when floor tiles have been removed and there are no occupants to work around, contractors are usually more efficient and beat the average. After the main installation or during moves, adds, and changes (macs), installation costs for a new drop increase greatly. This increase is based on the loss of economies of scale and the extra effort needed to minimize disruption to occupants. Additionally, during macs, the per-drop average changes if the contractor finds that the cabling medium, the building, or the customer requires a specific resource or an additional amount of resources.

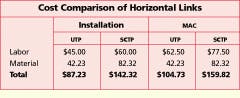

During initial installation of UTP, the placement of a 150-foot length of horizontal cable takes about 30 minutes; the work-area outlet termination requires 15 min; patch-panel termination takes 30 min; and tagging and testing take 15 min. Therefore, the total labor time required for a UTP horizontal link is 90 min. At a labor rate of $30 per hour, this totals $45 per drop.

For a mac, placement of a UTP horizontal cable 150 feet long takes 60 min; the work-area outlet termination takes 20 min; patch panel termination requires 30 min; and tagging and testing take 15 min. The total duration of labor for a UTP horizontal link is 125 min. At a labor rate of $30 per hour, this totals $62.50 per drop, not including order charges.

During initial installation, the placement of an SCTP horizontal cable 150 feet long takes 30 min; the work-area outlet termination takes 25 min; patch panel termination takes 45 min; and tagging and testing take 20 min. (This testing time is an estimate, since no SCTP testing practices are established at this time.) Therefore, the total labor time for an SCTP horizontal link is 120 min. At a labor rate of $30 per hour, this totals $60 per drop.

For a mac, placement of a 150-foot length of SCTP horizontal cable takes 60 min; the work-area outlet termination takes 30 min; patch panel termination takes 45 min, and tagging and testing take 20 min. (This testing time is also an estimate.) The total labor time for an SCTP horizontal link is 155 min. At a labor rate of $30 per hour, this totals $77.50 per drop, not including order charges.

For both initial installations and macs involving SCTP, a premium may be charged for the services of a technician skilled in the termination of the screened medium. Furthermore, the SCTP cable will be on a larger spool and weigh more, and these factors may add a small cost for materials handling.

The components for both UTP and SCTP cabling systems are similar, with the exception that the SCTP system requires screen termination, bonding, and grounding components. All of these products can have a Category 5 level of performance.

Product availability

Many companies in the U.S. structured-cabling market make UTP, but only a few manufacturers make SCTP. Since most customers want an extended warranty for their installations, this dearth of manufacturers creates a limited source for products available to maintain warranty, and these products will get more expensive after initial cutover.

Usually there is more than one certified installer of any cabling system in an area, which creates a degree of competitive bidding for both the initial installation and subsequent upgrades. But because of the limited number of certified installers of SCTP systems, these systems tend to be more expensive. Furthermore, because few SCTP systems are installed in the United States, technicians are often learning SCTP techniques on the first system they install.

As shown in the table above, the total cost for horizontal links for SCTP represents a premium over UTP. During installation the premium is 63.2% and over the life of the cabling system a mac premium of 52.6% applies.

The telecommunications industry has standardized on UTP in the office environment. Studies that measure the amount of emi on UTP cabling systems reveal that emi from common items found in the office workplace has no effect on link performance.

When you are installing networks in a manufacturing or industrial environment, added cost may be expected for the add-itional obstacles found there. If you anticipate such problems, you should investigate other alternatives, such as fiber-to-the-desk.

Since both UTP and SCTP systems can support the same current and foreseeable desktop applications, a user`s preference and comfort level with product reliability are important factors in choosing between the two media.

SCTP appears to have two advantages over UTP--its immunity to emi and RFI and its possibly better attenuation-to-crosstalk ratio (acr). But premium Category 5 UTP cabling can provide nearly the same level of emi and RFI immunity at a fraction of the investment. And SCTP`s increased acr comes at a higher price. Ultimately, it is up to the customer as to whether this feature warrants the higher cost and continued expense of an SCTP cabling system.

One version of screened twisted-pair cable is characterized by a foil shield surrounding the twisted pairs and tinned copper drain wire within a thermoplastic jacket.

Jeffrey A. Lupinacci is a registered communications distribution designer (RCDD) and lan specialist at Brinjac, Kambic and Associates Inc. (Harrisburg, PA), an engineering consulting firm.