Designing and installing fiber-optic cabling to support distributed antenna systems

By Eric R. Pearson, CFOS/C/S/T/I, Pearson Technologies Inc.

A distributed antenna system (DAS) is a wireless communication system that replaces the single, high-output-power, cell-phone antenna with multiple, reduced-power antennas. It is, in effect, a mirror of the cell phone network, but with a reduced coverage area.

Distributed antenna systems are implemented in confined areas, such as campuses, sports stadium, and areas with small concentrations that require high capacity and may have dead zones or zones of low signal strength.

There are four basic reasons for DAS use: 1) Insufficient signal strength; 2) Insufficient bandwidth; 3) Adding value; 4) Legal requirement.

The two causes of insufficient signal strength are the signal absorbing or blocking materials in and within buildings, and dense buildings blocking the signal path.

In indoor locations, modern building materials block or degrade wireless communications signals creating “dead zones” (not be confused with optical time-domain reflectometer dead zones). This situation exists in many modern office buildings, tunnels, mass transit systems, and event and sports arenas. In this situation, a DAS extends communication capability with multiple antennas placed in locations in which the wireless signal is weak.

In indoor locations, high building-density can interfere with wireless signals. A DAS distributes the signal unreachable by the cell phone tower. Outdoor arenas and sports venues have high bandwidth requirements. By dividing the coverage area into areas of reduced size served by individual antennas, a DAS enables increased bandwidth per user.

In some indoor and outdoor locations, such as event arenas, the signal strength may be sufficient but the bandwidth is not. In this situation, multiple antennas segment the bandwidth by localized regions. By reducing the number of users per antenna, a DAS multiplies the effective bandwidth per user by the number of antennas.

Because an estimated 80 percent of all cell phone traffic begins or ends inside buildings, in-building cell phone access is important. Some wireless carriers install DAS inside certain buildings to enhance their service offering. In addition, some building owners add value to their real estate assets by installing a DAS. A side benefit is increased cell phone battery life, as the phone can use reduced power to maintain a connection.

Some municipalities require new buildings to provide reliable wireless service. This service is for emergency services personnel, including police, fire, EMTs and 911 location service.

Configurations

Distributed antenna systems are variously known as small cells, microcells and femtocells. The designation depends on the coverage radius.

All DAS start with one of two inputs: a connection to a carrier via fiber-optic cable; or an antenna, called a donor antenna, that receives from and transmits to the cell phone system.

This antenna is located such that there is no communication interference or blockage. Typically, this location is outdoors and above the tree line. Typically, this antenna receives multiple frequencies to increase capacity and enable emergency communications.

This antenna connects to one of two types of equipment: a bidirectional amplifier or a repeater, usually located in an equipment room known as the “head end” equipment room. The amplifier amplifies the signal to provide strength and reliability sufficient for the facility. A repeater repeats the signal without amplification.

The signal is distributed from the equipment room to the antenna nodes. These nodes occupy locations that provide the desired coverage. Determining these locations by survey is the most important factor in providing acceptable service. Such distribution is over coaxial cable or fiber cable.

Small systems use coaxial cable to create a “passive” DAS. The coaxial is “leaky” so that the cable functions as the antenna. However, modern building materials can block such relatively weak signals.

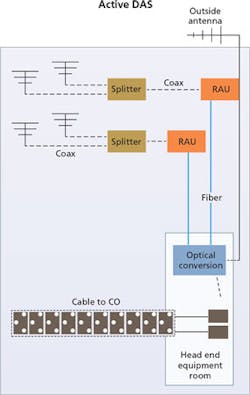

Large systems use fiber cable to create “active” systems. The optoelectronics convert the incoming radio frequency (RF) signal to a digital optical signal, with return to RF at the distributed antennas. Such transmission can be analog or digital.

However, the preference is for digital transmission. This preference is driven by cost; digital transmission is less expensive to implement and operate than analog. In addition, digital transmission can be repeated without limit. In comparison, analog signals have limited repetitions, since the signals gain noise and distortion with each repetition or amplification.

The current configuration includes both coaxial and fiber cables. This configuration is fiber cables feeding digital signals to remote antenna units (RAU), which, in turn, feed multiple antennas over short coaxial cables. RAUs are also known as RRUs (remote radio units), as in fiber-to-the-antenna systems.

The use of fiber, which has essentially no power loss, to the RAUs, results in all antennas having the same sensitivity and power, regardless of their distance from the head end equipment room. This is not the case with systems connected with coaxial cable.

Most DAS transmit digital signals with the Common Public Radio Interface (CPRI) protocol. Most companies producing DAS and FTTA equipment use this protocol.

DAS have the same architecture as do local area networks (LAN). In addition, DAS use the same fiber and cable types. Because of these common characteristics, a DAS and a LAN can share the same cables and structured cabling system. Such cables can have both multimode and singlemode fiber. In most current-day systems, the advantage of potential increase in bandwidth without limit favors the use of singlemode fiber.

Because of the low optical power loss, DAS can be implemented as a passive optical network (PON). With this approach, each RAU requires a single fiber with wavelength-division multiplexing (WDM) to enable bidirectional communication.

Design concerns

As distributed antenna systems us the public radio spectrum, all distributed antenna systems involve a cell phone provider, also known as the carrier. Most DAS provide service to only the owning carrier. Others provide “carrier neutral” service; that is, the DAS allows communication to multiple carriers. For such a DAS, the entrance facilities and head end equipment room space requirements are higher than those for a carrier-owned system.

Most designers of communications systems prefer to work from appropriate standards. While such an approach simplifies the design process, the number of variables in design and in the conditions within which DAS must function conflict with the two goals: 1) economy of implementation and 2) efficiency in use. While no DAS standard exists, the Telecommunications Industry Association (TIA) developed Telecommunications Systems Bulletin TSB-5018 Structured Cabling Infrastructure Guidelines to Support Distributed Antenna Systems. That document was published in July 2016.

Key design concerns for DAS include the following.

- Number of carriers/service providers

- Entrance facilities

- Head end room size

- Site survey to determine signal propagation

- Antenna locations

- Prefabricated or field termination of cables

The number of carriers determines three aspects: the size of the entrance facility; the head end room size; and the types of antennas. The required equipment determines the facility size. The number of carriers determines the frequency range requirement of the antennas.

The survey of the building or outdoor space identifies the signal propagation of all areas to be serviced. At least two characteristics determine the propagation: coverage area size and blockage, and absorption of construction materials.

Two factors determine the decision between preterminated cables and field termination: the distribution of cables, both coaxial and fiber; and ease of cable installation. Preterminated cables tend to have cost lower than that of field termination. Field termination has increased labor cost due to increased hourly labor rates and reduced labor utilization.

If accurate cable lengths are known, the choice will favor preterminated cables. If the cables can be easily installed, such as up unoccupied vertical conduits, above removable ceiling tiles, and between wall studs prior to wall installation, cables can be installed without damaging fibers or connectors. With both well-known lengths and easy installation, preterminated cables are usually the choice.

Installation concerns

Cables are of two types, preterminated and not. During installation, preterminated cables require care to avoid damaging both the cable near the connectors and the connectors. One method of avoiding damage is enclosing the connectors in a shroud that prevents the connectors from snagging. The shroud is temporarily attached to the cable and removed after installation.

A second method to avoid damage is the installation of cable preterminated on one end. The unterminated end is pulled into location, eliminating stress on a preterminated end.

Preterminated or not, cable installation requires attention to the three most important cable characteristics: installation load and the two bend radii. Because damage is easier in bending than in tension, installers need to be more careful in bending than in load limiting.

Installers can install connectors by any one of seven methods: 1) epoxy, 2) HotMelt adhesive; 3) quick-cure adhesive; 4) crimp and polish; 5) cleave-and-crimp; 6) fuse-on; 7) pigtail splicing. However, two methods dominate DAS installations - fusion-spliced-on pigtails and no-polish connectors.

No-polish connectors or prepolished connectors are also known as “spliced connectors,” as the two types involve making a splice. Splice-on connectors require a fusion splicer for installation. “Cleave-and-crimp” connectors require a specific tool to make a mechanical splice in the back shell.

Testing concerns

Prior to testing, the installer cleans and inspects the connectors. Prior to installation, the installer tests preterminated cables. Such testing verifies lack of damage during shipping.

While one could assume that the caps contain no dust and that the caps have been on the connectors for the entire time from assembly to delivery, such assumptions are often untrue. Caps can contain dust. Caps can fall from connectors during shipment. Novice installers can wipe connector ends with wrong material, and even with fingers. Think of the “wonderful” microscopic appearance of a connector with skin oil and hand lotion on the core.

Microscopic inspection - Dust on connectors is a common problem. This dust blocks or diverts light from its normal path. In addition, it can prevent connectors in a patch panel from making full contact. Without full contact, connectors exhibit increased loss and reflectance. Finally, dust can create scratches on the fiber core when two connectors mate.

Dust has six sources: 1) dust not removed by pretermination facility; 2) dust from inside dirty caps; 3) dust from connectors without caps for any length of time; 4) dust transferred from dirty test leads; 5) dust from unplugged patch panel or optoelectronic ports; 6) dust from cleaning with tissues that are not lens-grade and lint-free.

In short, dust is the demon of fiber-optic connectors.

Test leads - The installer matches the test leads and launch cables to the fiber core diameter and to the connector type of the cables under test. In addition, test leads are qualified to demonstrate acceptable low loss. Dirty or high-loss connectors can produce only high-loss measurements. High loss results in rejection of the cables under test.

Insertion loss - The installer performs the insertion loss test in order to simulate the loss of the transmitter-receiver pair. The installer performs the insertion loss test according to the standard test procedure. For both singlemode and multimode testing, the recommended procedure is the one-lead reference method. In the singlemode test, the installer makes a 1.2-inch-diameter loop on the source lead. In the multimode test, the installer uses one of the two encircled-flux-compliant methods to measure the input power level.

In troubleshooting or initial link certification, the installer measures the output power of the transmitter and/or the power level at the receiver. For this measurement, use the dBm scale of the meter of the OLTS.

OTDR - While DAS cables and fiber-to-the-antenna cables serve the same function, with much of the same equipment, there is one potential difference: length. Fiber-to-the-antenna cables are relatively short and require a high-resolution OTDR. DAS cables may be short. However, they can have significant length in large buildings or outdoor distributed antenna systems. Long cables do not require a high-resolution OTDR.

To accurately measure short cables, the installer uses a high-resolution OTDR. Without one, the installer may not be able to measure individual connector pairs and segment lengths.

The installer performs the OTDR test with either one or two launch cables, depending on whether or not the requirement is to measure the loss of the far-end connector from the near end.

If the cable contains splices, the installer tests in both directions to determine the true splice loss, to identify ghost reflections, and to verify that gainers have acceptable loss.

The installer tests at a minimum of two wavelengths. Typically the lower wavelength is that of the optoelectronics. A comparison of losses at the short and the long wavelengths reveals the presence or absence of stress on the fiber.

In summary, DAS and fiber-to-the-antenna systems have similarities and differences. They are similar in their functions, in their concern for connector cleanliness, and in the types of testing performed.

They can differ in the cable lengths and size of areas served. In addition, they differ in the types of cables used. Distributed antenna systems use standard data communications cables. Fiber-to-the-antenna systems use custom hybrid cables. Finally, they differ in the method of connector installation. DAS cables can be field-terminated; fiber-to-the-antenna cables are usually factory-terminated.

Eric R. Pearson, CFOS/C/S/T/I is principal of Pearson Technologies Inc. (www.ptnowire.com). This article is excerpted from Chapter 31 of Pearson’s recently published book “Professional Fiber Optic Installation - The Essentials for Success, Version 10.”