Cable blocks prevent aerial cable sag and help reduce the risk of damage during placement and lashing.

Douglas Clemens

In the 1950s, when suburbia was still in its infancy and Ma Bell was a household name, telecommunications crews working on the outside plant used simple devices known as cable blocks to place and support copper cable from pole to pole with greater ease and efficiency.

Today, advanced versions of this device are designed and engineered especially for coaxial, fiber-optic, and hybrid fiber/coaxial cable (hfc), all of which have much smaller diameters than traditional copper cable. Cable blocks are in strong demand as telecommunications crews continue to place mile upon mile of new cable to satisfy the voracious appetite of industry and consumers for ever-increasing voice, video, and data transmissions.

The cable block is basically an aerial hanger that attaches to an overhead steel messenger strand that runs from pole to pole. It typically includes a bidirectional locking mechanism and one or more pulleys, or rollers, that temporarily support and protect the telecommunications cable before it is lashed to the messenger strand. Without such support, a great looping sag would occur along the length of cable as it is raised into position between utility poles. Sagging cable is difficult to place and can easily be damaged during placement.

Relieves stress on cable

For the sake of comparison, imagine telecommunications cable as a strand of cooked spaghetti that you suspend in the air by holding one end in each hand. When your hands are close together, although the strand sags in the middle, there is very little stress placed upon it. But as you pull your hands apart to straighten the strand, the stress increases. Before long, the strand stretches and then breaks as its tensile strength is exceeded. The effect of extreme stress on telecommunications cable is much the same.

Raising and pulling unsupported cable places enormous stress on the delicate coaxial or fiber-optic wire bundles located beneath the cable`s protective outer cover. Beyond a critical point, stress can produce significant cable damage, resulting in poor signal transmission or the total inability of cable to transmit electronic signals.

Cable blocks relieve the stress placed on cable as it is pulled and suspended between poles prior to lashing. A craftsperson working from an aerial bucket truck or using a manual lifter (often referred to as a layup stick) hangs the cable block from the messenger strand and locks it into place. Most cable blocks are designed with a bidirectional locking mechanism that prevents the blocks from sliding backward on the messenger strand as they pull cable into position for lashing. When lashing forward and in the opposite direction, the blocks slide forward toward the pole further down the line, as required during cable lashing.

Placing cable across the span

To ensure proper cable placement, cable blocks are hung approximately 15 to 20 feet apart from each other. The actual spacing between cable blocks depends on the size and weight of the cable to be placed. Single-wire coaxial cable, which is widely used by the cable-TV industry, has an outside diameter of less than 1 inch, including its protective foam cover. Fiber-optic cable is typically 1/2 to 3/4 inch in diameter; its protective innerduct is generally not greater than 11/4 inches in diameter.

Once all the cable blocks are in place, the craftsperson either places the cable onto the pulleys while standing in an aerial bucket or pulls the cable into position across the block`s pulleys. The use of pulleys or rollers with smooth, non-marring edges ensures that cable or innerduct is not damaged as it is being pulled into position.

During lashing, forward block movement is initiated by a cable-block pusher, which is positioned between the cable block and the cable-lashing machine. The pusher is a slotted tubular device that maintains proper cable lead between the lasher and the cable block. It is locked onto the messenger strand by two rotatable sleeves or locking pins that are located at each end of the pusher. The lasher is a sophisticated machine that spirals strong stainless steel wire around the cable and its supporting messenger strand. It can also be used to lash newly placed cable to existing aerial cable--a procedure called overlashing.

As the lasher is pulled forward, the cable-block pusher moves before it, hitting the block. The block`s locking mechanism is automatically released on impact, allowing the block to slide forward toward the next block on the messenger strand. Lashing continues in this manner until all the blocks have been pushed to the end of the span, and the equipment is removed. The pusher and lasher are then installed on the next span where additional blocks are already in place, supporting the telecommunications cable that is to be lashed.

Blocks for every application

Cable blocks come in various shapes and sizes and are configured with one or more pulleys. They are designed to meet the specific cable placing needs of coaxial, fiber-optic, and hfc cable, as well as copper cable. In addition to standard cable blocks, some overlash blocks allow the overlashing of fiber-optic cable to existing copper or fiber-optic cable bundles up to a maximum 2-inch diameter.

Cable blocks used for supporting coaxial or fiber-optic cable are available with 1- or 13/8-inch diameter pulleys. These cable blocks are especially useful in situations that require a higher level of security, such as passage over roadways or waterways.

Coaxial and fiber-optic cables are lightweight and not very pliable. Blocks for both cable types are designed with a locking gate to prevent the cable from jumping out of the pulley.

Broadband applications

Among the newest products on the market today are hfc cable blocks that are compatible with all broadband cable currently in use. Blocks are available to handle from two to as many as eight combinations of coaxial and fiber-optic cable, as well as innerduct.

hfc cable blocks were developed with the aid of field engineering specialists in anticipation of the widespread industry need to deliver greater broadband capacity for voice, video, and data transmission.

Coaxial and optical fiber are the cable types most widely used in today`s new aerial construction. Thicker copper cable--consisting of as many as 3600 pairs of conductor wire--continues to be placed throughout the country, but to a more limited extent than in the past. The simple, sturdy blocks used for supporting copper cable have changed very little from earlier models that were employed in the 1950s.

The pulleys on copper cable blocks are much larger than those found on those used with coaxial and fiber-optic cable. They`re built to handle copper cable bundles up to 5 inches in diameter. There are special blocks for smaller-diameter copper cable as well.

Meeting future needs

The future of cable blocks appears secure as outside-plant managers continue to view aerial cable lashing as the technique of choice for overhead cable construction. Further refinements in cable-block design will make these essential devices even more versatile and economical to use.

One block, for example, does not have a messenger-strand locking mechanism. Instead, it is engineered with a gritty, non-skid surface that helps it resist movement on the strand during cable placement. The block can be attached to strands measuring 1/4 to 3/8 inch in diameter. The block is designed as an affordable approach for new or rebuild aerial construction. It permits overlashing of coaxial, fiber-optic, and copper cable bundles up to 2 inches in diameter. A lever-actuated keeper bar, which is built into the unit, encloses the cable to prevent it from jumping out of the pulley. The block`s zinc-plated steel frame is designed for optimum strength-to-weight ratio, making it extremely durable.

The information superhighway could not exist without the miles of telecommunications cable that stretch across the land. Placing that cable would be a much more difficult and costly task were it not for cable blocks, which provide reliable support across the span.

In this hybrid fiber/coaxial-cable block configuration from General Machine Products Co., the four rollers on top have 13/8-inch diameters while the four on the bottom have 1-inch diameters.

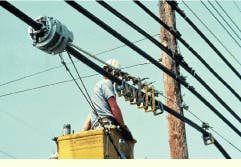

a) A cable block (left) attached to a messenger strand supports a cable as a lashing machine (right) heads toward it. The lasher is wrapping a stainless-steel wire around the cable and messenger strand.

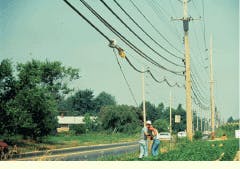

b) A crew pulls a lasher across a span of unlashed cable. Sliding before the lasher are several cable blocks that the cable-block pusher has released from their locked positions on the messenger strand.

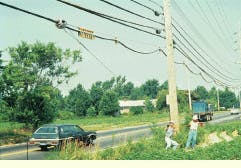

c) The lashing of one span of cable between utility poles is almost finished. The cable to the left of the lasher is now neatly lashed to the messenger strand.

d) The cable blocks, which previously supported the unlashed cable, have all been pushed to the end of the span.

e) At the end of one span of lashed cable, the craftsperson removes the cable blocks to allow lashing around the pole.

Douglas Clemens is vice president of sales and marketing at General Machine Products Co. Inc. (Trevose, PA), www.gmptools.com.