The 2021 Cabling Innovators Awards, sponsored by Sumitomo Electric Lightwave, honors products, programs, and applications that distinguish themselves from previous offerings. Recipients of Silver level Innovators Awards have demonstrated marked improvement over previous technologies, methods, and approaches. Following are the Cabling Innovators Silver Awards recipients, described in their own words.

AEM: MMVNA-200 Mixed Mode Multi-Port Vector Analyzer

The MMVNA-200 is a multi-port vector network analyzer capable of simultaneously measuring multiple ports and their interdependency. The small, portable 8-port form-factor makes MMVNA-200 easy to integrate in the cable and connector manufacturing environment, and represents a significant cost savings for this level of port density compared to other offerings.

Measuring all possible combinations of RF S-parameters across all ports within a sweep lasting less than 10 seconds, MMVNA-200 greatly reduces test time over other RF test systems. Additionally, multiple test ports eliminate the need of connecting and disconnecting different test fixtures repeatedly. No external RF switch matrix is required, further simplifying the test setup.

MMVNA-200 is uniquely capable of performing dual-ended testing using two independent MMVNA-200 instruments synchronized over the communication-channel under test. This feature makes it ideal for far-field measurements and cable measurements.

In addition to RF measurements, MMVNA-200 also performs DC measurements, ensuring proper end-

to-end connectivity of the DUT and measuring DC resistance when required. This is an important feature for DUTs where many failures happen due to improper connectivity rather than RF performance. VNA Manager is a required companion software utility that facilitates control of the analyzer including customization of the Autotest through S-parameter based settings.

The system is IP addressable enabling remote view of test data across geographical locations. While MMVNA-200 measures hundreds of different S-parameters in every sweep within seconds, yet it enables focusing on critical parameters by allowing flexible configuration, and easy-to-understand PASS/FAIL results. Results for mixed-mode and single-ended results are displayed and tools for zooming and filtering of results are available for in-depth analysis. These features make MMVNA-200 one of the most versatile RF analyzer for the engineers interested in deep-dive, and at the same time fast and easy for the operators.

A large number of test applications can be supported by user configurable parameters and test limits. These are several built-in configurations for widely used test applications such as automotive single-pair Ethernet test.

Chatsworth Products: ZetaFrame Cabinet

Increasing cabinet densities have changed the way the rack space is utilized. In keeping up with how the networking and server equipment industry is also evolving, it was important to consider a strong and reliable cabinet frame. Newer compute hardware include additional processors and memory components as part of their configuration, which not only increase power demand, but increase the weight of the computer and the amount of heat that must be dissipated from the computer. So, besides reliable power distribution, to support and protect advanced equipment, a data center rack must feature much higher load ratings to hold additional weight, improved airflow management features so more cool air flows through the rack and enhanced cable management to allow for more intuitive and flexible moves, adds and changes. Another important fact is the need for high static load ratings and rolling loads since more data centers have been utilizing third-party integrators. Often referred to as “rack and roll,” these integrators populate cabinets with compute, power, and cabling, then transport fully loaded cabinets to the data center space where they are rolled into position and quickly brought online. ZetaFrame was engineered to allow for exceptional 5,000 lb (2268 kg) static load (on leveling feet) and 4,000 lb (1814 kg) dynamic load (on casters), which will support new equipment for years to come.

Corning Optical Communications: Everon Solutions Launch

From the smallest office to the largest stadium, Corning Everon™ Network Solutions offers the Enterprise a powerful new way to network so buildings are ready for tomorrow’s network challenges, today.

Built on optical fiber technology, wired and wireless connectivity now live on a single network, reducing costs at installation and over the lifetime of the building. With new technology emerging all the time—all with their own unique data and power requirements—a flexible solution that can scale into the future is imperative. Whether your LAN application is in a small medical clinic, a multi-terminal airport or even a large campus of multiple buildings, all of the components of our solution are proven to work together seamlessly.

Everon has 4 main components that connect to tell a holistic network story:

Campus Backbone Local Area Network (LAN) -- Optical network infrastructure solutions that interconnect building LAN to campus core

Building Backbone Local Area Network (LAN) -- Fiber Optic LAN for your building network infrastructure; connect telecommunications closets, equipment rooms, and entrance facilities

Horizontal Local Area Network (LAN)

Fiber to the Edge of your network. Complete optical networking solutions for wired and wireless connectivity

In-Building Cellular Solutions

Carrier approved wireless coverage and capacity solutions for enterprise networks

More Capability. Technologies like 5G, WiFi6 and IOT require much more network capacity. Our streamlined infrastructure is designed to handle tomorrows technology, today.

Faster Deployments. Solutions designed to deliver faster installations and quicker system turn up times. Backed by an extensive engineering team, we design our solutions with your network in mind.

Cost Savings. Everon™ Network Solutions eliminates the need to run multiple separate networks for data, cellular, and Wi-Fi. It can offer savings of up to 30 percent on materials and labor at installation, plus up to 50 percent on future upgrades.

A Trusted Solution. The world trusts our fiber optic technology to connect people globally over a billion kilometers of Corning optical fiber and to connect millions of homes and enterprises. You can too.

And customers are seeing the results. This new end-to-end network solution eliminates dedicated layers of infrastructure; reducing complexity and improving scalability resulting in:

- Up to 70% less cable

- 80% less IT closets

- 50% less cable tray

- Less cellular equipment with some solutions

These optical networks and fiber-based cellular solutions deliver more bandwidth and performance. Technologies like 5G, Wifi6, and IOT require exponentially more capacity. So taking advantage of breakthrough technology doesn’t mean you have to replac your infrastructure.

With the launch of Everon™ Network Solutions, Corning has flexible solutions that solve complexity in every part of the network, end-to-end: across fiber to the home (Evolv), data center (EDGE), and now, enterprise. Everon™ is the latest result of Corning’s 50 years of continuous innovation to increase the speed and capacity of the optical networks it invented, all while reducing installation costs.

Fluke Networks: Metal LC Connectors for Test Cords

Fluke Networks designs, develops and commercializes fiber optic test equipment used in the field to certify, verify, or qualify installed fiber optic cabling. In all cases a test cord is required. For OTDR’s, this cord provides distance from the OTDR to allow it to measure the first connector in the link; for loss testers, the cords provide reference-grade loss performance for more accurate measurements. Test cords need to connect to the final installation and in many instances, that means LC type connectors.

Standard LC connectors are designed to be used a few dozen times and are rather flimsy and can break easily. That is perfectly acceptable for cords connecting devices in a network which move only a few times over the life of the installation, but for installers who need to test large quantities of links with expensive cords, it is a source of dissatisfaction. Breaking an LC connector on an expensive, high performance test cordtest cord means purchasing a new test cord.

Fluke Networks has designed and patented the first and only Metal LC Connector that is compliant with the IEC 61754-20 and TIA-604-10B intermateability standards and passes rigorous testing including GR-326-CORE testing, durability testing, and extended latch testing. The new LC Connectors have been tested for up to 10,000 insertions without noticeable wear on the plastic adapter.

The new Metal LC Connector comes standard on all Fluke Networks LC test cords.

Legrand: The Compact Edge Cabinet (CEC)

User Focused Features and Benefits:

- Wide Open Access: When opened the back-pan, equipment, and connectivity remain in place – while the enclosure swings out allowing unfettered accessibility and management.

- PCI Compliance: User access is controlled by an integrated swing handle with lock.

- Certified Load Rating per UL2416: 135 lbs total (125 lbs per pair of mounting rails and 10 lbs on the door).

- Vertical Rack Mount: Enables low-profile mounting allowing for easy installation, access, and maintenance.

- Maximizing Space: Two pairs of 4 RU rails are supplied to mount a variety of network equipment, auxiliary equipment, power and panel. One Pivoting Panel Mounting Bracket Kit has been supplied to free up vertical space and improve access to the rear of installed patch panels. (Additional kits sold separately - CECPPM1RU)

Panduit: TX6A FieldCord Connectors

The TX6A™ FieldCord™ Connectors are part of a simple connection solution for nearly any RJ45 plug-attached network device. The UTP FieldCord connector combines a novel field-mateable splice, the industry’s smallest diameter Category 6A twisted pair, 23 AWG cable, and an ultra-compact RJ45 plug all in one assembly.

The FieldCord connectors enable connection to devices with the smallest port spaces and most confined cable routing paths. These connectors provide Category 6A performance while also compatible with Category 6 and 5e systems.

The FieldCord’s splice re-termination can re-terminate up to 20 times with no additional parts, providing convenience and cost-savings. The same forward-motion termination technology used in Panduit’s Mini-Com® TG Modular Jacks is also used with the FieldCord connectors. This enhanced termination technology delivers proven electrical performance and quick installation.

The small plug size allows the connector to easily fit in tight port spaces of network devices where other connectors are often too large. With a 22-26 AWG termination, the FieldCord connectors work with all commonly used solid or stranded cabling.

TX6A™ FieldCord™ Connectors are built to deliver robust flexibility throughout various connectivity solutions within your networks.

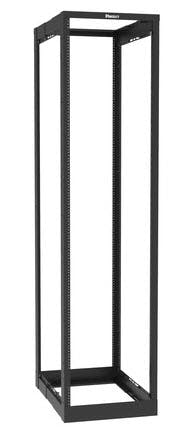

Panduit: Adjustable-Depth 4-Post Racks

The Adjustable Depth 4 Post Rack is part of a complete rack and cable management system that manages, protects, and showcases your network investment. The adjustable rack is designed to support network equipment found in data center and telecommunication room environments. The rack combines the stability of a cabinet with the accessibility of an open rack to provide the user with maximum flexibility when designing the network layout.

Upgrading active equipment in telecommunication rooms and data centers often requires a deeper rack. The rack can adjust depth to fit various network needs. Each rack has 39 different depth options from 23 inches to 42 inches in half inch increments. The adjustable depth 4 post rack system provides maximum versatility in a single part number. Bonus holes in the posts allow for various accessories to be mounted, such as PDU brackets, vertical patch panel brackets and vertical tie-off brackets to create greater application flexibility.

The adjustable rack can be assembled in minutes and is self-squaring when assembled with the option of eight different masked grounding locations at all corners of the rack. The rack feet face inward for reduced footprint and improved safety risk.

Siemon: LC BladePatch Fiber Jumpers with UniClick Technology

Siemon’s new LC BladePatch® duplex fiber optic jumper with UniClick™ technology represents a significant, user-focused advancement to the popular LC BladePatch product family.

These new UniClick enhancements work in conjunction with LC BladePatch’s exclusive, patented push-pull latch. This proven design allows the connectors to be securely engaged and removed via a finger grip on the exposed and easily accessible end of the strain relief boot rather than defeating traditional LC jumper thumb latches. Particularly in high-density applications with limited “finger space” between fiber patching ports, traditional jumper latches located at or close to the jumper-to-port connection point can be difficult to access without disturbing surrounding jumper connections.

Combining this innovative push-pull latch with a new space-saving, one-piece UniClick housing that reduces LC BladePatch’s already small footprint, these enhanced jumpers considerably simplify jumper installation and patching administration in even the tightest, side-stacked server, switch, and SAN port configurations.

The UniClick housing also improves on the LC BladePatch’s patented, user-friendly fiber polarity change process. With correct transmit-to-receive linkages between ports in connected devices and patching fields being essential to system function, correct jumper polarity is critical. Unfortunately, polarity is also a common source of confusion, and it is not uncommon for technicians to find themselves on the job site before realizing that they do not have jumpers with correct polarity for the equipment configuration. The LC BladePatch, however, features an exclusive design that allows polarity to be changed on the fly in the field.

While most fiber jumpers do not support field polarity changes, those that do typically require a technician disassemble the connector housing and physically move and twist the fibers, creating a strong risk of damage. LC BladePatch’s patented rotating latch design allows the user to change jumper polarity by simply rotating the latches 180 degrees around the fiber. The fiber itself is not twisted or disturbed in this latch rotation process, eliminating potential connector and fiber damage.

In the original LC BladePatch, accessing the rotating latches to change jumper polarity required a technician to remove an access clip to gain access to the latches. While this procedure was simple, it did require partial disassembly and introduce the risk of losing the removable access clip. The new UniClick equipped LC BladePatch simplifies the polarity change process even further, eliminating multiple components and steps by incorporating a single polarity reversal switch. In the UniClick version, technicians simply engage the polarity reversal switch, retract the outer housing and rotate the latches. The inner ferrule alignment frame remains in place, and the fibers themselves never move from their factory-terminated locations.

Siemon’s new LC BladePatch jumpers are compatible with any standard duplex LC adapter opening or LC small-form pluggable (SFP) module and feature superior connector polish that meets stringent Telcordia and ISO/IEC end-face specifications and exceeds all ANSI/TIA and ISO/IEC insertion loss and return loss requirements. Available in OM3 and OM4 50/125 Multimode and OS1/OS2 Singlemode, in both UPC and APC configurations, and in OFNR, OFNP and LSOH jacket constructions, every LC BladePatch is 100% factory inspected to ensure precise optical performance and defect-free operation.

SnapOne: WirePath Plastic Enclosure

Vertical Cable: 5-DoF Surface-Mount Equipment Bracket

5 DoF:

- Swingable at the base plane 0°–180°.

- Swingable at the base plane 0°–90° with fixed position at 90°.

- Swingable at the equipment mounting plane 0°–120°.

- Eight adjustable depth levels.

- Swappable equipment mounting flanges.

Cage nut mounting standard: Both bracket assembling and equipment mounting fasteners are based on cage nuts.

Advantages: Stripped thread does not become a problem that may limit the product’s functionality or even make it unusable.

Interoperability: installers can choose the type and size of the fasteners they are used to (e.g., USCU/metric, M5/M6, #10-32/#12-24, etc.).

Foldable: It’s foldable for shipping, takes minimum space.

In its folded state the bracket has dimensions and occupies space equivalent to that of a regular patch panel and can be packed using the same boxes.

Advantages:

- Savings on shipping costs - lower overall cost - lower consumer price.

- Savings on packing materials - lower overall cost - lower consumer price.

- Savings on storage/warehouse costs - lower overall cost - lower consumer price.

- Smaller packing - less trash - less problems for installers.

- Less packing trash - more environmentally efficient product.

- Less packing variety - more sustainable production.