Handheld tools advance to ease the troubleshooting process

By Patrick McLaughlin

A combination of enhancements to existing products and the introduction of new products has made the task of troubleshooting installed cabling systems less arduous than it historically has been. This article looks at a few recent technological developments that are examples.

In an article published to the cablinginstall.com website in late September, Softing described the purpose, capabilities, and price variations among different cabling-tester types. Within that article, titled “Do I really need different cable testing devices,” Softing noted, “Higher speeds are the result of technological refinements that increase various interactions in the physical and data layers of a cable link over shorter periods of time in the same amount of space. The complex interweave of materials, signal and math is the primary reason devices for testing LAN links have become so sophisticated.”

The article then explained, “One of the simplest cable tests, called wire mapping, sends a signal down the link to see if anything is wrong, broken or missing. A method called time domain reflectometry measures the speed of the signal and maps the channel topology, precisely locating the number of possible faults. Sometimes called TDRs or verifiers, these wire mapping devices are the equivalent of a pocket knife and should be hanging from every technician’s belt. A somewhat more useful foundational cable testing device will be able to detect Power over Ethernet (PoE) and capture any networked phones, cameras or other low-voltage devices in the wire map.”

Verifiers and qualifiers

Tim Widdershoven, global marketing manager at Ideal Networks (idealnetworks.net), recently commented about wire map testing and the tools used to conduct it. He noted, “Installers have been using LED cable verifiers, or blink boxes, to conduct wire map tests for years as they are easy to use and suitable for identifying common faults. However, with today’s more complex cable infrastructure, LCD verifiers are the best choice for the majority of installers and can help to improve efficiency.”

Unlike LED verifiers, which require a user to decode a sequence of blinking lights to identify a cabling fault, the display panel on an LCD verifier has “intuitive graphics to provide far more comprehensive details on cabling faults, allowing for faster repair,” Ideal Networks noted. “LCD verifiers can display information such as cable length, distance to opens or shorts, crossovers, split pairs, connection speed on live networks, analog-versus-digital phone service and PoE status.”

The company and Widdershoven made these comments within the context of discussing Ideal’s VDV II product line, which includes three models: VDV II, VDV II Plus and VDV II Pro. “VDV II Pro uses TDR to obtain more-accurate measurements more quickly,” the company explained. It also offers built-in network detection to help identify connection issues that are caused by a media service such as ISDN, PBX or PoE, rather than a cable fault.

In its online article, Softing took the conversation up the network stack a bit. “The next step up in verifiers enables the technician to troubleshoot the network by identifying specific faults in both the physical and link layers in a channel. In addition to broken or split wires, bad connections or other issues associated with the signal itself, the tester will perform a network discovery that tests the data protocols at each link to make sure all devices on the network are properly identifying one another.

“Whether you are installing a new run or troubleshooting a faulty one, someone is going to need to test both the physical and link layers and prove that the network is operating to specifications,” Softing continued. “That takes us to a considerably higher level of testing, typically called qualification or transmission testing … As a practical matter, certification [to TIA and/or ISO/IEC cabling specifications] only happens after everything has been installed, fixed and tested. This leaves a lot of situations short of certification where the testing and reporting capabilities of a certifier could come in handy. That is the space occupied by qualifiers.”

Softing offers the NetXpert qualification test set, which the company explains “does all the troubleshooting of cable/network testers with one very important addition: It can verify Gigabit Ethernet operation compliant with the IEEE 802.3ab standard. It does this through bit error rate test (BERT), a form of data transmission testing that sends 1 Gbit/sec, counts the errors, then issues a pass/fail. While distinct from certification, a BERT pass essentially proves the speed of a cable channel is up to standard.”

The company further noted that the cost of a qualifier typically is less than one-third that of a certifier, and therefore “it makes sense for every cabling crew to pack a network qualifier. On the other hand, at about twice the cost of a cable verifier it’s overkill to have everyone using them for routine wire mapping and troubleshooting. Every cabling contractor location should have at least one certifier under a service contract plus one backup. Every crew needs to have a qualifier available to test the fix. Every technician should be carrying a cable verifier, whether they are part of a cabling contractor crew or a facilities management team.”

Fiber troubleshooting

The testing of installed fiber-optic cabling systems is divided into methods called Tier 1 and Tier 2. In a white paper titled “The Rise of Tier 2 Testing,” Viavi Solutions explains that, in essence, Tier 1 tests a fiber link for length, polarity, and link loss. “While Tier 1 tests can identify problems in terms of pass or fail, they cannot determine the root cause or location of the problem,” Viavi says. “Tier 2 testing is used to pinpoint root-cause locations and the amount of loss, ORL [optical return loss], or reflectance from each problem contributor. The OTDR is used to perform Tier 2 testing.

“It’s important to understand that Tier 2 testing does not replace Tier 1,” Viavi continues. “It is performed selectively in addition to Tier 1 testing under specific conditions and situations. Tier 2 testing provides a deeper level of link visibility, unlike any other fiber infrastructure tests.”

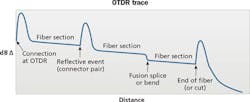

The paper focuses to some extent on the use and functionality of the OTDR, optical time-domain reflectometer: “The OTDR provides the unique ability to visually see and map the link and any passive events over its length,” Viavi explains. “The OTDR sends an optical test pulse over the fiber. Similar to radar, a small amount of this energy is scattered, or reflected, some of which returns to a detector in the OTDR. This reflected energy is mapped based on its round-trip travel time converted to distance, based on the speed of light in optical glass.

“OTDRs have a reputation of being complicated and intimidating for network technicians. Learning to read a trace might look easy to more-experienced users, but it can be complex, especially when various factors cause confusing results. Setting up OTDRs to test accurately also requires knowledge and experience. Knowing what you are testing, and translating that knowledge to the right test setup, can take years to master.”

However, the paper notes, new advances have simplified OTDR testing. Specifically, preconfigured instrument setups, easier-to-read schematic test results, and better documentation are characteristic of the newest-generation OTDRs and make the task of Tier 2 testing easier to accomplish than it traditionally has been. “Much effort has gone into the OTDR user interface design, making the tool much easier to use,” Viavi notes. “Technicians can operate many modern OTDRs easily with very little training because of new software enhancements.”

Fluke Networks added capability to its OptiFiber Pro OTDR that gives the unit the ability to test two separate fiber links in both directions from one end in a single test. “With SmartLoop, users no longer need to walk the OTDR to the far end of the link to perform bidirectional tests, helping contractors squeeze more profitability out of each project,” the company explained. “Experts and standard bodies know that bidirectional averaging is the only accurate way to perform OTDR measurements. Without it, there is a risk of false failures and wasting time troubleshooting problems that aren’t there. But customers are reluctant to do it because of the time and complexity. The new SmartLoop technology makes it easy and fast to perform this crucial function.”

Linking labeling

In addition to developing technology innovations that simplify or improve the testing process, Fluke Networks recently collaborated with cable-labeling producer Brother Mobile Solutions to create LabelLink, a mobile app-based jobsite workflow tool that allows the printing of labels directly form data generated as part of the testing process. LabelLink is built on Fluke Networks’ LinkWare Live cloud-based storage and management system. “The application effectively marries Fluke’s LinkWare Live cloud technology with Brother’s PT-E550W WiFi industrial labeling tool to perform multiple functions with a single entry of cable identifier data,” Brother Mobile Solutions says.

“Adhering to industry standards and best practices in datacom network planning and design, as well as installation and identification of the physical layer infrastructure, calls for precise and accurate labeling of all cabling and connectivity components,” the company continued. “The larger and more complex the project, the more specific, complete and consistent component labeling must be. For this reason, close coordination is needed between system designers, testers and their installers to ensure that the project’s execution at the jobsite precisely matches the design plan.”

Brother explains that the LabelLink application works as follows: 1) In the office, the project manager uses CAD to plan the network infrastructure, then uploads cable ID and component identifiers to LinkWare Live; 2) The project manager can use LinkWare Live to define detailed test settings for the job; 3) Technicians download and install the LabelLink app on their smartphones; 4) On the jobsite, the contractor or technician uses their smartphone to download cable identifiers from LinkWare Live into their Brother PT-E550W labeling tool, which is used to create labels; 5) Also on the jobsite, the contractor or technician downloads the same identifiers and testing limits into the Fluke Versiv Cabling Certification System, performs the tests, and uploads testing results for each identifier to LinkWare Live.

Brother further explains, “Using a single, centralized database removes multiple additional steps, and eliminates the chance of transcription errors and confusion, and makes it much harder to miss testing links or test them multiple times. It can also prevent delays when experts are called to the site to make sure tests are set up properly. This is especially valuable on large jobs, where multiple technicians are using multiple testers and labelers, and the chance of mistakes is greatly increased.”

With the product enhancements and introductions described in this article, test technicians have more and more-efficient means to identify, locate, and in some cases even prevent faults that degrade cabling-link performance.

Patrick McLaughlin is our chief editor.