This procedure will help you clean up your customers` telecommunications closets.

Tom Suder

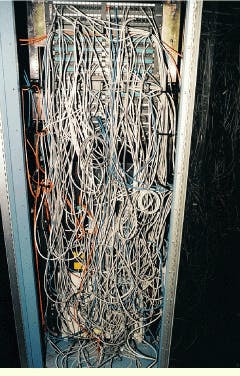

End-users who think the appearance of the telecommunications closet (TC) should take a back seat to all the "more important" issues that surround a network should think again. Shamefully disorganized TCs, with patch cords strewn about, are a pox on the cabling industry, yet are often the sole image that our industry provides to outside observers.

Users do not typically see most of a network`s infrastructure because cabling runs above ceilings, under floors, and through raceways and other devices designed to conceal it. Yet the only thing that keeps onlookers from discovering the rat`s nest in most TCs is the closet door. One glance behind that door and an outsider would find it difficult to believe that the cabling industry has in recent years forged an identity as an indispensable sector of the modern computer network.

The procedure outlined here will take you step-by-step through the cleanup of a telecommunications closet. It has been implemented for Andersen Consulting (see "Andersen Consulting puts patch-cord management plan into action," page 154) and other end-users and is designed to be flexible enough to work in any TC. The plan provides a quick cleanup and does not just lead to a neatly maintained patch-cord management system; it keeps the system organized.

I strongly recommend that an experienced cabling contractor be responsible for cleaning up a patch-cord management system, so this procedure is geared toward this type of individual.

Pre-cleanup organization

Because a TC cleanup is typically performed over a weekend, proper planning for the project is essential. Although we live in a world of pagers and cellular phones, not everyone or everything is available 24 hours a day, so be certain ahead of time that you have the resources and materials you will need to complete the job. Following is an outline of initial steps that will help you determine the scope of the cleanup project:

- Consult with primary contact--Interview the end-user, or customer contact, who is responsible for the patch-cord management system. Ask how the system is managed and ask what problems typically occur. Find out when the TC was last cleaned. Typically, an end-user will have tried to clean the system at least once since it was installed.

- Establish a list of patchers--In large organizations, you may find that a few people do most or all of the patching. Create a list of those individuals for reference throughout the project.

- Develop a management survey--Thoroughly examine the patch-cord management system at least two weeks before the scheduled cleanup. This will provide you with enough time to order additional materials if they are required and to schedule technicians for the weekend work. Review the end-user`s patch-cord management methods and look for problems, such as an inadequate number of horizontal cable managers and vertical cable managers that are too small for open racks. Other environments, especially cabinets, may be too restrictive, so you may have to add custom-made vertical managers to increase management capacity or provide an alternate route for patch cords behind horizontal rails in the cabinet. Wall fields do not always have enough large horizontal cable managers to accommodate the number of cords that travel through them.

- Determine cord-manager requirements--After reviewing the cord managers, determine whether or not additional managers will be required in the future. Typically, patch panels cannot be moved because cables are terminated to them, and the panels are essentially formed in place. So you have to use horizontal managers to work around this obstacle. Usually, you can install additional horizontal managers at the top and bottom of the management system, or replace current managers with larger ones. You will most likely have to replace existing vertical managers with larger ones. Remember that the key to good patch-cord management is for each patch cord to be readily accessible. The more restrictions you put on a cord, the harder it is to route and trace that cord.

-Calculate patch-cord size requirements--Take a patch-cord adjuster kit and 20 feet of 4-pair cable. Cut the cable to determine the optimum length of your patch cords. By applying the PerfectPatch patch-cord adjuster, you can adjust the length of your patch cord by as much as 60%. You can typically use 5- and 7-foot patch cords in racks and cabinets.

-Count patch cords--Count all the patch cords in the management system.

-Draw diagrams--Diagram the management system, indicating the layout of the patch panels and cord managers. If you can, also photograph and videotape the patch-cord management system (always ask the end-user for permission first). Photographs and videotapes are a great visual benefit when you are back in your office. When reviewing the diagrams, photos, or video, indicate problem areas and possible solutions.

- Understand equipment setup--Ask the end-user if the concentrators that you are patching into are segmented for users. You will need to know, for example, if four boards are designated for 10Base-T users and three boards are designated for 100Base-T users, so that you can properly label the ports at the time of cleanup.

- Segment the project if necessary--If you are dealing with multiple patch-cord management systems, break down the project into several parts so you can get a feel for the end-user`s requirements. Doing this will also give the end-user time to get familiar with the cleanup project. Also, once the first segment is complete, you and the end-user can cooperatively refine the process as necessary for the remaining management systems.

-Give initial feedback--After you complete your examination, discuss your preliminary findings with the end-user and follow up with a call and estimated cost report. I recommend providing a time-plus-materials price with a "not-to-exceed" clause. This approach provides a cushion in case you encounter unforeseen obstacles. In addition, you should offer the end-user an exchange of materials such as patch cords and cord-management products. An exchange will lower the end-user`s cost and make your services even more beneficial.

Ducks in a row

Once you have gathered the information you need and you have given the end-user an initial report, it is time to gather the materials needed to complete the project. Following are the essentials of most projects. You will probably find that some jobs have unique needs that mandate additional materials:

- Parts list--Using the diagram, photos, or videotape, thoroughly analyze the management system, rechecking your site visit. Make a list that includes the number of cord managers you will need, additional hardware such as screws or D-rings, and the number of patch cords. Include in your list one-for-one patch-cord replacement. Keep all estimates on the high side because once you start removing patch cords, you have to make do with what you have at the site. If you are a contractor, you should be able to pull a lot of materials from stock.

-Tools--You will need field testers for the media you will work with, as well as a toner, amplifier, and other typical tools for moves, adds, and changes. Carry RJ-45 and RJ-11 type plugs, as well as a crimp tool, because you may have to make a few cords that require different pin configurations than those which you`ll have with your off-the-shelf cords.

- Labels--Purchase a booklet of 1/4-inch round labels (such as Avery labels stock number 05795) or similar colored labels. These small labels are used to indicate the ports on patch panels and blocks into which cords are plugged. This size works well because it does not obstruct numbers printed on panels or blocks. Take some different colored tape and nonerasable markers in case you need to label any cables.

-Aprons--It is a good idea to purchase a two- or three-pocket apron for each technician who will work on the cleanup project. These aprons cost about a dollar apiece at a hardware store and will provide the technicians easy access to the patch-cord adjuster pieces at the job site.

- Unshielded twisted-pair patch cords--Take at least as many patch cords as the end-user has in the system so you can provide a one-to-one swap. You should already have determined patch-cord sizes in your preliminary research. The alternative to a one-to-one swap is to have an additional person on-site to untangle the mess of cords that is removed during the cleanup. Untangling is usually a time-consuming process and is often rushed when performed at the site. The patch-cord exchange actually lowers your labor cost because you can have an employee untangle the mess at the office when time permits.

- Fiber patch cords--Because of the cost and the small number of fiber patch cords in the system backbone, a one-to-one exchange of these cords is not usually necessary. However, it is wise to bring a few fiber patch cords in case damage occurs during the project.

- Cleanup schedule--Give yourself at least two weeks to prepare, and schedule the project to take place over a weekend. Typically, a project will start on a Friday and continue through Saturday and possibly Sunday. Make it clear in the schedule and to the end-user that you will be in on Friday to start labeling and, by Friday evening, you will start removing patch cords. Solidify plans to notify network users well in advance that the network will be down on Friday night, Saturday, and possibly Sunday. This is important because if there is a conflict, you must know about it in advance to accommodate it, if possible. If a few individuals have high-priority needs, plan to bring up their computers and telephones first, once your installation is complete.

- Access plan--Ensure your access to the customer site during the scheduled time. Arrange to park your vehicles for an extended period. Parking can be a problem on weekends and after 9:00 PM in some cities. Also confirm your access to all involved areas of the building, including equipment rooms, closets, and office areas. Require that all security codes be available to you and your customer contact.

- Technician schedule--Inform your technicians that this will be a weekend job, and I recommend that you use your best technicians. This is one job in which you cannot afford to spend time instructing and coaching your team at every step.

Getting the job done

When you arrive at the job site on Friday to begin the cleanup, you should be well-prepared, thanks to your advance planning. You have thoroughly analyzed the patch-cord management system, developed a plan by which you will replace the existing patch cords with new ones, gathered the appropriate number and quality of technicians around you, and brought all necessary materials with you. Here are the procedures you will go through to complete the project:

- Finalize the checklist--Make sure the network users know that their equipment will be down--perhaps through Sunday. Also, get from the end-user the workstation locations of those network users who might be in during the cleanup period, as well as a list of the critical network components such as servers and routers. You will need this list to ensure that critical components are the first to be brought back up. Finally, double-check to make sure that you will be granted proper access and parking privileges throughout the weekend.

- Label the ports--Affix colored sticker dots at the ports on patch panels and blocks that have cords plugged into them so you can identify the proper ports once you have removed the existing patch cords. I use a color scheme that lets me identify ports of different type and priority. For instance, red dots signify critical network components, blue dots signify users who will be working during the cleanup, yellow dots signify 10Base-T ports, and green dots signify 100Base-T ports. Remember that when you affix these dots, the patch field is highly congested. So take time to review the dots once they are all affixed to ensure that all ports are properly labeled.

- Sort the patch-cord adjusters--Separate the patch-cord adjusters. Then place the bases and the covers into separate pockets of your apron.

- Remove the patch cords--Unplug all the patch cords, starting at the top of the panel or block and working your way toward the bottom. Remove the cords in large groups, rather than one at a time. Removing them one at a time increases the likelihood of snagging and breaking the modular-plug cord tips and increasing labor time.

- Adjust the new patch cords--Remove the patch-cord adjuster base and cover from your pouch and clip them onto a patch cord. Adjust the cord to the length required for that patch, then clip another patch-cord adjuster onto the cord. This process takes a few seconds and is necessary to prevent future maintenance problems.

- Make the connections--Patch all cords back into the appropriate ports, using the colored dots as your guide.

- Test the connections--Have the end-user try to use some computers while you are still patching to see if the computers can access critical locations. The end-user will determine the number of network connections to be checked, but typically, 10% is sufficient.

Now that the repatching is done and the TC is cleaned up, you must implement a maintenance plan to ensure that the aesthetic appeal lasts. Listed below are several ingredients for a successful patch-cord maintenance plan:

-Monday morning follow-up--Send one of the technicians who was involved in the cleanup to the site on Monday morning. If you cannot do that, at least have one of these technicians on call that day. In my experience, I have found that typically fewer than 2% of the patches are done incorrectly, and most of those misplacements can be traced to a color dot`s being incorrectly placed on a port.

- Training--You must train your customers. Lack of training is detrimental to the life cycle of the patch-cord management system. Instruct the patchers--whom you identified earlier--in how to use patch-cord adjusters, which should take about three minutes. Emphasize that adjusting the patch cord`s length is essential each time the customer performs a patch.

-House calls--Stop by the site after six months, then again after a year, to review system management. As long as the task of using the patch-cord adjuster on each cord is implemented, the system`s appearance and performance will remain steady.

- Before-and-after photos--Display before-and-after photos, if available, to remind personnel working in the TC about the former rat`s nest and to show them that with minimal effort, they can maintain the integrity of the patch-cord management system.

Contractors, manufacturers, and end-users should work together toward the day when perfectly arranged patch-cord management systems that are displayed in trade-show booths and print advertisements will actually be true-to-life depictions.

This cabinet restricts the space in which patch-cord slack can be managed. Too much restriction can harm a patch-cord manage-ment system.

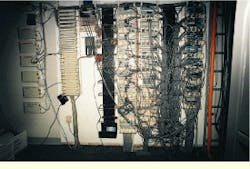

The use of 8-foot patch cords in this 110-block wall field left excessive, unmanaged slack.

Andersen Consulting`s Jay Feliciano demonstrates the ease with which he can trace a patch cord, now that he has successfully completed the patch-cord management program.

Andersen Consulting puts patch-cord management plan into action

Andersen Consulting, a global management and technology consulting firm, employs more than 53,000 professionals and earns more than $6 billion annually. The firm`s mission is to help clients from a wide range of industries achieve success by aligning people, processes, and technology with sound strategy to achieve optimal business performance.

As a rule, Andersen Consulting looks outside traditional industry borders to expand and improve its business. That approach is in line with the recent steps that one division of the company--The Financial Ideas Exchange--took to upgrade the performance and aesthetics of its patch-cord management system. The division is located in the heart of Manhattan and was dealing with a patch-cord management system that was as tough to negotiate as New York City traffic and is typical of our industry; it looked like a rat`s nest.

Andersen dealt with two Category 5 management structures. One was a cabinet with patch panels and a concentrator with 100Base-T and 10Base-T boards, and the other was a 110 wall field with more than 350 patch cords interfacing between the horizontal cabling system and the network equipment. The Andersen Consulting Technology team, led by Jay Feliciano, constantly faced loose connections, excessive time spent tracing patch cords, and the everyday embarrassment of unattractive management systems. The team had repeatedly attempted to clean up these systems, using traditional management techniques that did not work for them.

Finally, Feliciano decided to try the PerfectPatch, a device that provides adjustability to each patch cord and custom fits the cord in seconds.

"It seems like such a simple concept; you really can`t believe its performance until you see it for yourself," Feliciano says. "Now all I have to do is look at the management system to see if the people on my staff are using the PerfectPatch on each cord. And I know my system looks great and functions well."

Tom Suder is vice president of PerfectPatch (Sterling, VA), which manufactures the PerfectPatch patch-cord adjuster.