Turn cable project qualifying into a big deal

By Deane Horn,

In a perfect world, every new structured cabling installation would be built and certified to TIA-568-D, and customers would be happy to pay for it. The reality is that most small to medium-sized enterprise network projects don’t have the budget—or frankly the need—to obtain this level of conformity or proof of compliance to global standards.

The TIA-568 standard covers just about every aspect of a cable installation, in effect setting out the “dos and don’ts” of structured cabling in the age of gigabit transfer speeds. The situation is fairly straightforward: When project specs invoke TIA-568, the entire project must be certified to make sure every “do” has been “done,” so to speak, and to document that the network was built to standard. Certification testing of the cabling is just a small part of the overall project. It involves testing every installed cable link with sophisticated testing equipment and requires at least one RCDD to do the job. For new builds that are not designed, architected and installed to global standards, there is no reason to certify the cabling. For cabling contractors, that leaves the matter of how to prove you did the job right, make money and retain that customer’s business.

There is another way to go about proving cable performance when certification testing is not part of the picture. It’s called qualifying, and until now such testing could only be done piecemeal with no ability to organize or document the work. With a next-generation qualifier, installers can label and autotest hundreds of cables per project at bit error rate test (BERT) up to 10 Gbits/sec with complete reporting. It’s called cable project qualification, and it’s a powerful testing solution to complement cable project certification.

What the need for speed really means

Data networks continually evolve against an ever-changing fitness landscape of users, applications and physical-layer constraints. Before we get into the details about network certification versus qualification, let’s try to summarize where we are.

The science and hardware of data transfer is constantly achieving higher speeds and bandwidth. With each new benchmark established in the lab or for mil-spec, standards catch up and costs go down as the new platform propagates in the marketplace.

New state-of-the-art installations require new learning on the part of cabling contractors, along with new techniques, unfamiliar products and often new testing devices.

In the field, slower networks are constantly being replaced with faster ones, but it is a moving target. Most commercial enterprises that can afford a major network upgrade expect it to remain viable for more than a couple years, making the majority of built networks one or two benchmarks in speed behind.

Network channel topology is changing rapidly. It used to look like highways or plumbing, with main lines connecting various branchings. Today’s networks are more like tent cities, with smart cameras, smart access, smart lighting, wireless access points, and low-voltage devices popping up everywhere and running on the same cables as voice and video. This stuff is getting cheaper all the time, and even small buildings will look like this after their next upgrade.

All but the largest data-driven enterprises must employ adaptive strategies for navigating such constant innovation over time. As a result, the typical commercial network that contractors are likely to encounter will be some combination of recent and legacy architecture with an upgrade initiative on the horizon. This last bit is important because, as we shall see, the advent of 10G qualifying lets contractors show customers the true potential of their existing structured cabling and make better decisions about when and how much to upgrade.

How certification and qualification fit together

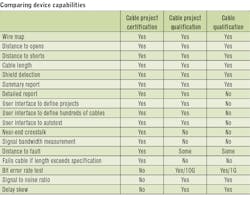

The main point of this article is to show how this new idea of cable project qualification—made possible by our project graphical user interface (GUI)—can help contractors to compete for bigger business while profiting from premium testing and documentation on cabling projects of all sizes. Project qualification does this by bridging the gap between conventional troubleshooting and certification. But to get there, we need to understand clearly the difference between certifying and qualifying, and how these two cabling test arrays fit together in the contractor’s arsenal.

To begin with, cable certification testing refers to the evaluation and documentation involved in making sure that the cabling portion of an installation, as well as the test methodology used in the certification process, all meet global standards. Once certified, anyone anywhere can rely on this cabled network to perform as expected without worries. And because everything was done right, manufacturers of cable and connectors will honor all warranties. Everyone gets paid; everyone feels protected. The lawyers are happy. Does your project need to meet this level of assurance? If you are cabling up a new Amazon distribution center, it does.

TIA-568 specifies the test setup, wiremap and signal-loss limits for different types of cable, link configurations, and channel lengths for both copper and fiber. For example, a copper cable channel must be 90 meters or less with additional 10 meters for patch cords, with no single patch cord exceeding 5 meters. Bandwidth limits are defined as follows.

- Category 5e: 100 MHz

- Category 6: 250 MHz

- Category 6A: 500 MHz

- Category 8: 2000 MHz

Once the correct limits are selected, each cable link is tested for bandwidth, insertion loss, near-end crosstalk (NEXT), and crossed/split/swapped wire pairs at connections.

If the certification test passes, you provide your customer with a report that shows wiremap, cable length, NEXT dB, insertion loss dB, and an overall pass for the project. Certifiers are designed to measure exact distance to fault, which is helpful in case the issue is at the connector right in front of you and not buried 18 feet beyond the wall.

Keep in mind that certification means evaluation of an installation to a set of globally accepted parameters that have been carefully vetted and defined. If there is some aspect of the design or installation that falls outside of these parameters, the network will not pass. Nor is it likely for properly installed cabling to pass if some part of the test was not performed correctly. It is possible for an underperforming installation to receive an overall pass if, for example, the wrong limits were selected on the testing device. This underscores the precise nature of certification testing and the importance of proper training.

Certifiers examine the physical characteristics of cable, connectors and bandwidth, and compare this information against limits defined by standards. The test itself requires that every aspect of each copper or fiber link must be correctly simulated with respect to the test device, including patch cords, connectors and polarity used in launching the signal. That speaks to the complexity of the instrument and the knowledge base required to perform certification correctly. The takeaway, however, is that the purpose of certification is to evaluate and document that a structured cabling installation will work as advertised.

Qualifying: Measurement of actual performance

Certifiers are not set up to measure the actual speed of data transfer, but to determine whether or not cable-link specs as installed meet or exceed predetermined limits. They are more expensive and complex to operate than other kinds of testing equipment because of the software and I/O features necessary for defining the characteristics of a wide range of installed cable against global standards. In short, it is overkill to use a certifier for anything other than certifying.

The need to check continuity and bandwidth, or determine the location and nature of a fault or signal loss in a particular link occurs far more often when you are not involved in certifying a project. These types of tests have traditionally been relegated to troubleshooting, a.k.a. qualifying. In the field, the two terms are used interchangeably for generating wiremaps, testing data-transfer speed, and identifying issues. The only real difference between troubleshooting and qualifying is that the average qualifier has a few more bells and whistles than a time domain reflectometer (TDR), and is handier for performing a number of different tests.For the cabling contractor, the gap between qualifying and certifying is considerably wider. Qualifying meant testing end-to-end performance, one cable channel at a time. Unlike certifiers, there is no way for a qualifier to organize and document results for the customer across the whole project. Our new GUI lets the user label, autotest and generate reports for hundreds of cable tests in a single project. Project qualifiers elevate cable qualification from fixes to a profitable, high-value service for new builds, moves and upgrades.

What a qualifier can’t do is issue a pass or fail based on limits set under TIA-568 or ISO/IEC 11801—something that is normally required in global specs and to validate manufacturer warranties.

You should be qualifying most often

It is absolutely vital for cabling contractors to be equipped with the technology and talent to certify structured cabling installations if you plan to compete for big projects, like data centers, new office buildings and commercial or educational campuses. Most of your cabling business, however, will be smaller offices, upgrades or changes that don’t require certification. At least 80% of those jobs require more than simple continuity testing or your customers aren’t getting their money’s worth and you’ll be coming back to fix things on your own dime.

This is the cable qualifying space. Qualifying is very thorough, but much simpler to accomplish than certification. Technicians simply connect a cable to the local and remote units and click through the autotest and labeling function, then move on to the next cable. The devices are much less expensive than certifiers, and anyone can be trained to use one properly. But here is where it gets interesting. We have built a project creator/editor into the software of our qualifying tool, the NetXpert XG qualifier. With this capability in hand, you have a powerful multi-tool that can test copper, fiber, and wireless from local or remote. It allows you to label every cable tested, and to print, store or upload reports.

Measuring actual speed reveals potential speed

Remember what we said earlier about typical enterprise networks being a combination of older and newer cabling? Qualifiers test a cable channel by sending real data. Essentially, you are demonstrating how well a customer’s network actually works. But by testing various parts—trunks versus patch panels, for example—you can also show why, and in most cases where, it could be running faster than it is.What we have found by launching a 10G qualifier is that many networks previously certified to run at 500 Mbits/sec or 1 Gbit/sec were actually able to run at much higher speeds. This demonstrates another difference between certifying and qualifying, and why both are important. Networks are designed with equipment, including hubs, switches, and patch cords, that are certified and warranted to a specific standard. Category 5e cable, for example, has the physical layer capability to run at 2.5G, even though the network was designed and certified to operate at 1G. With 10G qualifying, it becomes possible to know ahead of time if newer topologies calling for fewer patch cords and high-speed switches and wireless access points can achieve higher network speeds without replacing permanent links. If so, it is a huge savings for the customer. If not, cable contractors can show customers exactly what their networks are capable of and how the economic scenarios of upgrading and replacing play out. Either way, decisions are made with fewer unknowns. This is powerful.

10G qualifying and the bigger picture

BERT capability up to 10 Gbits/sec gives cabling contractors a lot of headroom for measuring signal degradation, such as delay skew, that becomes more significant with tighter tolerances of Category 6/6A cabling and bit rates over 1 Gbit/sec. If you use Softing’s NetXpert 10G, the large screen and clear graphic layout of the wiremap and SNR graphs make it easy to spot crossed pairs, wire swaps, and spikes in crosstalk that are likely indicators of connector faults.

10G project qualifiers make it convenient for contractors to address active network issues posed by smart buildings and wireless connectivity at small to medium-sized customer sites where moves, adds and changes are more frequent. Capabilities include network discovery, Power over Ethernet load test, device identity and priority detection, LLDP/CDP detection, duplicate IP address detection, long-term BERT and continuous wiremapping. The units have plenty of memory, and test results and reports are transferable via USB flash drive.

The bottom line: Cable certification and cable project qualification fit together to form a formidable testing arsenal. Roughly 20% of projects contractors compete for will need to be certified. Almost every other job—restaurants, doctors’ offices, municipal buildings—can be enhanced with the testing, management and reporting capabilities of next-generation project qualification. By performing both certification and qualification, your projects, labeling and reports are generated in a common format and saved to the same cloud. It’s the kind of business efficiency and service your customers will appreciate and come to expect.

Deane Horn is director of product management and marketing with Softing Inc.