Cable management software solutions evolve

As software sharpens, new partnerships with cable manufacturers arise.

As “intelligent” physical-layer management systems gain traction among large-scale users, the software that enables these systems’ intelligence is sharpening while the hardware becomes more robust.

Cable management software solutions have evolved to the next step. The latest incarnations of these solutions are designed so that intelligent patching, and not simply the active gear, is more integrated to the overall network manager’s view. They are designed to provide better mapping of every connection to every port in the network, allowing for a refined view of connectivity.

Until recently, network management software would provide information technology workers with a logical view of the network’s devices, but not present cable connection information. With intelligent patching systems, today’s solutions can open up the view of the physical layer connectivity to help network administrators manage their networks. Such vision allows network managers to quickly respond to network changes or issues, keeping it running more smoothly and avoiding downtime. It also adds proactive functionality, such as the ability to plan work orders for deploying network assets in a controlled manner, and to control the implementation of troubleshooting or ongoing operational activities in a more effective way.

“They (cable management software) answer the question, ‘How do you trace the cabling that has been installed?’” says Michael Pula, lead business development manager for Panduit Corp.’s (Tinley Park, IL; www.panduit.com) managed network solutions group. “These are the veins that carry the blood supply of datacom equipment.”

The solutions are being sought by most major enterprise end users seeking intelligent infrastructure management, improved security of the IT infrastructure, ease of moves, adds and changes (MACs,) and better management of active devices and the physical layer.

“Most end users have no documentation whatsoever. It’s now at a point where so much time is spent troubleshooting their network,” says Jamie Roux, president of the manufacturer’s agent DataStrait Networks Inc. (Minneapolis, MN; www.datastrait.com).

More recently, regulatory compliance with the Sarbanes-Oxley Act of 2002 has become an important driver. The law, which introduced highly significant legislative changes to financial practice and corporate governance regulation, has created a need for a whole new level of network security and documentation.

As a result, enterprise end users are making their voices heard as they seek out new and better products. Consequently, today’s software and hardware differs dramatically from the first generation of these products. The solutions demonstrate a greater connection between the software and the physical layer.

“Since we first introduced our PatchView for the Enterprise software solution, over six years ago, there has been a constant evolution of the product,” says Liam Galin, outgoing president and CEO of RiT Technologies. (See related story, page 45.) “The feedback we have received from our installed base has resulted in continuous improvements not only in functionality but also in ease of use.”

Here are just a few of the recent developments in cable management:

• iTRACS (Chicago, IL; www.itracs.com) Infrastructure Manager software has been specifically designed to function in partnership with iTRACS-enabled hardware, which is manufactured by industry OEMs. The software intelligently suggests the best connectivity routes, a feature called auto-routing. It also allows simultaneous access by a spectrum of department representatives, including help desk, planning, network administration, supervision and technicians. With iTRACS IM, modules that were previously sold separately have been integrated into one package. These include a work order system, virtual wiring racks with scalable graphics, detailed circuit trace, utilization reports, and iDiscover-providing auto-discovery of active network devices and their physical location on floor plan graphics.

• SYSTIMAX Solutions (Richardson, TX; www.systimax.com), now offers iPatch Rack Manager, which is installed in each rack to communicate with and manage iPatch copper and fiber panels. It maintains a database of current patch connections and reports status changes to the network administrator, and assists technicians in performing scheduled MACs. The SYSTIMAX iPatch System Manager Software Version 4.0 is designed to provide greater vision and control over the entire communication network. It adds links to network management systems, such as HP OpenView, that let network managers receive alarms from the iPatch System to query iPatch System Manager for viewing CAD floor plans that show the location of network equipment, and to obtain physical-layer circuit traces. iPatch System Manager lets customers specify, on a per-circuit basis, whether Simple Network Management Protocol (SNMP) alarms will be generated when a cabling change occurs.

• RiT Technologies (Mahwah, NJ; www.rittech.com) offers PatchView, which combines auto-connection discovery of copper and fiber components and real-time physical layer analytics that enable complete visibility of the network’s foundation. It is a standards-based, end-to-end structured cabling system with intelligent patch panels and software that provide a complete view of physical layer voice (IP phones or PBX support) and data connectivity and its relation to the logical layers. The Web-based application, combined with the ability to define event-driven alerts to pagers, text messages or cell phones, is designed for simple and effective remote network management of dispersed organizations.

Hardware developments

As the software evolves, some new partnerships are occurring between cable management software providers and cabling product manufacturers. Most major cabling vendors appear to be aligning with one or more intelligent physical layer management solutions manufacturers as they seek to offer differentiated product lines.

iTRACS is an open, non-proprietary system that can be retrofit to installed patch panels and switches, and used in interconnect architecture as well as cross-connect. Through licensing agreements, five manufacturers now produce hardware that enables instantaneous updates to the software records. These OEMs provide customers a choice of hardware manufactured by AMP Netconnect (Harrisburg, PA; www.ampnetconnect.com), ITT Industries (Tarrytown, NY; www.ittnss.com), Ortronics (New London, CT; www.ortronics.com), Molex Premise Networks (Downers Grove, IL; www.molexpn.com) and The Siemon Company (Watertown, CT; www.siemon.com).

iTRACS Infrastructure Manager was released to OEMs in April as a controlled rollout to select customers, and the final product was made available in May. It is now available through AMP Netconnect, with other channels expected to open over the next few months. iTRACS Standard and Advanced Edition software are available through iTRACS.

Using iTRACS Advanced Edition software, the manufacturers have differentiated themselves from one another by coming up with their own solutions and improvements. They manufacture their own patch panels and patch cords-copper and fiber-to exceed various TIA specifications. They control manufacturing methods, materials, and QA control. These methods vary according to manufacturer. The OEMs purchase circuit boards from one to three sources and build the analyzers and analyzer cords. They then quote and design the network for the customer.

“The OEMs come to us, and want a product that is aligned around the needs of the guy managing the closet,” says Frank Dickman, special projects director, iTRACS Corp.

Specific end users

The new products from these partnerships have been targeted for specific end users, and built to the specs of those users. In some cases, for example, Power over Ethernet (PoE) and WiFi management capabilitiesare being added to the hardware. The software is adding features such as auto-routing, which suggest the best cable route for an installation.

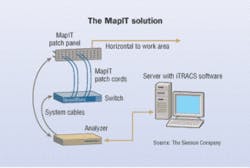

MapIT, The Siemon Company’s product, for example, is designed to help manage and protect an enterprise end user’s IT assets. The solution features iTRACS sensor technology embedded in HD 6 patch panels and MC 6 modular cords. The solution monitors physical layer connections and tracks any active device connected to the network. If someone with an unauthorized device attempts to get on the network, MapIT can take action by blocking access at the switch level and reporting the occurrence.

“We’ve been looking at the technology for a few years,” says Frank Velleca, market manager for The Siemon Company. “The first generation of hardware was not robust enough to provide warranties.”

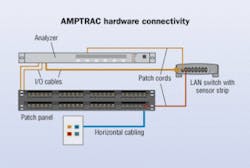

AMPTRAC is AMP Netconnect’s hardware product in this realm. When used in conjunction with AMPTRAC Connectivity Management System, iTRACS IM software enables real-time monitoring and reporting of the physical network connections and devices. Tony Beam, director of business development, says AMP Netconnect expects wider market acceptance with the introduction of iTRACS IM.

“Our latest system releases have all offered AMPTRACcapabilities, such as our XG (10 Gbits/sec) copper and fiber systems, our new MRJ21 Modular Copper Connectivity System, our MPO Modular Fiber System, as well as existing Cat 5e, Cat 6 and fiber systems,” says Beam.

iTRACS’ competitors offer proprietary systems for cross-connect architecture.

RiT Technologies now has four partners who integrate the RiT technology into their own solutions. There are OEM agreements with Panduit, which sells PatchView under the PanView brand name, and with Brand-Rex (Scotland; www.brand-rex.co.uk), which markets the product in Europe under the SMARTPatch name. Belden CDT Inc. (St. Louis, MO; www.beldencdt.com) sells IntelliMAC Plus, and ADC Krone (Eden Prairie, MN; www.adc.com) positions the solution within its PremisNET line. All RiT’s strategic partners embed RiT intelligent technology into their patch panels, allowing them to run RiT’s PatchView management software.

“Our customers came to us asking to use our technology with their choice of an end-to-end cabling system,” says Galin. “Therefore, our OEM agreements allow our loyal and valued clients to continue to use the RiT intelligent physical layer management system technology they have used for years, but now also to be able to choose the structured cabling system of their choice.”

Like RiT, Systimax Solutions’ components, hardware, and software are all developed in-house. Systimax software is updated about every six months with a new set of features. The latest update is designed to automate more data entry operations, minimizing the amount of error that can be introduced to the system’s database.

This year, Systimax has introduced two optical-fiber shelves, one for SC fiber interfaces and the other for LC fiber interfaces. The system also features a new controller, Rack Manager Plus, which is designed to make it easier to configure the system. The architecture communicates with the patch panels, collects information and provides it to the cable management software. Enterprise end users can customize the solution to their needs, specifying patch panels and software components.

Michael German, technical director, North American region, for Systimax Solutions, argues that the system can be used in retrofit situations, requiring only that the contractor install a new intelligent patch panel, which can use the existing patch cords.

“Our goal is to automate the data entry process to the point where you can answer everything through the use of the existing database information, or through communication with existing hardware,” says German.

Just who is seeking cable management software?As “intelligent” physical-layer management systems gain traction among large-scale users, the software that enables these systems’ intelligence is sharpening while the hardware becomes more robust.

Cable management software solutions have evolved to the next step. The latest incarnations of these solutions are designed so that intelligent patching, and not simply the active gear, is more integrated to the overall network manager’s view. They are designed to provide better mapping of every connection to every port in the network, allowing for a refined view of connectivity.

Until recently, network management software would provide information technology workers with a logical view of the network’s devices, but not present cable connection information. With intelligent patching systems, today’s solutions can open up the view of the physical layer connectivity to help network administrators manage their networks. Such vision allows network managers to quickly respond to network changes or issues, keeping it running more smoothly and avoiding downtime. It also adds proactive functionality, such as the ability to plan work orders for deploying network assets in a controlled manner, and to control the implementation of troubleshooting or ongoing operational activities in a more effective way.

“They (cable management software) answer the question, ‘How do you trace the cabling that has been installed?’” says Michael Pula, lead business development manager for Panduit Corp.’s (Tinley Park, IL; www.panduit.com) managed network solutions group. “These are the veins that carry the blood supply of datacom equipment.”

The solutions are being sought by most major enterprise end users seeking intelligent infrastructure management, improved security of the IT infrastructure, ease of moves, adds and changes (MACs,) and better management of active devices and the physical layer.

“Most end users have no documentation whatsoever. It’s now at a point where so much time is spent troubleshooting their network,” says Jamie Roux, president of the manufacturer’s agent DataStrait Networks Inc. (Minneapolis, MN; www.datastrait.com).

More recently, regulatory compliance with the Sarbanes-Oxley Act of 2002 has become an important driver. The law, which introduced highly significant legislative changes to financial practice and corporate governance regulation, has created a need for a whole new level of network security and documentation.

As a result, enterprise end users are making their voices heard as they seek out new and better products. Consequently, today’s software and hardware differs dramatically from the first generation of these products. The solutions demonstrate a greater connection between the software and the physical layer.

“Since we first introduced our PatchView for the Enterprise software solution, over six years ago, there has been a constant evolution of the product,” says Liam Galin, outgoing president and CEO of RiT Technologies. (See related story, page 45.) “The feedback we have received from our installed base has resulted in continuous improvements not only in functionality but also in ease of use.”

Here are just a few of the recent developments in cable management:

• iTRACS (Chicago, IL; www.itracs.com) Infrastructure Manager software has been specifically designed to function in partnership with iTRACS-enabled hardware, which is manufactured by industry OEMs. The software intelligently suggests the best connectivity routes, a feature called auto-routing. It also allows simultaneous access by a spectrum of department representatives, including help desk, planning, network administration, supervision and technicians. With iTRACS IM, modules that were previously sold separately have been integrated into one package. These include a work order system, virtual wiring racks with scalable graphics, detailed circuit trace, utilization reports, and iDiscover-providing auto-discovery of active network devices and their physical location on floor plan graphics.

• SYSTIMAX Solutions (Richardson, TX; www.systimax.com), now offers iPatch Rack Manager, which is installed in each rack to communicate with and manage iPatch copper and fiber panels. It maintains a database of current patch connections and reports status changes to the network administrator, and assists technicians in performing scheduled MACs. The SYSTIMAX iPatch System Manager Software Version 4.0 is designed to provide greater vision and control over the entire communication network. It adds links to network management systems, such as HP OpenView, that let network managers receive alarms from the iPatch System to query iPatch System Manager for viewing CAD floor plans that show the location of network equipment, and to obtain physical-layer circuit traces. iPatch System Manager lets customers specify, on a per-circuit basis, whether Simple Network Management Protocol (SNMP) alarms will be generated when a cabling change occurs.

• RiT Technologies (Mahwah, NJ; www.rittech.com) offers PatchView, which combines auto-connection discovery of copper and fiber components and real-time physical layer analytics that enable complete visibility of the network’s foundation. It is a standards-based, end-to-end structured cabling system with intelligent patch panels and software that provide a complete view of physical layer voice (IP phones or PBX support) and data connectivity and its relation to the logical layers. The Web-based application, combined with the ability to define event-driven alerts to pagers, text messages or cell phones, is designed for simple and effective remote network management of dispersed organizations.

Hardware developments

As the software evolves, some new partnerships are occurring between cable management software providers and cabling product manufacturers. Most major cabling vendors appear to be aligning with one or more intelligent physical layer management solutions manufacturers as they seek to offer differentiated product lines.

iTRACS is an open, non-proprietary system that can be retrofit to installed patch panels and switches, and used in interconnect architecture as well as cross-connect. Through licensing agreements, five manufacturers now produce hardware that enables instantaneous updates to the software records. These OEMs provide customers a choice of hardware manufactured by AMP Netconnect (Harrisburg, PA; www.ampnetconnect.com), ITT Industries (Tarrytown, NY; www.ittnss.com), Ortronics (New London, CT; www.ortronics.com), Molex Premise Networks (Downers Grove, IL; www.molexpn.com) and The Siemon Company (Watertown, CT; www.siemon.com).

iTRACS Infrastructure Manager was released to OEMs in April as a controlled rollout to select customers, and the final product was made available in May. It is now available through AMP Netconnect, with other channels expected to open over the next few months. iTRACS Standard and Advanced Edition software are available through iTRACS.

Using iTRACS Advanced Edition software, the manufacturers have differentiated themselves from one another by coming up with their own solutions and improvements. They manufacture their own patch panels and patch cords-copper and fiber-to exceed various TIA specifications. They control manufacturing methods, materials, and QA control. These methods vary according to manufacturer. The OEMs purchase circuit boards from one to three sources and build the analyzers and analyzer cords. They then quote and design the network for the customer.

“The OEMs come to us, and want a product that is aligned around the needs of the guy managing the closet,” says Frank Dickman, special projects director, iTRACS Corp.

Specific end users

The new products from these partnerships have been targeted for specific end users, and built to the specs of those users. In some cases, for example, Power over Ethernet (PoE) and WiFi management capabilitiesare being added to the hardware. The software is adding features such as auto-routing, which suggest the best cable route for an installation.

MapIT, The Siemon Company’s product, for example, is designed to help manage and protect an enterprise end user’s IT assets. The solution features iTRACS sensor technology embedded in HD 6 patch panels and MC 6 modular cords. The solution monitors physical layer connections and tracks any active device connected to the network. If someone with an unauthorized device attempts to get on the network, MapIT can take action by blocking access at the switch level and reporting the occurrence.

“We’ve been looking at the technology for a few years,” says Frank Velleca, market manager for The Siemon Company. “The first generation of hardware was not robust enough to provide warranties.”

AMPTRAC is AMP Netconnect’s hardware product in this realm. When used in conjunction with AMPTRAC Connectivity Management System, iTRACS IM software enables real-time monitoring and reporting of the physical network connections and devices. Tony Beam, director of business development, says AMP Netconnect expects wider market acceptance with the introduction of iTRACS IM.

“Our latest system releases have all offered AMPTRACcapabilities, such as our XG (10 Gbits/sec) copper and fiber systems, our new MRJ21 Modular Copper Connectivity System, our MPO Modular Fiber System, as well as existing Cat 5e, Cat 6 and fiber systems,” says Beam.

iTRACS’ competitors offer proprietary systems for cross-connect architecture.

RiT Technologies now has four partners who integrate the RiT technology into their own solutions. There are OEM agreements with Panduit, which sells PatchView under the PanView brand name, and with Brand-Rex (Scotland; www.brand-rex.co.uk), which markets the product in Europe under the SMARTPatch name. Belden CDT Inc. (St. Louis, MO; www.beldencdt.com) sells IntelliMAC Plus, and ADC Krone (Eden Prairie, MN; www.adc.com) positions the solution within its PremisNET line. All RiT’s strategic partners embed RiT intelligent technology into their patch panels, allowing them to run RiT’s PatchView management software.

“Our customers came to us asking to use our technology with their choice of an end-to-end cabling system,” says Galin. “Therefore, our OEM agreements allow our loyal and valued clients to continue to use the RiT intelligent physical layer management system technology they have used for years, but now also to be able to choose the structured cabling system of their choice.”

Like RiT, Systimax Solutions’ components, hardware, and software are all developed in-house. Systimax software is updated about every six months with a new set of features. The latest update is designed to automate more data entry operations, minimizing the amount of error that can be introduced to the system’s database.

This year, Systimax has introduced two optical-fiber shelves, one for SC fiber interfaces and the other for LC fiber interfaces. The system also features a new controller, Rack Manager Plus, which is designed to make it easier to configure the system. The architecture communicates with the patch panels, collects information and provides it to the cable management software. Enterprise end users can customize the solution to their needs, specifying patch panels and software components.

Michael German, technical director, North American region, for Systimax Solutions, argues that the system can be used in retrofit situations, requiring only that the contractor install a new intelligent patch panel, which can use the existing patch cords.

“Our goal is to automate the data entry process to the point where you can answer everything through the use of the existing database information, or through communication with existing hardware,” says German.

BRIAN MILLIGAN is senior editor for Cabling Installation & Maintenance.